Key Takeaways

- Scorecards alone don’t manage performance—interpretation does. Most supplier programs fail not because metrics are wrong, but because they lack the context needed to explain why results change.

- Root cause analysis is the real bottleneck, not data availability. Organizations often have the data they need, but not the capacity to connect signals across systems, timelines, and stakeholders consistently.

- AI agents are most effective when they challenge assumptions, not confirm them. The biggest value emerges when agents surface uncomfortable truths—especially when performance issues originate outside the supplier’s control.

- Early pattern detection matters more than threshold breaches. Waiting for KPIs to turn red guarantees reactive behavior; monitoring deviations and behavioral signals enables intervention before damage compounds.

- Better supplier management changes conversations, not just dashboards. When performance discussions shift from blame to diagnosis, organizations resolve issues faster, preserve supplier trust, and make escalation a last resort—not a reflex.

Supplier performance management is one of those disciplines everyone claims to do well—and almost nobody actually does.

Most large manufacturers have scorecards. Many even have quarterly business reviews. Yet when something breaks—late shipments, quality slips, unexplained cost creep—the same questions surface every time:

- Why didn’t we see this coming?

- Why does the scorecard say “green” when operations are clearly bleeding?

- Why does fixing the issue feel like guesswork rather than diagnosis?

The uncomfortable truth is that traditional supplier scorecards were never designed to explain behavior. They summarize outcomes. They lag reality. And they assume that humans will connect dots across dozens of signals, systems, and conversations—while also managing day jobs.

This is where AI agents quietly change the game. Not by replacing scorecards, but by turning them into something they were never meant to be: diagnostic instruments.

Used correctly, AI agents transform supplier performance management from a reporting exercise into a continuously learning system that identifies patterns, surfaces root causes, and—this part matters—knows when not to overreact.

Let’s unpack how that actually works in the real world.

Also read: AI Agents in Strategic Scenario Simulation for Executive Decisioning

The hidden limitations of traditional supplier scorecards

On paper, supplier scorecards look rational. You track:

- On-time delivery (OTD)

- Quality defects (PPM, NCRs)

- Cost adherence

- Responsiveness

- Compliance metrics

Then you weight them, color-code them, and publish a dashboard.

The problem isn’t the metrics. It’s the assumptions baked into how they’re used.

Scorecards assume linear cause-and-effect

Late delivery goes up → supplier performance is “bad.”

Defects go down → supplier performance is “good.”

Reality isn’t that clean. A supplier can miss deliveries because:

- Your forecasts changed late

- Engineering revised specs mid-cycle

- Logistics routes shifted due to port congestion

- A sub-supplier failed, not the tier-1 vendor

Scorecards flatten all of that into a single red number.

They freeze context in time

Most scorecards are monthly or quarterly snapshots. They don’t understand sequences.

Was this a one-off miss after 12 months of stability? Or the third small slip in six weeks that signals a deeper issue?

Humans can reason about that—sometimes. But only if they have time and access to the full trail.

They rely on human interpretation at scale

In a manufacturing enterprise with hundreds or thousands of suppliers, expecting category managers to:

- Correlate delivery data with quality logs

- Cross-check against PO change histories

- Recall conversations from six months ago

What changes when AI agents sit behind the scorecard

AI agents don’t replace scorecards. They inhabit them.

Think of the scorecard as the interface—and the agent as the analyst that never sleeps, never forgets, and never gets bored reconciling spreadsheets.

At a practical level, AI agents do three things differently:

- Continuously ingest signals, not just KPIs

- Link outcomes to upstream behaviors

- Generate explanations, not just alerts

That third point is where most automation initiatives fail—or succeed.

Scorecards become dynamic, not static

Traditional scorecards answer: What happened?

Agent-driven scorecards also answer:

- What’s changing?

- What usually precedes this pattern?

- Is this supplier deviating from their own baseline—or from peers?

How agents enrich scorecards in practice

AI agents don’t rely on a single data source. They pull from:

- ERP delivery confirmations and ASN data

- Quality systems (inspection results, NCRs, CAPAs)

- PO change logs and expedite requests

- Supplier communication (emails, portal messages, tickets)

- Logistics feeds and lead-time variability

- External signals (weather disruptions, geopolitical constraints, commodity volatility)

This matters because supplier performance rarely degrades in isolation.

A late shipment plus:

- A spike in PO amendments

- Slower response times to queries

- Increased quality rework

Agents don’t just show the score. They annotate it with context.

Root cause analysis: where AI agents earn their keep

Root cause analysis (RCA) is where most supplier performance programs quietly collapse.

Everyone agrees RCA is important. Almost nobody does it well—especially at scale.

Why? Because real RCA requires:

- Historical memory

- Cross-functional data access

- Pattern recognition across messy, incomplete inputs

That’s agent territory.

How agents perform RCA

Good agents don’t jump to conclusions. They test hypotheses.

When a supplier’s OTD drops, an agent might evaluate:

- Has the supplier’s manufacturing lead time changed—or just transit time?

- Did PO quantities increase unusually in the same period?

- Were there more engineering change notices tied to these orders?

- Did similar suppliers experience the same delay pattern?

This isn’t magic. It’s correlation, sequencing, and probability—applied relentlessly and consistently.

And unlike humans, agents don’t stop after checking the obvious.

A real-world pattern emerged: “supplier underperformance” that was not occurring

In one automotive manufacturing environment, a tier-2 supplier’s scorecard slipped from green to amber over two quarters. Delivery reliability dropped. Quality incidents ticked up.

Procurement prepared for escalation.

An AI agent flagged something odd instead:

- Delivery misses clustered only on orders with late PO revisions

- Quality issues appeared predominantly after rush orders

- Response delays aligned with weekends—on the buyer’s side, not the supplier’s

The agent’s RCA summary was blunt: “Performance degradation correlates more strongly with buyer-side planning volatility than supplier capacity constraints.”

That changed the conversation entirely. Instead of punitive action, the manufacturer stabilized forecasting rules and reduced mid-cycle changes. Supplier performance recovered without a single penalty clause invoked.

A traditional scorecard would never have told that story.

Not all root causes live inside supplier walls

This is an unpopular but necessary point: suppliers are often blamed for systemic issues upstream.

Here’s no denying that AI agents are uniquely positioned to surface that truth because they don’t care about internal politics.

They can point out:

- Chronic late approvals on the buyer side

- Excessive expedite requests tied to internal demand swings

- Design changes that correlate with quality failures

This doesn’t absolve suppliers of accountability. It sharpens it.

When escalation does happen, it’s grounded in evidence—not vibes.

From reactive escalation to preventive intervention

Traditional supplier management reacts after thresholds are breached.

Agent-based systems operate in the gray zone before thresholds turn red.

What early intervention actually looks like

Instead of:

“OTD dropped below 92%. Schedule a review.”

You get:

- “This supplier’s lead-time variance increased 18% over their six-month baseline.”

- “Response latency to PO clarifications has doubled in the past 30 days.”

- “Quality deviations are emerging on parts tied to a new sub-supplier.”

None of these alone trigger escalation. Together, they signal risk.

That’s a fundamentally different operating model.

Scorecards that adapt, instead of staying rigid

Another under-discussed advantage: AI agents allow scorecards to change weightings intelligently.

Not all metrics matter equally at all times.

For example:

- During a new product introduction, responsiveness and quality might matter more than cost adherence.

- During peak season, logistics reliability may outweigh minor quality deviations.

Agents can recommend—or automatically apply—temporary reweighting based on context. That avoids penalizing suppliers for the “wrong” things at the wrong time.

Some teams resist this at first. It feels subjective.

Ironically, it’s often more objective than fixed weightings that never reflect reality.

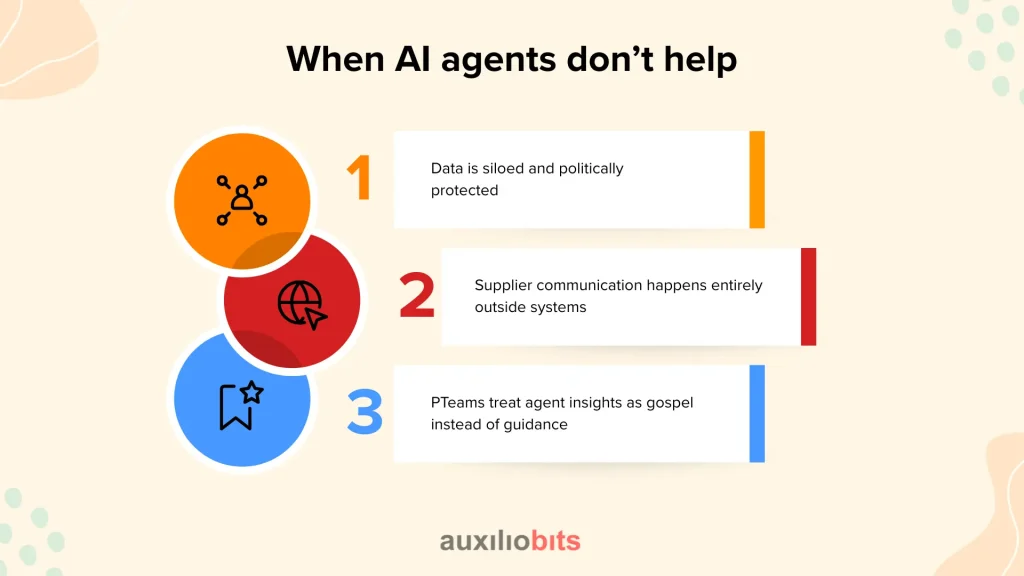

When AI agents don’t help

This isn’t a silver bullet. There are clear failure modes.

AI agents struggle when:

- Data is siloed and politically protected

- Supplier communication happens entirely outside systems

- Teams treat agent insights as gospel instead of guidance

Garbage in still produces garbage out—just faster.

There’s also a cultural risk: outsourcing judgment instead of augmenting it. The best teams use agents to inform decisions, not make them unquestionable.

A red flag? When users stop asking why an agent flagged something.

Practical ways teams deploy agent-driven scorecards today

Across manufacturing, consumer goods, and industrial sectors, patterns are emerging.

Common deployment approaches

- Scorecard copilots that explain metric changes in plain language

- RCA agents embedded in supplier portals for joint diagnostics

- Alert agents tuned to deviation patterns, not absolute thresholds

- Peer benchmarking agents comparing suppliers within similar risk profiles

Some organizations start small—one category, ten suppliers, a narrow metric set. Others go broad and course-correct.

The successful ones do something subtle: they involve suppliers early. Transparency builds trust. Surprise escalations destroy it.

The real shift: from judgment to understanding

At its core, AI-enabled supplier performance management changes the tone of the conversation.

Less: “Your score dropped. Explain.”

More: “Here’s what the data suggests changed. Do you see the same thing?”

That sounds minor. It isn’t.

It turns supplier management from adversarial oversight into shared problem-solving—without sacrificing rigor.

Scorecards still matter. KPIs still matter. Contracts still matter.

But now they sit inside a system that understands cause, not just effect.

And in complex supply networks, that difference is everything.