Key Takeaways

- Marry brains with hands: Fusion of ML and RPA is the bedrock of Manufacturing Automation.

- Start small, scale fast: A single, well‑chosen pilot pays dividends and funds further expansion.

- Think architecture‑first: Event‑driven, observable patterns beat quick‑and‑dirty scripts every time.

- Measure relentlessly: KPIs validate progress and expose optimisation headroom.

- Prepare for agents: Cognitive factories are coming; the groundwork you lay today determines competitive advantage tomorrow.

Global competition, volatile supply chains, and spiralling energy costs are squeezing margins across every subsector—from precision electronics to heavy machinery. Traditional lean initiatives and mechanical robotics have already wrung out most obvious savings, yet Manufacturing Automation still suffers from three silent killers:

- Hidden downtime caused by undiagnosed equipment wear

- Quality drift that escapes sample‑based inspection until rework explodes

- Administrative drag as planners, schedulers, and buyers fight with legacy screens.

An intelligent automation layer that merges robotic process automation (RPA) with machine‑learning (ML) models tackles all three. Bots clear repetitive clicks while models provide real‑time judgment, converting raw data into adaptive actions. Early adopters report:

- Up to 40 % shorter change‑over windows

- Scrap reductions approaching 30 % year‑over‑year

- Purchase‑order cycle times cut from days to minutes

These numbers are not science fiction; they result from stitching cognitive insight into otherwise deterministic digital threads and placing that capability directly on the shop floor.

Also read: Leveraging Generative AI for Predictive Maintenance in Manufacturing Equipment

RPA + ML: A Quick Refresher

Before diving deeper, align on terminology:

| Concept | What it is | Common Tools | Role in Manufacturing Automation |

| RPA | Software that replicates human UI actions—clicks, keystrokes, file moves | UiPath, Power Automate, Automation Anywhere | Automates rule‑based steps in ERP, MES, PLM, and email clients |

| ML | Algorithms that learn patterns from historical data and emit probabilistic predictions | TensorFlow, PyTorch, Vertex AI, Azure ML Studio | Detect defects, forecast demand, and predict failure |

| Intelligent Automation | The tight coupling of RPA for orchestration and ML for cognition | Composite platforms or best‑of‑breed mashups | Drives closed‑loop, self‑optimising workflows |

Think of RPA as the hands, ML as the brain, and connectivity as the nervous system of a digital factory. Used together, they exceed the sum of their parts, moving Manufacturing Automation beyond brute repetition toward continuous adaptation.

In many factories, RPA bots live on virtual machines while ML inference runs on containerised microservices. Establishing a secure, low‑latency bridge between the two is crucial. Use gRPC or REST with mutual TLS, and cache predictions locally so bots never stall if the network jitters. Finally, align logging schemas so that bot actions and model inputs can be correlated during root‑cause analysis. This single habit slashes troubleshooting time by half and demystifies AI for line engineers.

Where Plain RPA Falls Short on the Shop Floor?

RPA excels at deterministic tasks, but real production is messy. Consider these limitations:

- Visual ambiguity – RPA cannot tell a minor scratch from a fatal crack on an anodised surface.

- Data volatility – Sensor readings wander; fixed rules struggle to separate harmless noise from actionable signal.

- Decision complexity – BOM substitutions, tolerance ranges, and regulatory nuances create branch logic that quickly explodes beyond maintainable script length.

- Scalability ceilings – A fleet of unattended bots can execute steps, yet someone still triages exceptions, validates outcomes, and tweaks parameters.

Each gap maps neatly to an ML capability—vision, anomaly detection, classification, optimisation—illustrating why Manufacturing Automation stays incomplete until the two technologies converge.

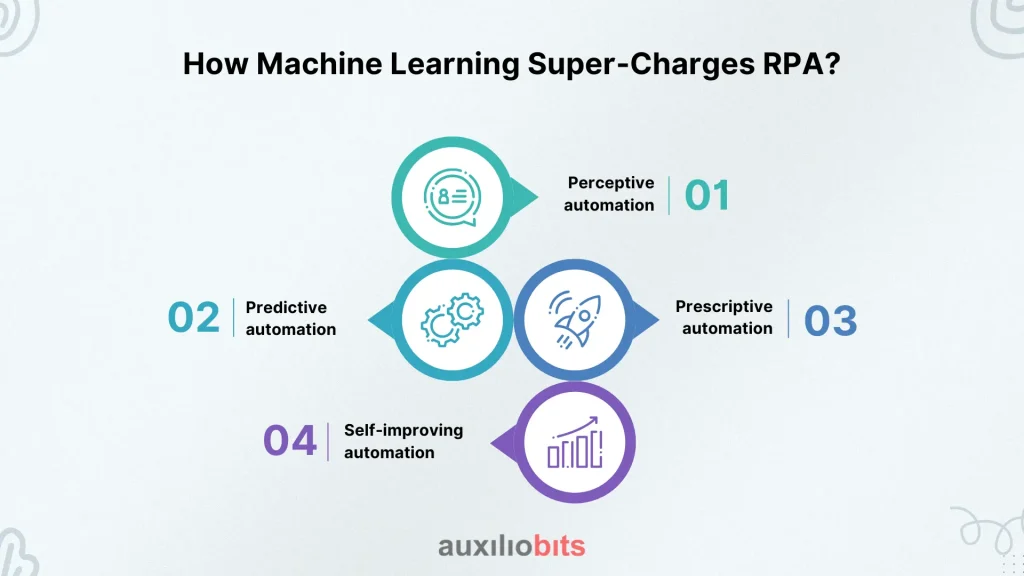

How Machine Learning Super‑Charges RPA?

When ML modules feed predictions into bot logic, four transformational behaviours emerge:

- Perceptive automation – Computer vision models examine every unit, feed pass/fail status to bots that route good parts forward and bad parts to rework without human eyes.

- Predictive automation – Time‑series models forecast bearing fatigue; bots create preventive maintenance work orders, secure parts, and schedule downtime automatically.

- Prescriptive automation – Reinforcement‑learning agents suggest the optimal machine settings for today’s material lot; bots program PLCs accordingly.

- Self‑improving automation – Feedback loops capture operator overrides, retrain the model nightly, and redeploy refreshed weights, so tomorrow’s decisions are better than today’s.

By embedding these behaviours, factories transform individual automation islands into a holistic, intelligent fabric where every byte of data yields a measurable, bottom‑line outcome.

Six High‑Impact Use Cases

These six real-world use cases show how combining ML with RPA unlocks high-impact gains in Manufacturing Automation.

1. Inline Visual Quality Inspection

- Technology mix: Edge GPU, convolutional neural network (CNN) classifier, UiPath robot

- Flow: Camera image → ML defect probability → bot decides to accept or divert → MES updated.

- Benefit: Removes manual inspection bottleneck; improves First Pass Yield, a key Manufacturing Automation metric.

2. Predictive Maintenance Ticketing

- Technology mix: LSTM vibration model, alert threshold service, Power Automate flow

- Flow: Sensor vibration → model predicts failure in 48 h → bot opens maintenance ticket → parts auto‑ordered

- Benefit: Converts reactive downtime into planned micro‑stoppages, raising Overall Equipment Effectiveness.

3. Demand‑Driven Production Scheduling

- Technology mix: Gradient‑boosting demand forecaster, RPA scheduler bot

- Flow: ERP sales history → forecast by SKU → bot revises production plan every four hours

- Benefit: Shrinks inventory buffers, elevating cash flow while maintaining service levels.

4. Supplier Invoice Reconciliation

- Technology mix: OCR with transformer‑based key‑value extraction, bot validator

- Flow: PDF invoice → extracted fields → bot cross‑checks PO in SAP → discrepancies flagged

- Benefit: Eighty percent reduction in finance touch‑time; early‑pay discounts captured automatically.

5. Energy‑Peak Shaving

- Technology mix: Short‑horizon load forecaster, RPA action bot

- Flow: Real‑time meter data → predict next tariff spike → bot pauses non‑critical ovens → alerts supervisor

- Benefit: Single‑digit percentage energy savings translate into six‑figure annual cost avoidance.

6. Zero‑Defect Traceability

- Technology mix: Statistical process control model, bot for containment actions

- Flow: Process variables deviate → anomaly alert → bot quarantines batch and updates digital ledger

- Benefit: Regulatory compliance and customer satisfaction through transparent, automated recalls if needed.

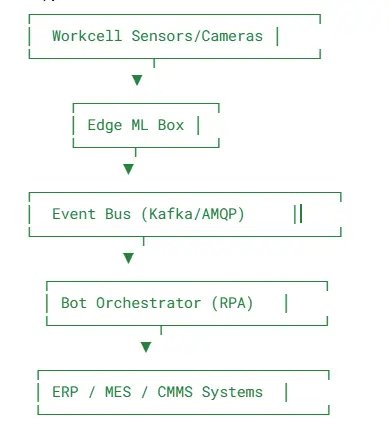

Reference Architecture Blueprint

A robust architecture keeps cognition, orchestration, and control loosely coupled yet tightly aligned.

java

CopyEdit

Design principles:

- Edge‑to‑cloud continuum – Keep high‑frequency inference at the edge; push heavy retraining to the cloud.

- Event‑driven – Use a message backbone so that neither bots nor models block each other.

- Observability first – Central dashboards track bot success rates and model accuracy side by side, allowing joint root‑cause analysis.

Edge Pattern Spotlight: Small‑form‑factor industrial PCs with integrated GPUs, such as NVIDIA Jetson modules, now cost less than a quality torque wrench. Deploying a twin at every critical workstation turns cameras and force sensors into mini data centres, pushing latency below 60 ms. This speed is often the difference between catching a defect and shipping it downstream undetected.

Legal Note: Upcoming EU AI Act demands audit trails and human veto rights for safety‑critical AI; bake compliance into every architecture design.

Implementation Roadmap

Successful programs follow a staged journey:

Discovery (Weeks 0–4)

- Map current workflows, exception rates, and latency pain points.

- Perform data availability and quality assessment; poor data torpedoes ML ambitions.

Pilot (Weeks 5–12)

- Select one high‑value, low‑dependency process, often visual inspection or invoice matching.

- Build a minimal‑viable pipeline; measure baseline vs. automated performance.

Stabilise (Weeks 13–20)

- Add monitoring, rollback paths, and retraining automation.

- Formalise change management playbooks so operators trust system outputs.

Scale (Months 6–18)

- Create a component catalogue: reusable connectors, common data schemas, and security standards.

- Roll out to parallel lines, related plants, and upstream suppliers.

Optimise (Ongoing)

- Launch continuous‑improvement sprints; mine bot logs for new ML feature ideas.

- Transition ownership to a dedicated Manufacturing Automation Centre of Excellence.

Cultural Dimension: Change management is not an afterthought. Run “bot ambassador” programs where enthusiastic operators get early exposure to prototypes, name the bots, and share success stories over internal social channels. Such rituals humanise the technology, flip resistance into pride, and create a viral pull for further Manufacturing Automation projects across departments.

Measuring Success: KPIs & ROI

Numbers silence sceptics. Track three tiers:

- Operational – First Pass Yield, Mean Time Between Failure, schedule adherence.

- Financial – Cost per unit, inventory‑turn ratio, energy cost per hour.

- Experiential – Operator satisfaction, exception‑handling time, engineering workload reduction.

Tip: Present ROI in payback months, a language the finance office loves. Many pilots recoup investment within 9–12 months through scrap avoidance alone.

Advanced Analytics Layer: Once primary KPIs stabilise, layer multivariate control charts and causal‑impact models on top of raw metrics. These advanced dashboards pinpoint which specific model version or bot update moved the needle, turning performance reviews from subjective debates into data‑driven retrospectives that continuously sharpen competitive edge.

Common Pitfalls & How to Avoid Them

| Pitfall | Consequence | Preventive Tactic |

| Training on biased or outdated data | Model hallucinations, false alarms | Institute quarterly data‑drift audits |

| Bots are treated as one‑off scripts | Fragile “spaghetti automation” | Enforce CI/CD pipelines and version control |

| Ignoring cybersecurity | Exposed credentials, plant downtime | Apply zero‑trust principles and rotate secrets |

| Over‑promising timelines | Stakeholder fatigue | Conduct scope triage and publish realistic burn‑down charts |

Addressing these proactively preserves momentum and protects the credibility of your Manufacturing Automation vision.

Recovery Playbook: Even the smartest stack will one day stumble. Draft and rehearse incident‑response runbooks that cover model rollback, bot failover, and manual override switches at the machine level. Clear responsibility matrices ensure downtime is minutes, not hours, safeguarding both revenue and brand reputation.

The Road Ahead: Toward Agentic Factories

The next frontier is Agentic Process Automation (APA), where autonomous agents negotiate, plan, and execute entire production objectives without human orchestration. Picture an agent that:

- Reads demand signals from e‑commerce APIs

- Simulates production capacity under current labour and energy constraints

- Contracts flexible manufacturing partners when bottlenecks emerge

- Commissions RPA bots and ML models as microservices on demand

Agents turn today’s dashboards into tomorrow’s command centres—factories that reason, not react. Early sandbox deployments hint at double‑digit agility gains and a dramatic reduction in planner workload.

Sustainability Angle: Pair predictive maintenance with carbon‑intensity APIs so agents shift energy‑hungry processes to green grid windows, cutting Scope 2 emissions without capital spend.