Key Takeaways

- Coordination—not drones or trucks alone—is the real competitive lever in last-mile delivery. Success depends on real-time orchestration between drones, drivers, micro-hubs, and dispatch systems.

- Drones add complexity before they add efficiency. Weather, payload limits, regulatory ceilings, and spillover management force constant human and AI-led decision-making.

- Drivers are not being replaced—they’re becoming strategic assets. Their ability to handle exceptions, reroute, and manage customers fills the reliability gaps that drones can’t bridge.

- Fulfillment centers are the control tower of last-mile operations. Channel activation—from drones to bikes to vans—begins with how micro-fulfillment and staging decisions are made upstream.

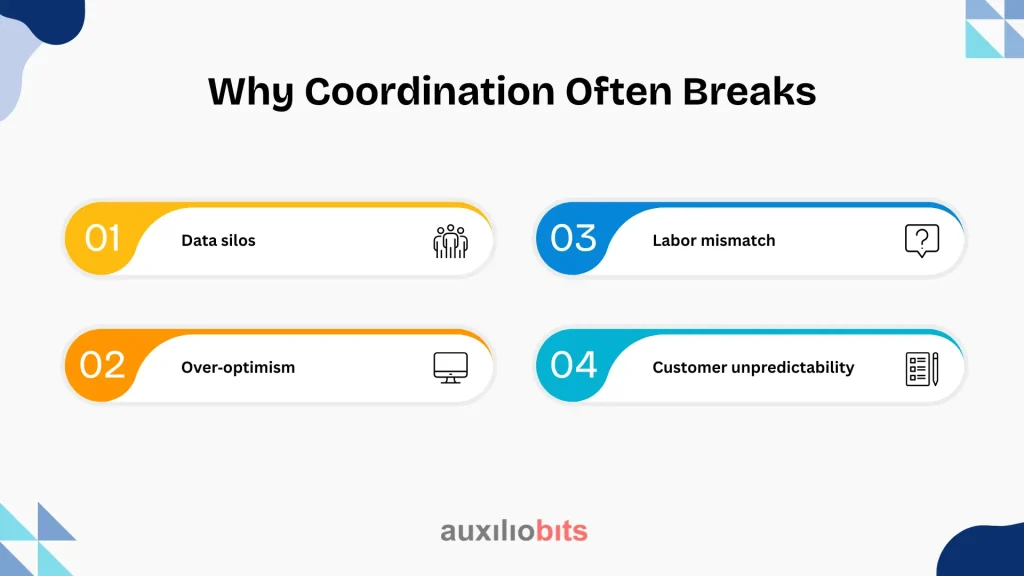

- Coordination often fails due to human and system misalignment, not lack of innovation. Data silos, mismatched staffing, unrealistic promises, and KPI conflicts break orchestration more than hardware limitations.

A few years ago, the idea of drones buzzing overhead with packages strapped to their belly seemed, at best, gimmicky. Today, some fulfillment networks are putting them into actual schedules alongside vans, bikes, autonomous carts, and human couriers. And here’s where it gets interesting: none of these channels exists in isolation. The glue—what logistics managers are now obsessing over—is the orchestration happening at the very last leg of the supply chain.

The term “last‑mile” has always been somewhat misleading; the challenge is rarely about distance alone. It’s about variability, density, and real‑time decision-making. The agent—whether that’s a dispatching algorithm, a field supervisor, or increasingly a hybrid of human plus software—must knit together drones, drivers, and fulfillment nodes in ways that balance speed with cost, convenience with safety, and experimentation with scale.

Also read: Dynamic shipment consolidation using agentic decision logic

The Shift from Linear to Layered Last-Mile

For the past two decades, last‑mile operations ran on fairly linear assumptions. Packages were left at distribution centers in trucks, drivers followed optimized routes, and delivery timing depended on network density. Efficiency boiled down to consolidation.

That model is cracking in multiple places.

- Urban congestion makes traditional van routes unpredictable daily.

- Suburban spread dilutes density, raising per-drop costs.

- Customer tolerance for “delivery tomorrow” has eroded in many product categories; groceries and pharmacies demand two‑hour windows.

- Sustainability pressures force companies to experiment with lower‑emission or zero‑emission modalities.

As a result, the last‑mile playbook is expanding. Drones serve high-priority, lightweight, short-distance payloads. E‑cargo bikes handle dense downtown zones. Vans and trucks remain the workhorses for consolidated volume. Fulfillment centers, both micro and regional, act as staging points. The old model of coordination (route planning once at night, execution during the day) no longer cuts it. Managers need dynamic orchestration.

The Role of the “Coordinator”

In practice, coordination is distributed across:

- Dispatching platforms that ingest real‑time data.

- Floor supervisors in fulfillment centers are triaging urgent orders.

- Drivers themselves, who make choices on shortcuts or customer contact.

- Customer-facing apps nudging recipients to pick lockers or reschedule time windows.

These agents, digital and human, collectively decide: Which package moves by drone? Which stays in the van? When is it cheaper to drop something at a nearby locker rather than attempt a home delivery at 7 pm?

Here’s an example worth considering. In 2023, Walmart announced drone delivery partnerships covering select U.S. suburbs. While customers saw novelty (watching goods descend from above), operations teams were juggling far trickier processes: drones couldn’t handle heavy orders, weather grounded half the fleet on some days, and FAA rules limited flight zones. Dispatchers had to decide on the fly whether to divert those orders to ground couriers without missing promised windows. Coordination wasn’t just about physics or hardware—it was about customer expectation management.

When Drones Complicate Instead of Simplify

Several logistics directors are as much an operational headache as they are a branding coup. The reasons:

- Payload restrictions: Even advanced drone fleets barely cover 5–8 pounds reliably. Try fitting that into pharmacy or grocery replenishment.

- Regulatory ceilings: Beyond-visual-line-of-sight approval is rare. That forces shorter range or line-of-sight stations, which complicates hub mapping.

- Weather disruptions: Unlike vans, drones can’t “wing it” in bad weather. A summer thunderstorm can freeze 20% of capacity instantly.

So coordination teams have to constantly simulate scenarios: If a batch of drones is grounded, which vans have slack capacity to absorb the spillover? Do you proactively hold back assignments until the weather clears, or promise delivery by another channel outright?

This kind of contingency planning rarely gets airtime in CEO keynotes. But on the ground, it’s what separates token drone pilots from serious integration.

Drivers Still Hold Strategic Value

Despite headlines, human drivers remain the backbone of the last‑mile. Their resilience isn’t just about carrying heavier payloads. It’s about situational flexibility.

- A driver can negotiate a blocked street by running a package on foot.

- They can troubleshoot customer absence, rerouting to neighbors or parcel shops.

- They manage exceptions (damaged packages, address errors, live customer complaints) that algorithms still fumble.

For this reason, “coordinating” drones and drivers isn’t a zero‑sum game. Smart networks treat drones as supplements, not replacements. A drone may peel off urgent deliveries or rural addresses where density is too low to justify a dedicated route. But consolidation still favors the van.

Amazon’s own experience is telling. Prime Air drones made headlines, yet the biggest reliability gains in their last‑mile division came from routing software that improved driver load balancing. No flashy hardware, just better assignment logic.

The Pivotal Role of Fulfillment Centers

Too often, discussions on the last‑mile focus only on the handoff between the courier and the doorstep. In reality, the node that controls the tempo is the fulfillment center or micro‑hub. These facilities ration the work: which items are picked for drone dispatch vs. slapped onto bulk vans; whether fresh items merit cross‑docking into e‑cargo bike fleets; how many drivers are released for evening shifts.

- A dense urban micro‑hub may stage 200 packages for staggered drone dispatches within a 5‑mile radius.

- A suburban warehouse may combine standard e‑com parcels into pool routes, with only outliers diverted to drones.

- Experiments show refrigerated lockers tied directly to fulfillment hubs reduce missed grocery deliveries by cutting out drivers altogether.

The point is: scenes of drones landing in backyards make good video, but it’s the fulfillment planner who decides in the morning whether drones light up at all.

Real-World Case Nuances

A couple of grounded examples:

- Zipline in Rwanda: Medical supply drones work only because the fulfillment process was tailored to them. Packages are pre‑packed in special dispensers, release is automated, and customer expectation is consistent: supplies drop at regional hospitals, not doorsteps. Notice how different this is from the consumer use case—no fragile vases, no need for flexible ETA windows.

- Starship autonomous carts in U.S. campuses: They function because the fulfillment centers are essentially cafeteria kitchens. Routing is simple (sidewalks, not highways). Coordination is easier—when carts stall, a remote supervisor steps in.

- Ocado in the U.K.: Instead of drones, they focused on fulfillment robotics at their distribution centers, making van truckloads hyper‑dense and more punctual. A reminder: the glamour of drones can sometimes distract from gains sitting upstream.

These illustrate a sobering truth: technology must fit into the ecosystem, not the other way around.

Why Coordination Often Breaks

Even technologically mature retailers run into breakdowns. Some recurring culprits:

- Data silos: Real‑time weather feeds exist, but don’t always integrate into dispatch modules. Drones get scheduled only to be canceled minutes later.

- Over‑optimism: Marketing teams promise instant drone delivery everywhere, forcing field agents to patch over impossible cases.

- Labor mismatch: If a fulfillment center hasn’t staffed appropriately, drone sortation (which often needs specialized prep) simply doesn’t happen.

- Customer unpredictability: Failed home deliveries eat away the margin drones were supposed to save.

What’s often discussed in conferences is the technology curve. What isn’t discussed enough is human error, cross‑team misalignment, and competing KPIs among fulfillment, transportation, and marketing.

Toward a More Mature Coordination Model

If the goal is not just hype but scalable, sustainable last‑mile networks, coordination has to evolve in several pragmatic ways:

- Dynamic decisioning engines: Move away from static route planning. Agents—whether AI-based or human—should be able to reassign loads mid‑shift.

- Shared labor pools: Don’t pigeonhole workers into drone‑dispatch or van‑dispatch teams. Create cross‑training to smooth peaks.

- Customer-facing flexibility: Give end-customers nudges toward lockers, pickup points, or slightly altered time windows. A five‑minute delay promises results in an hour of gain in reliability.

- Incremental drone scaling: Too many networks go “all‑in” or “not at all.” Mature models treat drones as variable capacity—activated only under certain density profiles.

The industry underestimates the cultural component. For years, drivers in parcel networks were treated as replaceable cogs. Now, those same networks need drivers to manage the shortcomings of drones, temper the promises made by marketing, and keep customers from defecting. A little more respect and investment in human judgment might solve more problems than adding another fleet of quadcopters.

A Contradiction Worth Exploring

The irony here is hard to ignore. Logistics leaders talk about automation, autonomy, and “taking humans out of the loop.” Yet the most successful experiments—whether Zipline or campus delivery bots—involve putting humans back into the loop at the right choke points. Supervisors monitoring drone fleets, dispatchers making judgment calls, fulfillment workers prepping SKU-specific parcels: they are the thin line between novelty and meaningful reliability.

So perhaps the question isn’t, “When will drones and robots take over the last‑mile? Perhaps it should be: When will coordination frameworks mature enough to let every channel—human or machine—play to its strength without dragging the rest of the network down?

Until then, last‑mile agents remain conductors in an orchestra where half the instruments are still learning to play. Some days, the symphony works. Other days, it’s just noise. And that’s the reality logistics professionals actually face when someone in a boardroom says, “We’ll just add drones.”