Key Takeaways

- Generative AI transforms predictive maintenance by analyzing real-time machine data, spotting early failure signs, and helping teams act before breakdowns occur—saving time, money, and effort.

- It creates synthetic failure scenarios when real-world breakdown data is limited, improving model training and ensuring accurate predictions for new and old equipment.

- Simulating “what-if” scenarios with generative AI helps teams plan, understand machine behavior, and avoid critical failures before they happen.

- Automated recommendations and root cause analysis from generative AI enable faster, more targeted maintenance decisions, significantly reducing downtime and repair costs.

- Getting started with generative AI is easier today, thanks to IoT sensors, cloud platforms, and pre-built AI tools—no deep tech expertise is needed.

Many manufacturing firms rely on machines to ensure continuous production and minimal interruptions. However, thinking about what will happen when equipment breaks down can be stressful. As a result, there are various production delays, and manufacturers tend to spend more money. This is why they need to utilize predictive maintenance to check the health of machines and fix them as a priority.

Predictive maintenance identifies signs of wear and tear with the help of machines and sensors. This way, manufacturing firms handle maintenance and inspections at a suitable time. However, with generative AI, predictive maintenance is getting better than before. It is a type of artificial intelligence that helps identify huge data sets and prepare new insights.

The best part? Manufacturers can utilize generative AI. Several cloud platforms and artificial intelligence tools have made integrating them into existing systems simple. With proper support and guidance, factories of all types can start using generative AI.

Also read: Generative AI for Dynamic Data Modeling in Enterprise Cloud Solutions.

How Generative AI Improves Predictive Maintenance?

Predictive maintenance helps factories keep machines running smoothly by spotting early warning signs of problems. With the power of generative AI, this process is now more innovative, faster, and more reliable. Let’s briefly summarize the key ways generative AI improves predictive maintenance.

1. Better Data Understanding

Machines have sensors that collect a lot of data. These sensors track things like:

- Vibration

- Temperature

- Pressure

- Noise

- RPM (rotations per minute)

This data helps us understand how the machine is performing. But there’s so much of it that it’s hard for humans or traditional software to find minor problems. That’s where generative AI steps in.

Generative AI can process years of machine data in seconds. It can notice tiny changes, like a slight increase in vibration, that may seem normal at first. However, compared to past data, AI might say, “This small change usually means the motor will fail in about 10 days.” This early warning helps teams act before the machine breaks.

2. Creating Synthetic Data

One challenge in predictive maintenance is often insufficient failure data, especially for new machines. Without enough examples of breakdowns, it’s hard to train AI models.

Generative AI solves this by creating synthetic data—artificial examples of how machines might fail. It uses what it has learned from other machines and applies that knowledge to fill in the gaps.

This helps train better AI models, even when real failure data is limited. As a result, predictions become more accurate.

3. Simulating “What-If” Scenarios

Imagine asking, “What if my motor starts running hotter than normal?” or “What if a part wears out too soon?”

Generative AI can simulate these situations. It can show how the machine might behave and what kind of damage might happen. This lets the maintenance team prepare in advance and take action to avoid problems.

These simulations help teams answer questions like

- Will the machine shut down?

- How much time do we have before failure?

- What’s the best repair strategy?

4. Automated Maintenance Recommendations

Sometimes, it’s unclear what action or when to take it. Generative AI can help by giving straightforward suggestions based on machine conditions.

For example, it might say:

“Replace the left-side bearing in Machine #2 within 5 days to prevent downtime.”

This allows maintenance teams to focus on the right tasks at the right time, saving time and money.

5. Faster Root Cause Analysis

When a machine does break down, it’s essential to find out why. This process is called root cause analysis, and it can be time-consuming.

Generative AI can quickly look through logs, sensor data, and past maintenance reports. It can explain what happened and why, in simple language. For instance:

“The failure was caused by overheating due to blocked airflow over the past 3 days.”

This helps engineers fix problems faster and avoid repeat issues.

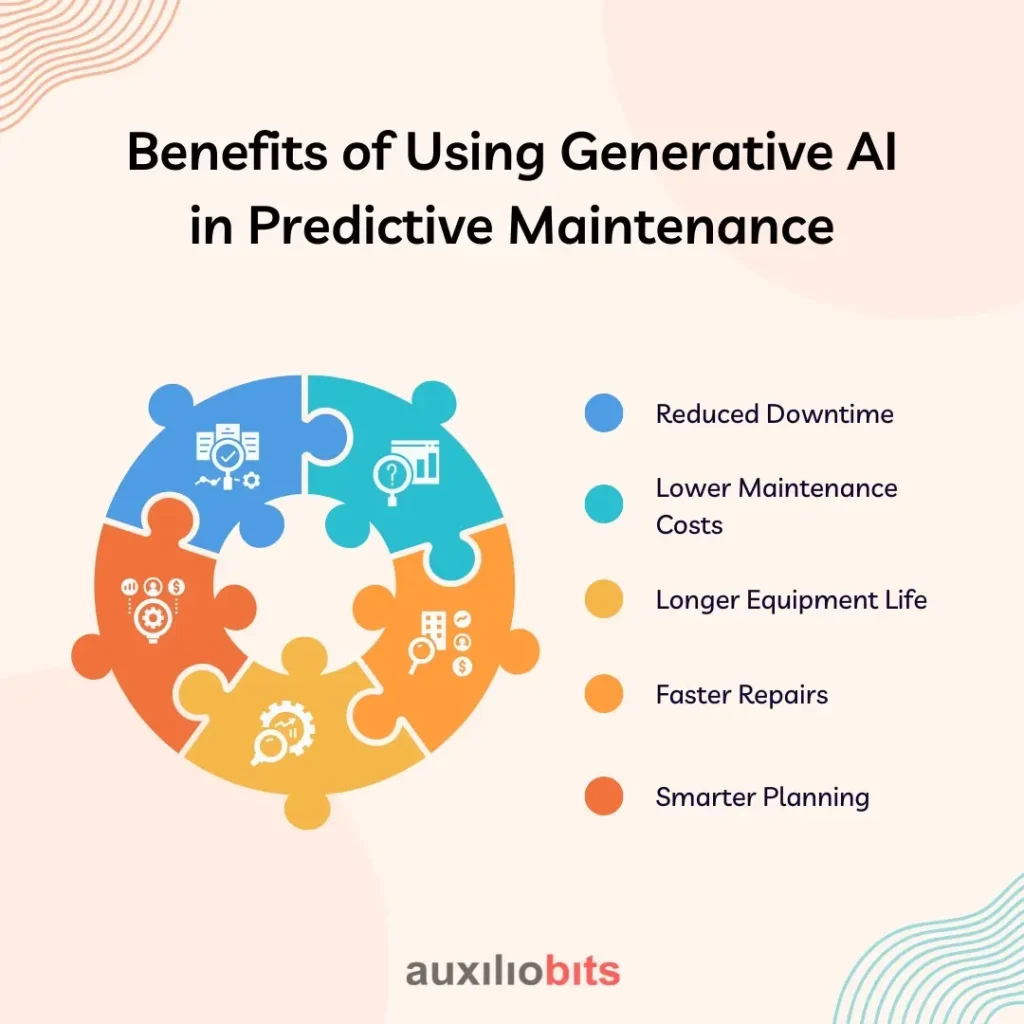

Benefits of Using Generative AI in Predictive Maintenance

Using Generative AI for predictive maintenance brings many valuable benefits to manufacturing companies. It helps make machines more reliable, reduces costs, and improves teams’ management of maintenance tasks. Let’s take a closer look at these benefits in simple terms:

1. Reduced Downtime

One of the most significant problems in manufacturing is unexpected machine breakdowns. When a machine stops working suddenly, production has to stop, which can be very costly.

Generative AI helps fix this by spotting warning signs before the machine fails. For example, if a part starts to wear out or a motor gets hotter, AI can detect it early and send an alert. This allows technicians to take action before it turns into a serious issue. As a result, machines stay running longer, and companies avoid costly delays.

2. Lower Maintenance Costs

Traditional maintenance often follows a fixed schedule, like checking a machine every month, even if nothing is wrong. This can waste time and money.

With Generative AI, maintenance is done only when needed. The AI looks at real-time data and tells you exactly when a part needs to be repaired or replaced. This innovative approach helps companies avoid unnecessary maintenance and save money on parts, labor, and downtime.

3. Longer Equipment Life

Machines tend to last longer when maintained based on actual usage and condition.

Generative AI monitors every machine’s performance and health. It ensures parts are replaced at the right time—not too early, not too late. This reduces wear and tear, helps avoid overuse, and extends the life of expensive equipment.

4. Faster Repairs

If a machine does fail, finding the cause can take hours or even days. Generative AI can quickly analyze logs, sensor readings, and maintenance records to determine what went wrong. It gives technicians clear answers, helping them fix the problem faster and get the machine back up and running with less downtime.

5. Smarter Planning

With predictive insights, companies can plan their maintenance activities. Generative AI can suggest the best times to repair or service machines based on current conditions and usage trends. This helps teams schedule work efficiently, avoid last-minute rushes, and manage resources better.

How to Get Started with Generative AI for Predictive Maintenance?

Starting with Generative AI in predictive maintenance may sound complex, but it can be done step-by-step. Even if you’re not a tech expert, the process can be smooth with the right tools and support. Here’s a simple guide to help manufacturers begin their journey toward smarter maintenance:

1. Install IoT Sensors

The first step is to collect data from your machines. IoT (Internet of Things) sensors must be installed on the equipment. These sensors monitor things like:

- Temperature

- Vibration

- Pressure

- Speed (RPM)

- Noise

These small devices constantly gather information about how your machines are running. This data forms the foundation of predictive maintenance powered by AI.

2. Connect a Data Platform

Next, you need a place to store and manage all this sensor data. A cloud-based data platform is ideal because it’s secure, scalable, and accessible anywhere.

Platforms like Microsoft Azure, AWS, or Google Cloud allow you to organize and prepare sensor data for AI analysis. These platforms also offer built-in AI and machine learning tools, making the process easier.

3. Train AI Models

Now it’s time to teach your AI system how to understand the data. This step is called model training. You’ll need:

- Historical data (past performance and failure events)

- Synthetic data (created by generative AI to simulate rare failures)

The AI model will learn patterns in the data, such as how machines behave before they fail, and use that knowledge to make future predictions.

4. Monitor in Real-Time

Once your AI model is trained, connect it to live sensor data. Use the ThilWhiler system to monitor machines in real time and detect early signs of trouble.

Generative AI will continuously analyze incoming data and look for unusual patterns. If it spots a potential issue, it will alert the maintenance team before the machine breaks down.

5. Take Action

The most important part is using the AI’s insights. Follow its maintenance recommendations, simulate “what-if” scenarios, and plan repairs based on the AI’s guidance. This ensures you’re always one step ahead of failures.

Final Thoughts

Predictive maintenance is already a game-changer in manufacturing. But with generative AI, it’s becoming even more powerful and proactive. From predicting failures to simulating different outcomes and generating intelligent recommendations, generative AI helps manufacturers save time, reduce costs, and avoid surprises.

Whether you run a small workshop or a large factory, this is the right time to explore how generative AI can take your maintenance strategy to the next level.