Key Takeaways

- Automating warehouse tasks like picking, packing, and shipping significantly boosts speed and accuracy, helping businesses meet rising customer expectations and effortlessly manage high volumes.

- Seamless integration of systems like WMS, ERP, TMS, and robotics via a Warehouse Execution System (WES) ensures real-time synchronization and optimized warehouse operations from start to finish.

- Technologies such as RFID, computer vision, and AI minimize human errors and provide real-time visibility into inventory, enhancing operational reliability and customer satisfaction.

- Automation enables warehouses to handle seasonal demand spikes and business growth by scaling systems and robots without significant workforce or infrastructure increases.

- While automation offers substantial benefits, businesses must address high upfront costs, integration complexity, workforce adaptation, and cybersecurity risks through careful planning and change management.

In today’s fast-paced supply chain world, efficiency is key. Warehouses are no longer just places to store goods—they’ve become smart, high-tech centers that help speed up operations, improve accuracy, and reduce costs. A big part of this change is warehouse task automation, which helps manage everything from receiving goods to shipping them out.

In this blog, we’ll explore how automation is reshaping warehouse workflows, the technologies enabling this transformation, and a step-by-step walkthrough of how automation powers each stage of warehouse operations.

Also read: Secure AI Agent Development for Protected Health Information Processing

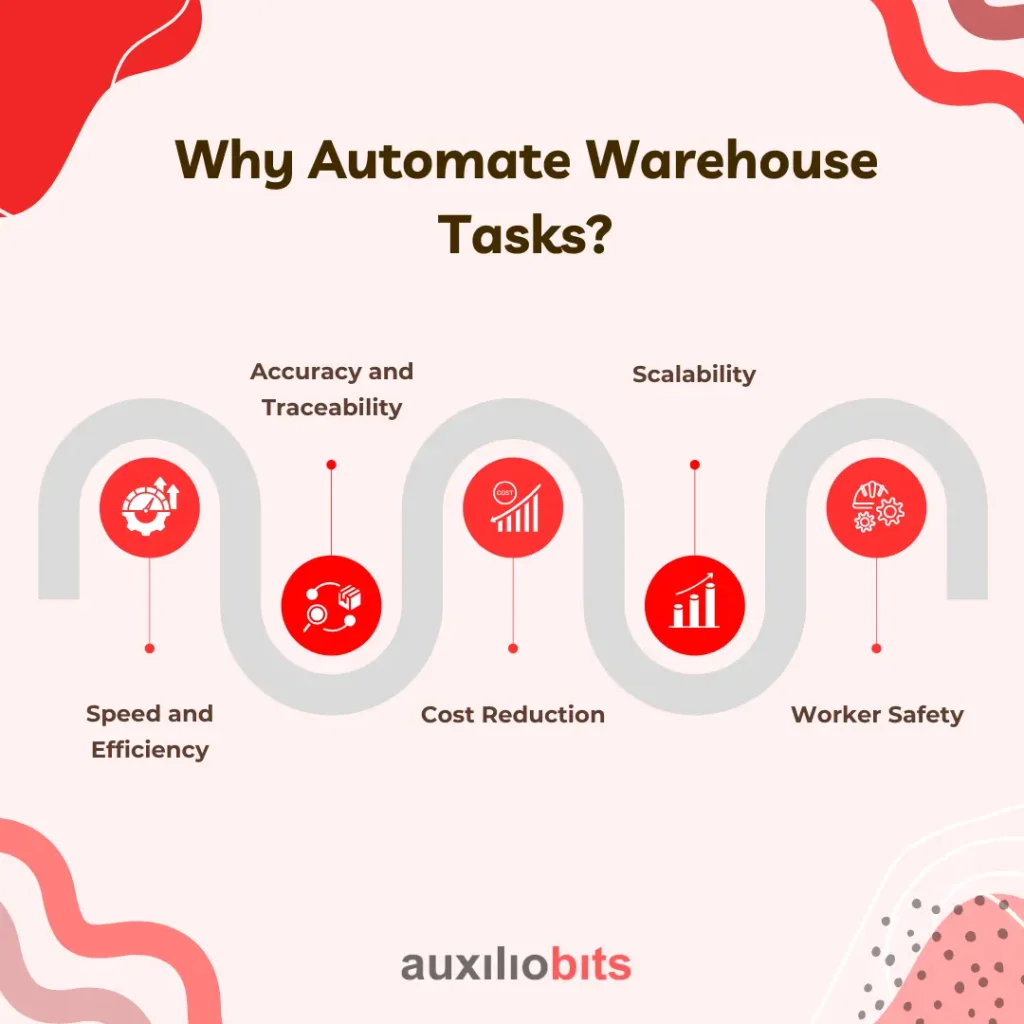

Why Automate Warehouse Tasks?

In today’s world, where customers expect faster deliveries and businesses face tough competition, warehouse automation has become more critical than ever. But what does automating warehouse tasks mean, and why should companies care? Simply put, warehouse automation uses technology to perform tasks that were once done by hand. This includes sorting, picking, packing, moving, and tracking goods. Let’s explore why automating these tasks makes a big difference.

1. Speed and Efficiency:

One of the biggest reasons for warehouse automation is to make things faster and more efficient. Many warehouse tasks, like scanning items, moving boxes, or putting goods on shelves, are repetitive. These tasks take time and can tire out human workers. Automation tools like conveyor belts, robotic arms, and software systems can perform these tasks much faster and without taking breaks.

For example, a robot can sort hundreds of packages in a few minutes, which would take several workers much longer. This means businesses can process more orders in less time, keeping up with high demand and improving customer satisfaction.

2. Accuracy and Traceability:

Mistakes in a warehouse can be costly. If the wrong item is packed or shipped to a customer, it causes delays and extra costs. That’s why accuracy is so important. Automated systems reduce human errors. Barcode scanners, RFID tags, and AI-powered cameras help track items at every step.

These technologies ensure the right product is picked, packed, and sent to the right customer. They also make it easy to trace where an item is at any time. This is helpful not just for tracking deliveries but also for solving problems if something goes wrong.

3. Cost Reduction:

Although setting up automation might require an investment, it saves money in the long run. When machines handle routine tasks, companies need fewer workers for those jobs. This doesn’t mean people are replaced, but rather that their time is used better on tasks that require decision-making, problem-solving, or personal attention.

Automation also helps make better use of space. For example, automated storage systems can fit more items in the same area by stacking things more tightly and organizing them smartly. This means businesses can store more goods without needing to expand their warehouse.

4. Scalability:

As a business grows, so does the number of orders and items handled. During busy seasons like holidays, demand can go up quickly. Hiring and training new workers for just a few months is not always easy or affordable, but automation systems can be scaled up more easily.

For instance, more robots or automated lines can be added, and software can be updated or expanded to handle more data. This flexibility helps businesses grow without worrying about hiring or training new staff.

5. Worker Safety:

Some warehouse tasks, like lifting heavy items, working in high places, or handling hazardous materials, can be dangerous. Automation can take over these high-risk jobs, making the workplace safer for everyone.

Robots can lift heavy loads, drones can check high shelves, and automated vehicles can move pallets around the warehouse. This reduces the chance of injuries and helps workers stay healthy and productive.

Warehouse automation is about using cool new technology and solving real problems. It makes warehouses faster, more accurate, and more cost-effective while keeping workers safer and helping businesses grow. As supply chains become more complex, automation is quickly becoming a must-have for companies that want to stay competitive.

Core Warehouse Tasks and Automation Technologies

Let’s examine how automation enhances each phase of warehouse operations.

1. Inbound Tracking and Goods Receiving

Key Tasks:

- Verifying incoming shipments

- Unloading trucks

- Checking goods against purchase orders

- Routing items to appropriate storage

Automation Technologies:

- RFID Scanners: Instantly read tags as goods arrive.

- Automated Dock Management: AI systems schedule dock use and manage dock door availability.

- Computer Vision Systems: Verify product quantity and condition during unloading.

- Mobile Robots (AMRs): Transport goods from the dock to sorting zones or storage.

Benefits:

- Faster and more accurate receiving

- Real-time inventory updates

- Reduced congestion at the docks

2. Putaway and Storage

Key Tasks:

- Assigning storage locations

- Transporting items to the shelves

- Logging item locations

Automation Technologies:

- Warehouse Management Systems: Use AI to recommend optimal storage locations.

- Automated Guided Vehicles (AGVs) and AMRs: Handle the transport of goods to assigned locations.

- Innovative Shelving Systems: Adjust automatically to product size and weight.

Benefits:

- Maximized storage density

- Faster retrieval

- Reduced search time and misplacement

3. Inventory Management and Cycle Counting

Key Tasks:

- Tracking stock levels

- Conducting regular cycle counts

- Identifying stock discrepancies

Automation Technologies:

- Drones with RFID Readers: Fly through aisles to perform cycle counts.

- IoT-Enabled Shelves: Report stock levels in real time.

- AI Inventory Forecasting: Predict demand and optimize reorder points.

Benefits:

- Real-time inventory visibility

- Elimination of stockouts or overstocking

- Minimal human intervention

4. Order Picking and Consolidation

Key Tasks:

- Locating items for customer orders

- Consolidating items into single shipments

- Verifying order accuracy

Automation Technologies:

- Pick-to-Light and Voice Picking Systems: Guide workers efficiently.

- Robotic Picking Arms: Select and place items into totes or conveyors.

- AI Path Optimization: Reduce travel time for pickers or robots.

Benefits:

- Faster fulfillment cycles

- Reduced picking errors

- Lower labor dependency

5. Packing and Labeling

Key Tasks:

- Packaging goods securely

- Printing shipping labels

- Attaching the correct documentation

Automation Technologies:

- Automated Packing Stations: Select appropriate box size, seal, and label.

- Vision Inspection Systems: Ensure label accuracy and placement.

- Robotic Arms with End Effectors: Handle fragile items and custom packaging.

Benefits:

- Consistent packaging quality

- Reduction in damages

- Higher throughout

6. Dispatch and Shipping

Key Tasks:

- Sorting packages by destination

- Loading delivery trucks

- Updating shipment status in systems

Automation Technologies:

- Automated Sortation Systems: Use conveyor belts and AI vision for high-speed sorting.

- Digital Dispatching Platforms: Schedule and optimize outbound deliveries.

- Driverless Forklifts and Loaders: Automate truck loading.

Benefits:

- Faster outbound operations

- On-time dispatch

- Improved carrier coordination

Integrating It All: End-to-End Workflow with a Centralized Brain

Today’s smart warehouses don’t rely on disconnected systems or manual coordination. Instead, they run on a well-integrated digital foundation, often led by a powerful Warehouse Execution System (WES). Think of the WES as the “central brain” of warehouse operations—it connects, communicates with, and controls all the moving parts of the warehouse in real-time. This coordination ensures that everything works smoothly from when products arrive to when they are shipped out.

What is a Warehouse Execution System?

A WES is a software solution that conducts warehouse operations. It bridges the gap between planning systems like Warehouse Management Systems (WMS) and the actual physical execution, including robotics and human labor. Its job is to ensure tasks are completed efficiently, resources are used wisely, and nothing is missed.

Key Integrations of WES

To do its job well, the WES connects with multiple systems and technologies:

1: Warehouse Management System:

The WMS tracks what’s in stock, where items are stored, and how inventory moves. It sends high-level plans to the WES, turning them into step-by-step actions, like assigning a robot to pick a product or telling a worker where to find it.

2. Enterprise Resource Planning:

ERP platforms handle business operations like finance, procurement, and customer orders. When an order is placed or a shipment is expected, the ERP shares that data with the WES so the warehouse can prepare accordingly.

3. Transport Management Systems:

TMS solutions manage the movement of goods outside the warehouse, such as shipping routes, carriers, and delivery schedules. The WES uses this information to plan picking and packing schedules so shipments are ready in time.

4. Internet of Things Sensors:

IoT devices provide real-time data about equipment performance, temperature, humidity, and product movement. The WES uses this data to make informed decisions, such as adjusting storage conditions for sensitive items or rerouting traffic to avoid congestion.

5. Robotic Control Systems:

These systems manage the actions of automated equipment like robotic arms, AGVs (Automated Guided Vehicles), or sorting machines. The WES sends commands to these robots and monitors their performance to keep things running smoothly.

The Outcome: Real-Time Synchronization

With all these systems integrated, the WES can make real-time decisions. It assigns tasks to robots and workers, updates inventory levels instantly, and sends alerts if something goes wrong. This end-to-end coordination boosts speed, reduces errors, and ensures every part of the warehouse works together like a well-oiled machine.

Challenges and Considerations in Warehouse Automation

While warehouse automation brings numerous benefits, such as speed, efficiency, and accuracy, it has challenges. Businesses must know these hurdles to plan better and avoid costly mistakes. From high upfront investments to cybersecurity concerns, here are some of the most common challenges companies face when adopting automation in their warehouse operations:

1. High Initial Costs:

The significant upfront investment required is one of the biggest roadblocks to warehouse automation. Automation involves the purchase of advanced hardware such as robotic systems, conveyor belts, sensors, and automated guided vehicles (AGVs). It also requires specialized software like Warehouse Execution Systems (WES), integration services, and custom development to align with business processes.

Small and medium-sized businesses may find these costs overwhelming, especially compared to traditional manual labor. Large enterprises must carefully justify the return on investment (ROI) by analyzing long-term cost savings, productivity gains, and improved accuracy. The initial cost can slow down or delay automation adoption despite the long-term benefits.

2. Complex Integration with Existing Systems:

Modern warehouse automation relies heavily on system integration. New technologies must work smoothly with existing software and hardware systems, such as Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) systems, and legacy databases. This integration is often not straightforward.

Older systems may lack modern APIs or standardized data formats, making connecting them with new, intelligent automation platforms difficult. Custom middleware or connectors may be required, increasing complexity and cost. In some cases, legacy systems need to be upgraded or replaced entirely, which can lead to extended project timelines and additional expenses.

3. Change Management and Workforce Adaptation:

Automation doesn’t just change technology—it changes how people work. Employees used to manual processes must adapt to new workflows and tools. This requires reskilling and training, which can take time and effort.

There’s also a psychological aspect to consider. Workers may fear losing their jobs to machines, leading to resistance and decreased morale. To address this, companies must communicate that automation is meant to enhance their roles, not replace them. By involving workers early in the process, offering continuous training, and positioning automation as a way to reduce repetitive, physically demanding tasks, organizations can ease the transition and encourage a more collaborative mindset.

4. Cybersecurity Risks:

Warehouse automation involves a high level of connectivity—from IoT sensors and robotic systems to cloud-based software and real-time data sharing. This connectivity introduces a range of cybersecurity risks. Hackers can exploit vulnerabilities in connected devices or unsecured networks to access sensitive operational data, disrupt workflows, or even take control of automated systems.

To combat these risks, businesses must implement strong cybersecurity measures. These include encrypted communication, multi-factor authentication, regular software updates, and network segmentation. It is also important to train employees to recognize phishing attacks and other common threats. A cybersecurity incident in a warehouse can lead to downtime, financial loss, and damage to customer trust.

Warehouse automation is a powerful tool for improving supply chain performance, but it’s not a silver bullet. Organizations must carefully plan their automation journey, considering the high initial investment, integration complexities, employee readiness, and cybersecurity requirements. With thoughtful preparation and ongoing support, these challenges can be managed, and the rewards of automation can be fully realized.

Conclusion

From inbound tracking to dispatch, warehouse task automation is no longer a futuristic vision—it’s a competitive necessity. As businesses scale and customer expectations rise, investing in smart, integrated warehouse automation is the key to staying agile, efficient, and profitable.

Whether you’re beginning your automation journey or looking to expand existing capabilities, focusing on end-to-end process integration will unlock maximum ROI.