Key Takeaways

- AI-enabled logistics portals eliminate blind spots by aggregating and analyzing real-time data from GPS, IoT sensors, ERPs, and external feeds, transforming visibility from reactive to proactive.

- Predictive intelligence and machine learning empower supply chains to anticipate disruptions (like traffic, weather, or customs delays) and optimize routes, deliveries, and inventory in real-time.

- The benefits go beyond tracking—from enhanced customer satisfaction through proactive communication to significant cost savings via reduced errors, fuel use, and demurrage fees.

- Implementation success hinges on clean data, user adoption, and system integration. Enterprises must invest in change management, pilot programs, and vendor partnerships to maximize ROI.

- The future of logistics is hyper-connected and autonomous, combining AI with blockchain, IoT, and predictive maintenance to build a self-optimizing, resilient, and efficient supply chain.

In today’s global economy, the movement of goods is the lifeblood of commerce. From raw materials to finished products, every item embarks on a complex journey through the supply chain. For decades, this journey has been riddled with blind spots, delays, and a constant struggle for accurate information. Businesses have operated largely in the dark, reacting to problems rather than anticipating them. But what if you could see every single step, in real-time, with predictive insights at your fingertips? This isn’t a futuristic fantasy; it’s the present reality being shaped by AI-enabled logistics portals.

Also read: AI Strategy for Predictive Fleet Maintenance in Logistics.

The Opaque Reality: Why Traditional Logistics Falls Short

Before we dive into the transformative power of AI, let’s acknowledge the frustrations of traditional logistics. Imagine a vast, intricate network of roads, railways, oceans, and skies, all filled with your valuable cargo. Now imagine trying to track it using a patchwork of phone calls, faxes, fragmented spreadsheets, and outdated tracking numbers. This is the “black box” of conventional logistics.

1. Manual Processes: A Recipe for Delays and Errors

At the heart of the problem are manual processes. Data entry, communication between disparate systems, and the physical tracking of goods often rely on human intervention. This isn’t just slow; it’s prone to error. A single typo can send a shipment off course, a missed call can delay a critical delivery, and a handwritten manifest can become illegible. These small inefficiencies compound, leading to significant delays and escalating costs.

2. Disconnected Systems: The Information Silo Effect

Many organizations still operate with siloed information systems. Your Warehouse Management System (WMS) might not talk seamlessly with your Transportation Management System (TMS), and neither might it integrate perfectly with your Enterprise Resource Planning (ERP) software. This creates isolated pockets of data. A customer service representative might not have real-time access to a truck’s location, leading to frustrated customers and an inability to provide accurate updates. This lack of a unified data view means strategic decisions are often made based on incomplete or outdated information.

3. Reactive Problem Solving: Playing Catch-Up

When something goes wrong in a traditional supply chain – a truck breaks down, a port faces delays, or a customs issue arises – businesses are often caught off guard. They spend valuable time and resources scrambling to identify the problem, communicate with various parties, and devise a solution. This reactive approach is costly, damages customer relationships, and can significantly impact a company’s bottom line. You’re always playing catch-up, trying to mitigate damage rather than preventing it.

The cumulative effect of these challenges is a lack of supply chain transparency, higher operational costs, missed delivery windows, and ultimately, a compromised customer experience. Businesses know they need better visibility, but the sheer complexity of the global supply chain has historically made it an elusive goal.

Unveiling the Power: What Are AI-Enabled Logistics Portals?

AI-enabled logistics portals are game-changers for the entire supply chain ecosystem. These are not just advanced tracking systems; they are intelligent, centralized platforms that leverage the power of Artificial Intelligence to collect, analyze, and interpret vast amounts of logistics data in real-time. Think of them as the command center for your entire logistics operation, providing a single, unified, and intelligent view of every asset, shipment, and event.

How AI Transforms Data into Insights

The magic behind these portals lies in their ability to harness various AI technologies:

- Machine Learning (ML): This is the engine of predictive intelligence. ML algorithms analyze historical data patterns—past delivery times, weather conditions, traffic trends, and port congestion—to make incredibly accurate predictions. For instance, they can forecast an Estimated Time of Arrival (ETA) with far greater precision than traditional methods, even factoring in unforeseen variables. ML also powers anomaly detection, instantly flagging deviations from expected routes, speeds, or conditions, indicating potential issues before they escalate.

- Natural Language Processing (NLP): Logistics involves a lot of unstructured data – emails, customer service interactions, driver notes, social media posts about disruptions. NLP allows AI to understand and process this human language, extracting valuable insights. It can power intelligent chatbots within the portal for quick query resolution or analyze customer feedback to identify common pain points related to deliveries

- Predictive Analytics: This is where ML truly shines. By analyzing current and historical data, AI can predict potential disruptions, such as traffic jams, bad weather, or customs delays, days or even hours in advance. This allows logistics managers to proactively reroute shipments, adjust schedules, and comm

The Data Flow: From Source to Screen

The functionality of an AI-enabled portal relies on seamless data integration. It aggregates information from a multitude of sources:

- GPS and Telematics: Real-time location data from trucks, ships, and other vehicles.

- IoT Sensors: Data from sensors on cargo (temperature, humidity, shock), in warehouses (inventory levels), or on vehicles (fuel consumption, engine diagnostics).

- Enterprise Systems: Information from existing ERP, TMS, WMS, and CRM systems.

- External Data Feeds: Weather forecasts, traffic reports, port schedules, news alerts about geopolitical events, and even social media trends that could impact supply chains.

All this data flows into the AI-enabled portal, where it’s processed, analyzed, and presented through an intuitive dashboard, providing an unparalleled level of supply chain visibility.

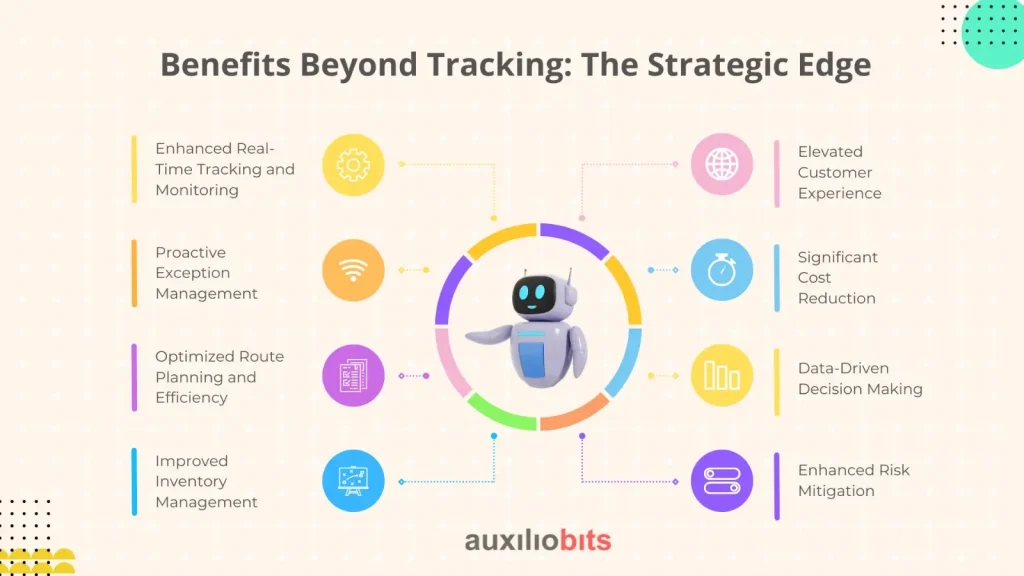

Benefits Beyond Tracking: The Strategic Edge

The advantages of adopting AI-enabled logistics portals extend far beyond simply knowing where a truck is. They unlock a cascade of benefits that impact every facet of your business, from operational efficiency to customer satisfaction.

1. Enhanced Real-Time Tracking and Monitoring

This is the foundational benefit. Unlike basic GPS, these portals offer hyper-accurate, real-time tracking of every shipment, asset, and even individual SKU. You can monitor conditions like temperature for perishable goods, track vibrations for fragile items, and know instantly if a container door is opened unexpectedly. This granular visibility provides unprecedented control and oversight.

2. Proactive Exception Management

This is where AI truly shines. Instead of reacting to problems after they occur, AI identifies potential exceptions before they become full-blown crises. If a shipment is likely to be delayed due to unforeseen traffic or a critical component isn’t going to arrive on time, the portal alerts you instantly. This enables proactive decision-making, allowing you to reroute, adjust schedules, or notify customers well in advance, minimizing disruption and costs.

3. Optimized Route Planning and Efficiency

AI algorithms constantly analyze traffic patterns, weather conditions, road closures, and delivery windows to suggest the most efficient routes in real-time. This dynamic re-routing capability not only reduces transit times but also optimizes fuel consumption and labor costs. For last-mile delivery, AI can bundle orders, sequence stops, and even account for driver breaks, significantly boosting delivery efficiency.

4. Improved Inventory Management

With real-time visibility into incoming shipments and outbound deliveries, businesses can achieve more precise inventory management. This means reducing the risk of costly stockouts, minimizing excess inventory (and associated warehousing costs), and optimizing inventory turns. AI can even predict demand fluctuations more accurately, leading to leaner, more responsive inventory levels.

5. Elevated Customer Experience

In today’s competitive market, informed customers are happy customers. AI-enabled portals allow you to provide accurate, real-time updates to your clients, from estimated delivery times to detailed tracking information. This transparency builds trust and reduces customer service inquiries, freeing up your team to handle more complex issues. Proactive communication about potential delays, along with revised ETAs, transforms a negative situation into a demonstration of excellent customer service.

6. Significant Cost Reduction

The cumulative effect of improved efficiency, reduced delays, optimized routes, and better inventory management is substantial cost reduction. Businesses save on fuel, labor, demurrage charges (fees for delayed loading/unloading), spoilage, and the costs associated with reactive problem-solving. AI helps identify hidden inefficiencies that can be eliminated, directly impacting the bottom line.

7. Data-Driven Decision Making

Every piece of data flowing through the portal becomes a valuable insight. Logistics managers can access comprehensive reports and analytics on performance metrics, carrier reliability, route efficiency, and more. This data-driven approach empowers strategic decision-making, allowing businesses to continually optimize their logistics operations, negotiate better contracts, and identify areas for long-term improvement.

8. Enhanced Risk Mitigation

By providing early warnings of potential disruptions, AI-enabled portals significantly enhance risk mitigation. Whether it’s a natural disaster, a port strike, or a vehicle breakdown, you have the information to respond quickly and strategically, minimizing the impact on your supply chain and business continuity.

Key Features of a Robust AI-Enabled Logistics Portal

To fully leverage these benefits, an AI-enabled logistics portal needs to be more than just intelligent; it needs to be practical, user-friendly, and highly functional. Here are some essential features to look for:

1. Intuitive User Interface (UI) and User Experience (UX)

Even the most powerful AI is useless if the interface is complex and difficult to navigate. A well-designed portal offers a clean, intuitive UI with easy-to-understand visualizations, maps, and dashboards. The user experience (UX) should be seamless, allowing users to quickly find the information they need without extensive training.

2. Customizable Dashboards

Different stakeholders need different views of the data. A robust portal allows for customizable dashboards tailored to specific roles – a dispatcher might need detailed real-time truck locations, while a supply chain manager might focus on overall performance metrics and predictive analytics.

3. Real-Time Alerts and Notifications

Critical information needs to be delivered instantly. The portal should provide configurable real-time alerts and notifications via SMS, email, or in-app messages for any deviation from the plan – delays, unexpected stops, temperature excursions, or delivery confirmations.

4. Seamless Integration Capabilities

A truly effective portal doesn’t replace your existing systems; it enhances them. It must offer robust integration capabilities with your current ERP, TMS, WMS, CRM, and other third-party logistics (3PL) systems to ensure a unified flow of information and avoid data silos.

5. Comprehensive Reporting and Analytics

Beyond real-time tracking, the portal should offer powerful reporting and analytics tools. This includes historical data analysis, performance benchmarks, carrier scorecards, cost analysis, and custom report generation, providing actionable insights for continuous improvement.

6. Collaborative Tools

Logistics is a team effort. The portal should facilitate seamless communication and collaboration among all stakeholders – drivers, dispatchers, warehouse staff, customer service, and even external partners like carriers and customers. This could include in-app messaging, document sharing, and shared task management.

7. Scalability and Security

As your business grows, your logistics needs will too. The portal must be scalable to handle increasing data volumes and users without performance degradation. Equally critical is robust security, protecting sensitive business and customer data with advanced encryption and access controls.

Implementing AI-Enabled Portals: Navigating the Journey

Adopting a new technology, especially one as transformative as an AI-enabled portal, requires careful planning. While the benefits are immense, businesses often face common challenges during implementation.

1. Data Quality and Integration: The Foundation

The success of any AI system hinges on the quality of its data. Poor data quality – incomplete, inaccurate, or inconsistent information – can lead to flawed predictions and unreliable insights. A significant effort needs to be made in data cleansing and standardization before implementation. Furthermore, integrating the new portal with legacy systems can be complex, requiring robust APIs and potentially middleware solutions to ensure seamless data flow.

2. Change Management: Embracing the New

Introducing a new system means changing established workflows and processes. Change management is crucial. Employees need to understand why the new system is being implemented, how it will benefit them, and receive adequate training. Without proper buy-in and training, even the most sophisticated technology can fail to deliver its full potential.

3. Choosing the Right Vendor: A Strategic Decision

The market for logistics technology is expanding rapidly. Choosing the right vendor is a critical strategic decision. Look for providers with a proven track record, industry-specific expertise, a scalable and secure platform, excellent customer support, and a clear roadmap for future development. Don’t just focus on features; assess their ability to be a long-term partner in your logistics journey.

4. Phased Implementation and Employee Training

A phased implementation approach is often more effective than a “big bang” rollout. Start with a pilot program in a specific region or for a particular type of shipment to iron out kinks and gather feedback. Comprehensive employee training is non-negotiable. Ensure that all users, from warehouse staff to senior management, are proficient in using the portal’s features relevant to their roles.

The Future of Logistics: Hyper-Visibility and Beyond

The current capabilities of AI-enabled logistics portals are just the beginning. The future promises even more interconnected, intelligent, and autonomous supply chains.

- Blockchain Integration: Combining AI-enabled portals with blockchain technology will create unparalleled levels of trust and traceability. Every transaction and movement could be immutably recorded, providing irrefutable proof of origin, condition, and delivery, eliminating disputes and enhancing transparency across the entire chain.

- IoT Expansion: The proliferation of sophisticated IoT sensors will provide an even richer tapestry of real-time data. Imagine sensors on individual products, communicating directly with the portal about their journey, environmental conditions, and even potential damage.

- Autonomous Logistics: As autonomous vehicles (trucks, drones, robots) become more commonplace, AI-enabled portals will evolve to manage and orchestrate these self-driving fleets, optimizing their movements, maintenance, and interactions with human-operated elements of the supply chain.

- Predictive Maintenance: AI will increasingly monitor the health of logistics assets – trucks, forklifts, shipping containers – predicting when maintenance is required before a breakdown occurs. This will minimize costly downtime and improve asset utilization.

The journey towards hyper-visibility is well underway. Logistics operations will become truly self-optimizing, adapting to changing conditions in real-time, predicting and mitigating risks, and delivering unparalleled efficiency and customer satisfaction.

Conclusion

The days of operating with limited visibility in logistics are rapidly drawing to a close. Real-time logistics visibility using AI-enabled portals is no longer a luxury; it’s a strategic imperative for businesses aiming to thrive in the modern global economy. These intelligent platforms empower companies to move from reactive problem-solving to proactive optimization, transforming supply chain challenges into competitive advantages.

By embracing AI, businesses can achieve unprecedented levels of efficiency, dramatically reduce costs, enhance customer experiences, and build a more resilient and responsive supply chain. The investment in these cutting-edge solutions isn’t just about tracking; it’s about unlocking a new era of logistics excellence, paving the way for smarter decisions and a more predictable, profitable future.

Are you ready to transform your logistics operations and step into this new era of real-time visibility? The future of your supply chain is waiting.