Key Takeaways

- Autonomous operations are built incrementally, not through large-scale replacements. One decision, one exception flow, one learning loop at a time.

- Planning, execution, and learning must evolve together. Strengthening only one creates faster failure, not smarter operations.

- True autonomy requires systems to act, not just advise. Recommendations without execution simply shift work, they don’t remove it.

- Learning loops need guardrails. Without governance, autonomous systems optimize locally and damage the enterprise globally.

- Manufacturing leaders pursuing autonomy aren’t chasing technology. They’re reducing decision latency, organizational fatigue, and reliance on heroic human intervention.

Walk through most manufacturing plants today and you’ll see automation everywhere. Robots welding body frames. Bots reconciling invoices. MES systems tracking output to the second. And yet, when something unexpected happens, a late supplier shipment, a quality deviation at Line 3, a sudden spike in energy costs, the system quietly hands control back to people. Emails start flying. Excel sheets reappear. Meetings get scheduled “just to align.”

That handoff is the real bottleneck.

The next generation of manufacturing leaders is not chasing more automation for its own sake. They’re chasing autonomy. Systems that don’t just execute predefined steps, but plan, act, and learn with minimal human intervention. Not perfectly. Not blindly. But well enough that humans are pulled into judgment, not firefighting.

This shift is already underway, even if few plants describe it in those terms.

Autonomy Is Not a Big Bang Upgrade

Before going further, it’s worth clearing up a misconception. Autonomous operations are rarely launched as a single, dramatic transformation. No one flips a switch and declares the factory “self-running.”

What actually happens looks messier:

- One planning decision is delegated to an algorithm.

- One exception flow stops routing through email.

- One feedback loop closes without waiting for a weekly review.

Over time, those pieces connect.

Autonomy in manufacturing tends to emerge across three tightly linked capabilities:

- Autonomous planning

- Autonomous execution

- Autonomous learning

When one is missing, the others degrade. When all three reinforce each other, interesting things start to happen.

Also read: Leveraging Generative AI for Predictive Maintenance in Manufacturing Equipment”

Autonomous Planning: From Forecasts to Continuous Decisions

Planning has always been the most human-heavy layer of manufacturing operations. Demand planners, production schedulers, inventory managers, logistics coordinators, each working with partial information, their own heuristics, and a calendar full of meetings.

The problem isn’t lack of data. It’s timing and trust.

Traditional planning cycles are episodic. Monthly S&OP. Weekly MPS. Daily adjustments made informally. By the time a decision is approved, conditions have already shifted.

Autonomous planning systems behave differently. They don’t replace planners. They change the cadence of decisions.

What Autonomous Planning Actually Does

Instead of producing static plans, these systems:

- Continuously ingest signals: orders, supplier confirmations, machine telemetry, labor availability, and even weather and port congestion.

- Generate multiple feasible scenarios, not just one “optimal” plan.

- Commit to decisions within defined guardrails, escalating only when trade-offs exceed tolerance.

An automotive supplier offers a useful example. Their stamping operations depended on steel coils from multiple mills. Price volatility and delivery uncertainty were constant headaches. Planners spent hours rebalancing schedules when shipments slipped.

They introduced an AI-driven planning agent that:

- Re-optimized coil allocation daily

- Adjusted production sequences automatically

- Flagged only high-impact conflicts to planners

Did planners lose control? No. They gained time. Most days, they didn’t touch the plan at all. When they did, it was because the system surfaced something genuinely novel.

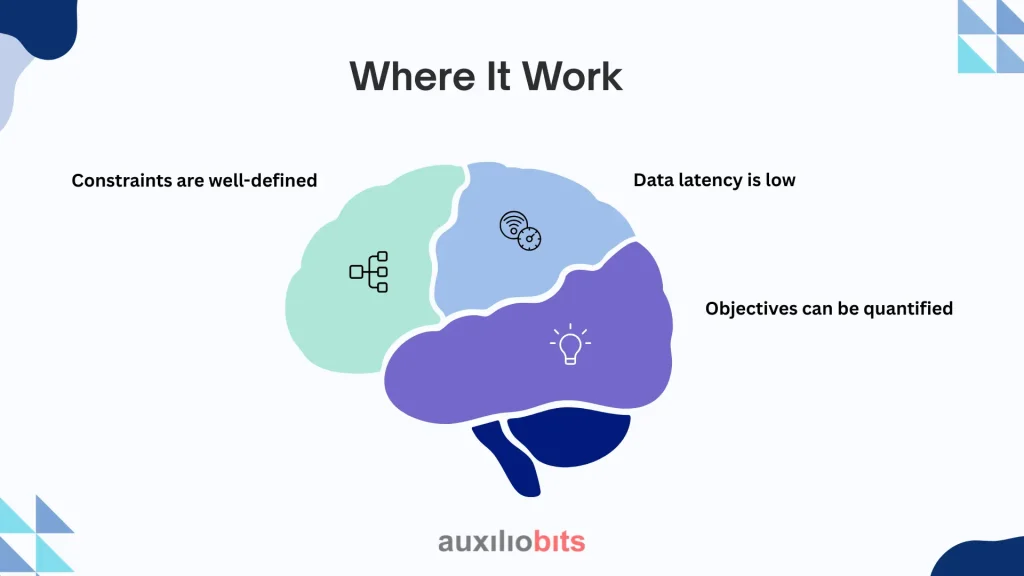

Where It Works, Where It Breaks

Autonomous planning thrives when:

- Constraints are well-defined

- Data latency is low

- Objectives can be quantified (cost, service level, throughput)

It struggles when:

- Master data is unreliable

- Business rules live only in people’s heads

- Incentives across departments are misaligned

That last point matters more than vendors like to admit. A planning agent optimizing inventory turns will clash with a sales team incentivized purely on fill rates. Autonomy amplifies organizational contradictions. It doesn’t hide them.

Autonomous Execution: Letting Systems Act, Not Just Suggest

Planning is theoretical unless execution follows through. This is where many “intelligent” systems quietly fail. They recommend actions but stop short of taking them.

Autonomous execution means systems don’t just propose decisions. They carry them out.In manufacturing, execution spans a wide surface area:

- Shop floor control

- Logistics orchestration

- Quality interventions

- Finance and compliance actions

Autonomy here is less about intelligence and more about confidence.

Production: Acting on Variability in Real Time

Consider a discrete manufacturer with mixed-model assembly lines. Machine performance varies by shift. Operator skill levels fluctuate. Material quality isn’t uniform.

In a traditional setup, supervisors intervene manually:

- Reassign operators

- Adjust takt times

- Pause lines to avoid downstream defects

Autonomous execution systems now handle some of this directly.

One electronics manufacturer deployed agents connected to MES and quality systems. When defect rates crossed a threshold:

- The agent slowed the affected station

- Rerouted work-in-progress to parallel lines

- Triggered corrective actions automatically

Supervisors weren’t removed. They were notified. Often after the fact.

Was it flawless? No. Early versions overreacted to noise. Thresholds had to be tuned. Trust had to be earned. But once stabilized, the system reduced unplanned downtime significantly.

Logistics: From Tracking to Orchestration

Logistics is a natural playground for autonomous execution because delays are frequent and options are many.

Autonomous logistics agents now:

- Reroute shipments when ports congest

- Rebook carriers based on real-time availability

- Adjust delivery promises dynamically

A global CPG manufacturer faced chronic delays in inter-plant transfers. Planners manually intervened when trucks missed slots. The result was cascading delays.

They introduced an orchestration layer that:

- Monitored ETA deviations

- Negotiated alternate routes or modes

- Updated downstream schedules automatically

Human intervention dropped sharply. Not because people weren’t capable, but because machines could act faster without waiting for consensus.

ESG: Enforcement Without Policing

ESG execution is often compliance-heavy and manual. Data gets reported long after emissions occur. Corrective actions lag.

Autonomous execution changes that dynamic.

In energy-intensive plants, agents now:

- Monitor real-time energy usage

- Shift loads during peak pricing

- Adjust production sequencing to reduce carbon intensity

One steel processor integrated carbon intensity targets directly into production execution. When energy sources shifted toward higher emissions, the system slowed non-critical processes and deferred energy-heavy operations.

No committee meeting required.

Autonomous Learning: Closing the Loop

Planning and execution without learning is just faster repetition.

The most underestimated part of autonomous operations is learning. Not model training in the abstract, but operational learning. Systems understanding which decisions worked, under what conditions, and why.

Learning From Outcomes, Not Assumptions

Many manufacturing systems are calibrated once and left untouched. Autonomous systems can’t afford that luxury.

Effective learning loops:

- Compare expected vs actual outcomes

- Attribute deviations to specific decisions

- Update decision policies accordingly

A process manufacturer learned this the hard way. Their planning agent optimized batch sizes to minimize changeovers. Throughput improved initially, but quality issues crept in.

The learning layer eventually surfaced the pattern: larger batches increased thermal drift in certain reactors, impacting yield. The agent adjusted its optimization logic. Not because someone rewrote rules, but because outcomes forced adaptation.

When Learning Goes Wrong

Learning systems can reinforce bad behavior if feedback signals are incomplete.

Examples:

- Optimizing throughput at the expense of maintenance health

- Reducing inventory while increasing stockouts elsewhere

- Meeting ESG targets by shifting emissions off-balance-sheet

This is why autonomous learning must be bounded. Guardrails, audits, and periodic human review aren’t optional. They’re part of the system.

Autonomy without governance becomes fragility.

Cross-Domain Examples: Where Leaders Are Leaning In

Autonomous operations aren’t confined to one function. Leading manufacturers are applying the same principles across domains.

Production

- Self-adjusting schedules based on machine health

- Automated quality containment actions

- Dynamic labor assignment within certified skill pools

Logistics

- Real-time carrier negotiation

- Inventory rebalancing across networks

- Autonomous dock scheduling

ESG

- Continuous emissions optimization

- Automated compliance reporting

- Energy-aware production planning

What ties these together isn’t technology. It’s intent. Leaders are deliberately deciding where humans add the most value and where systems should act independently.

Why This Shift Is Happening Now

Manufacturing has lived with automation for decades. Why autonomy now?

A few reasons surface repeatedly in executive conversations:

- Volatility is no longer episodic. It’s constant.

- Labor shortages are structural, not cyclical.

- Decision latency has become a competitive disadvantage.

- Manual coordination doesn’t scale across global networks.

There’s also a quieter driver: fatigue. Organizations are tired of heroic effort. Of smart people spending their days resolving avoidable exceptions.

Autonomous systems don’t eliminate work. They change its texture.

The Organizational Shift

One truth: autonomous operations expose leadership maturity.

When systems make decisions:

- Who owns the outcome?

- Who sets priorities when objectives conflict?

- Who intervenes when the algorithm is “technically right” but commercially wrong?

These aren’t IT questions. They’re governance questions.

The most successful implementations share a pattern:

- Clear decision rights

- Explicit escalation thresholds

- Willingness to let systems fail safely and learn

Organizations that treat autonomy as a control threat tend to throttle it. Those that treat it as a capability tend to compound gains.

There’s no finish line where operations become fully autonomous and stay that way. Markets shift. Regulations change. Products evolve.

Autonomy is something manufacturers grow into, then continuously renegotiate.

Some decisions will always require human judgment. Others shouldn’t have required it in the first place.

The leaders building autonomous operations aren’t chasing novelty. They’re chasing resilience. The ability to respond faster than conditions change. To let systems handle the predictable so people can handle the ambiguous.

And perhaps that’s the most pragmatic definition of autonomy in manufacturing:

not replacing humans, but finally letting them work on problems worthy of their attention.

The rest? Machines can take it from here.