Procurement has always walked a strange line. On one hand, it’s supposed to be strategic—driving cost savings, strengthening supplier relationships, and even influencing innovation pipelines. On the other hand, the day-to-day reality often looks like an administrative grind: matching purchase requisitions with policies, ensuring approvals, raising purchase orders, chasing signatures, then juggling supplier communications.

That administrative weight is precisely why companies are investing heavily in “smart” purchase order (PO) automation. But the term itself—smart—has been stretched thin. Many vendors slap it onto workflow tools that simply move forms from inbox to inbox. In reality, making procurement genuinely intelligent means rethinking the entire lifecycle: from the first request for goods or services all the way to the moment a supplier is awarded the business.

Key Takeaways

- Automation fixes, but doesn’t erase, messy requisitions – smart PO systems can structure inputs and validate data, but over-rigid forms push employees to bypass the process. Balance matters more than control.

- Approvals need to be context-aware, not just hierarchical – intelligent workflows can skip redundant steps or fast-track urgent orders, reducing friction while maintaining governance.

- Supplier selection is becoming data-driven – integrated platforms and AI risk engines allow faster, more compliant vendor identification, but procurement judgment still overrides algorithms.

- Negotiation and award decisions remain a human+machine exercise – analytics provide leverage (scenario modeling, risk scoring), yet instincts and relationship knowledge often spot risks technology misses.

- Automation succeeds only with clean data and adoption – poor vendor master data, lack of integration, or weak change management can undermine even the best tools; the “smartness” depends on foundations.

Also read: Why Procurement in Manufacturing Still Runs on Emails: A Deep Dive into Manual Vendor Management?

Where the Mess Begins: The Requisition

Ask any category manager or procurement operations lead where bottlenecks arise, and you’ll hear the same thing: requisitions.

- They come in messy formats.

- They lack critical details—“Need IT equipment” without model numbers, for instance.

- They often bypass policy because employees are in a hurry.

There was a global engineering firm where 70% of requisitions required rework before they could even be processed. That meant lost days, sometimes weeks, before anything went out to suppliers.

Automation doesn’t magically clean this up. However, it can enforce structure at the point of entry. Smart forms that adapt based on category, AI-based text recognition pulling details from attachments, and rule engines that validate requests before submission—these reduce the “garbage in” problem dramatically.

The nuance: you don’t want to over-engineer. If forms become too rigid, employees circumvent them by emailing their favorite supplier directly. Balance is key.

Approval Workflows

Approval hierarchies are where automation has been around for decades, yet it’s still where deals stall. CFOs demand multiple layers of sign-off; department heads insist on visibility; compliance teams add controls.

A smart workflow doesn’t just route a requisition through an approval chain—it prioritizes based on context. For example:

- A recurring purchase under a contract might skip two levels of approval.

- Urgent maintenance orders could be flagged for immediate action even if the manager is on leave.

- Spend analytics can spot patterns: why do low-value POs in marketing always trigger four approvals, while IT gets a pass?

This isn’t just efficiency. It builds trust with business stakeholders, who start seeing procurement as a facilitator rather than a bureaucratic roadblock.

Supplier Discovery and Pre-Sourcing

Traditionally, once a requisition is approved, procurement scrambles to identify suppliers. In many organizations, that means dusting off Excel vendor lists or relying on whoever answered the phone last time.

Automation changes the calculus here:

- Vendor master data management tools can auto-suggest qualified suppliers.

- Integration with supplier networks (think SAP Ariba, Coupa, Jaggaer) means requisitions are instantly matched with vendors already vetted for compliance.

- AI-based supplier risk engines evaluate financial health, ESG performance, and even geopolitical exposure.

It sounds fancy, but in practice, it’s practical. A construction firm I worked with reduced onboarding time for niche suppliers (like local safety equipment vendors) from 30 days to 72 hours by plugging into a pre-vetted network. That’s not just faster—it prevents projects from stalling due to missing paperwork.

The Transition to RFQ/RFP

This is where “smart” earns its paycheck. Once a supplier pool is identified, requests for quotation (RFQ) or proposal (RFP) generation often bog down. Teams copy-paste from old documents, adjust specs manually, and send email chains that quickly spiral into chaos.

With intelligent PO processing:

- Templates become dynamic—automatically populating with requisition data, scope of work, and contract clauses.

- Pricing benchmarks feed into the RFQ so suppliers can’t wildly inflate bids.

- Communication is centralized; suppliers respond via portals rather than “reply all” email threads.

Still, don’t overpromise here. Even the slickest automation can’t eliminate the need for procurement judgment. Specs can be wrong, market conditions shift, and sometimes the cheapest bid really is a red flag.

Negotiation and Award: Human + Machine

Here’s where it gets tricky. Negotiation is often portrayed as a purely human skill—reading signals, building relationships, pushing back. Automation doesn’t replace that. What it does is provide leverage.

- AI can simulate different award scenarios (single-supplier vs. multi-supplier split) to highlight cost/risk trade-offs.

- Predictive analytics flag suppliers likely to default based on historical delivery performance.

- Dynamic dashboards let you compare not just price but total value: warranties, after-sales service, and delivery lead times.

Procurement leaders who ignore these tools are flying blind. At the same time, those who think the system will “decide” for them are equally misguided. The art is in blending data-backed insights with intuition. I’ve seen cases where the model recommended a low-cost supplier in Eastern Europe, but a category manager—based on years of market knowledge—knew political instability made it untenable. Both perspectives matter.

Contract Creation and Compliance

The leap from award decision to contract execution is another stumbling block. Manual drafting, redlines, and legal review can stretch weeks. Automation here looks different:

- Clause libraries that auto-insert standard terms based on category and jurisdiction.

- Version control to prevent ten conflicting drafts from floating around.

- E-signature integration to cut cycle time.

But the real win is in compliance monitoring. A PO isn’t “smart” if the terms get ignored. Automated matching of invoices against PO terms (three-way matching) is a classic example. More advanced setups track service-level adherence—was that delivery actually on time, did the vendor meet sustainability commitments, etc.

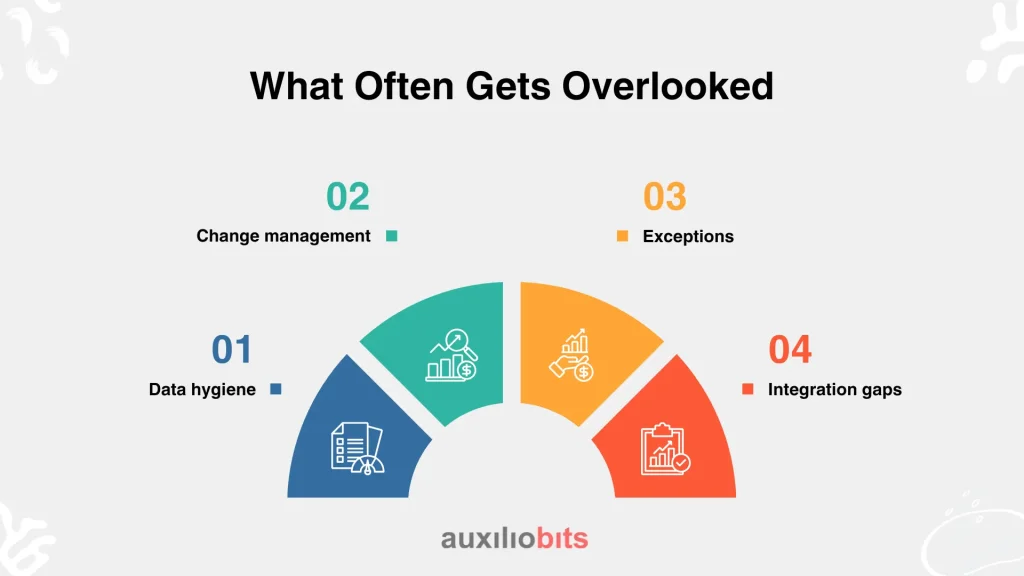

What Often Gets Overlooked

A few things automation advocates gloss over:

- Data hygiene—If your vendor master is outdated, automation simply accelerates bad outcomes. Garbage out, faster.

- Change management—Employees don’t like new systems. Without clear training and incentives, adoption falters.

- Exceptions—Procurement is full of one-off deals. Smart systems must allow graceful handling of edge cases.

- Integration gaps—Finance, ERP, and procurement platforms often don’t talk cleanly. Middleware or APIs solve some issues, but stitching them together is rarely seamless.

Ignoring these factors turns “smart” into a buzzword rather than a transformation.

Real-World Payoffs

When done right, smart PO processing delivers more than faster cycle times. Companies see:

- Cost reduction through competitive sourcing and elimination of maverick spending.

- Improved supplier relationships because vendors get clear, consistent communication.

- Audit readiness with digital trails of every approval, negotiation, and contract clause.

- Resilience by dynamically reallocating spending when a supplier falters.

Take a mid-sized pharmaceutical company. They slashed indirect procurement cycle time by 40% after implementing smart PO automation, but what impressed leadership most wasn’t speed. It was the ability to prove compliance to regulators during a surprise audit—with data pulled in minutes rather than days of rummaging through email archives.

Subtle Risks and Contradictions

Strangely, automation can sometimes weaken procurement’s credibility. When buyers lean too heavily on system recommendations, they risk losing their “commercial instinct.” Suppliers notice when negotiations feel scripted by software rather than driven by relationship acumen.

There’s also the danger of false confidence. An AI model may flag a supplier as low-risk based on financial metrics, yet miss cultural or ethical red flags that only surface through human engagement.

And then there’s the paradox: the more efficient requisition-to-award becomes, the more employees expect procurement to be invisible. That sounds good, but it risks marginalizing procurement’s strategic voice in the business.

The Road Ahead

Procurement leaders are right to chase automation, but the smarter path is selective investment rather than wholesale overhaul. Automate the drudgery—validations, document generation, supplier data pulls. Preserve the human space for negotiation, relationship management, and judgment calls.

A balanced ecosystem looks something like this:

- Machines handle validation, matching, document generation, and data crunching.

- Humans handle interpretation, supplier strategy, and nuanced decision-making.

- Shared space: award scenario analysis, risk modeling, continuous supplier performance review.

The organizations that get this balance right don’t just process POs faster—they reposition procurement as a partner in growth rather than a back-office cost center.