Key Takeaways

- Automation hasn’t failed, but it has clearly hit a ceiling. RPA delivered speed and efficiency, but manufacturing environments are too variable for rigid, rule-driven systems to keep scaling. The friction shows up in exceptions, manual handoffs, and growing operational debt.

- Agentic AI matters because it scales judgment, not just tasks. Manufacturing leaders are not chasing intelligence for novelty’s sake. They are responding to the need for faster, context-aware decisions across finance, supply chain, and production, where delays directly impact margins.

- Exception handling is the real battleground for value. The biggest gains from agentic systems come from reducing meaningless escalations, not eliminating exceptions altogether. Knowing which issues deserve attention is where intelligence pays off.

- Autonomy works only when boundaries are explicit. Successful manufacturers do not deploy free-roaming AI agents. They define decision thresholds, escalation rules, and audit trails first, then allow autonomy to operate safely within those limits.

- This shift is strategic, not technical, which is why CXOs own it. Moving from automation to agentic AI changes how decisions flow across the enterprise. It cuts across silos, governance models, and accountability structures—well beyond the scope of an IT-led initiative

Manufacturing leaders have lived through at least three waves of “this will finally fix operations.” ERP standardization. Lean programs. RPA. Each wave delivered value, but none quite lived up to the promise of a self-correcting, resilient factory or supply chain. That gap is exactly why many CXOs are now paying serious attention to agentic AI.

Such attention is not a rejection of automation. It is a recognition that automation, as most manufacturers implemented it, plateaued earlier than expected.

Automation Did What It Was Asked to Do. That’s the Problem

Robotic process automation was adopted aggressively across manufacturing finance, procurement, planning, and quality functions for a simple reason: it worked. Bots logged into SAP, extracted data, reconciled invoices, posted journal entries, created purchase orders, and moved files between systems faster than people ever could.

But RPA did only what it was told. Nothing more. Nothing less. In controlled environments, that was fine. Manufacturing environments are usually uncontrolled for long periods.

A supplier misses a shipment. A plant runs overtime due to a quality issue. A customs document arrives late. A price variance appears because a commodity index moved overnight. These are not edge cases. They are the operating reality.

Traditional automation strugRobotic process automation was adopted aggressively across manufacturing finance, procurement, planning, and quality functions for a simple reason: it worked. Bots logged into SAP, extracted data, reconciled invoices, posted journal entries, created purchase orders, and moved files between systems faster than people ever could.

But RPA did only what it was told. Nothing more. Nothing less. In controlled environments, that was fine. Manufacturing environments are usually uncontrolled for long periods.

A supplier misses a shipment. A plant runs overtime due to a quality issue. A customs document arrives late. A price variance appears because a commodity index moved overnight. These are not edge cases. They are the operating reality.

Traditional automation struggles here because:gles here because:

- Bots expect stable screens, stable rules, stable sequences.

- Exception paths explode combinatorially once variability enters.

- Any decision requiring context usually gets escalated to a human inbox.

- Maintenance quietly becomes a second job for IT and operations teams.

Many CXOs won’t say “RPA failed.” What they say, privately, is more nuanced: it stopped scaling with the business

Also read: Autonomous quality control: using computer vision agents in manufacturing lines

The Hidden Cost of Human-in-the-Loop Everything

Most automated manufacturing processes today still depend heavily on human checkpoints.

Take a typical procure-to-pay flow in a large manufacturing enterprise:

- Bot extracts invoices

- Bot performs 3-way match

- Bot flags mismatches

- Human reviews exceptions

- Human emails supplier

- Human decides whether to post or hold

- Bot resumes posting

On paper, this is automation success. In practice, exception volumes creep upward as suppliers change formats, plants follow slightly different receiving practices, or master data drifts. Over time, exception handling becomes the bottleneck.

The truth is that many automation programs simply relocated work instead of eliminating it. Humans became exception managers rather than process owners. This is where agentic AI comes into play.

What Makes Agentic Systems Fundamentally Different

Agentic AI systems are not scripts with a machine learning add-on. They are goal-oriented entities capable of observing state, reasoning about options, taking action, and adapting based on outcomes.

That definition sounds academic. The operational difference is anything but.

An agentic system can:

- Interpret ambiguity rather than fail on it

- Decide which rule applies instead of blindly applying all of them

- Learn which exceptions are worth escalating and which resolve themselves

- Coordinate across processes instead of optimizing one task in isolation

In other words, it behaves less like a macro and more like a junior operations manager who never gets tired.. This is why CXOs frame the conversation differently now. The question is no longer “Where can we automate?” It’s “Where do we need judgment at machine speed?”

Decision-Making: From Rule Execution to Trade-Off Management

Manufacturing decisions are rarely binary. They involve trade-offs. Consider supply chain planning during a disruption.

A traditional automated setup might:

- Detect delayed shipment

- Trigger an alert

- Pause downstream processes

- Notify planner

An agentic system can go further:

- Assess inventory buffers across plants

- Evaluate alternate suppliers and lead times

- Simulate production impact under different allocation strategies

- Recommend a course of action based on cost, service level, and contractual penalties

- Execute approved actions autonomously within defined boundaries

Notice the difference. One approach escalates. The other reasons.

CXOs care deeply about this distinction because decision latency is now a competitive variable. In volatile markets, the winner is often the company that decides well enough faster than competitors decide perfectly.

Exception Handling Without Drowning in Exceptions

Exception handling is where automation initiatives quietly bleed value. In manufacturing finance, for example, variance analysis is full of nuance. A price variance might be acceptable due to commodity swings. A quantity variance might be normal during ramp-up. A timing difference might resolve itself next week.

Rule-based bots treat all exceptions as equal. Humans do not.

Agentic systems can be trained to recognize patterns such as:

- Recurring supplier discrepancies that self-correct monthly

- Seasonal demand spikes that temporarily distort forecasts

- Plants with consistent receiving delays that normalize over time

This allows the system to:

- Auto-resolve low-risk exceptions

- Batch similar issues

- Escalate only those that materially affect financial or operational outcomes

The result is not fewer exceptions. It’s fewer meaningless interruptions.

Autonomy, With Boundaries That CXOs Trust

Autonomy makes executives nervous, and for good reason. No manufacturing leader wants an AI system rerouting shipments or approving payments without guardrails.

What’s interesting is that agentic AI does not require full autonomy to deliver value.

Most successful implementations operate within constrained authority:

- Monetary thresholds for approvals

- Risk scores for escalation

- Audit trails for every decision

- Human override mechanisms

Supply Chain: From Reactive Alerts to Proactive Coordination

Supply chain functions feel the pain of rigid automation first.

In a global manufacturing network, planners deal with:

- Volatile demand signals

- Multi-tier supplier dependencies

- Transportation disruptions

- Regulatory changes across regions

Automation helped with data movement and reporting. It did not help with synthesis.

Agentic systems can act as continuous planners:

- Monitoring signals across ERP, TMS, supplier portals, and external feeds

- Reconciling conflicting data instead of choosing one source blindly

- Proposing plan adjustments with rationale attached

- Learning which recommendations planners accept or reject, and why

Manufacturing Finance: Judgment at Scale

Finance leaders in manufacturing are under pressure from both directions: tighter controls and faster closes.

RPA accelerated transaction processing. It did little to improve judgment quality.

Agentic AI changes that equation in areas like:

- Accrual estimation based on historical patterns and operational signals

- Working capital optimization by balancing payment terms against supplier risk

- Audit preparation through continuous control monitoring rather than quarterly scrambles

One interesting side effect: auditors begin relying on system-generated explanations rather than raw reports. That alone saves weeks every quarter.

This is not theoretical. Several large manufacturers are already using agentic systems to narrate why certain financial outcomes occurred, not just what happened.

Production Operations: Local Decisions, Global Awareness

On the shop floor, autonomy has always existed. Operators make judgment calls constantly. The problem is that these decisions are local.

Agentic systems can bridge that gap:

- Monitoring machine performance trends across plants

- Correlating quality deviations with upstream material changes

- Suggesting parameter adjustments based on broader network behavior

Importantly, they do not replace operators. They provide operators with context that they have never had access to before.

When a system explains why it suggests slowing a line or changing a batch sequence, adoption increases dramatically. People resist black boxes. They engage with reasoning.

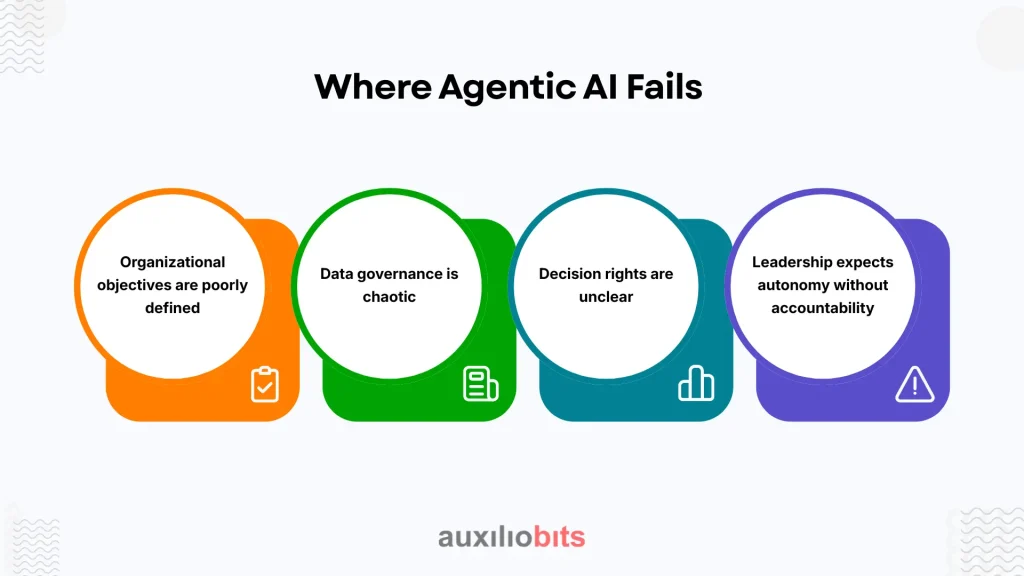

Where Agentic AI Fails

It’s easy to view agentic AI as a panacea, but it is not.

Agentic systems struggle when:

- Organizational objectives are poorly defined

- Data governance is chaotic

- Decision rights are unclear

- Leadership expects autonomy without accountability

In some cases, simpler automation is still the right answer. Not every process needs cognition. Not every decision deserves simulation.

The manufacturers seeing real returns are those that deliberately choose where agency matters.

Why CXOs Are Leading This Shift, Not IT

This transition is being driven from the top because it cuts across silos.

Agentic AI does not fit neatly into “finance automation” or “supply chain transformation.” It reshapes how decisions flow across the enterprise.

CXOs understand that:

- Speed without judgment increases risk

- Control without adaptability kills resilience

- Visibility without action is just reporting

The drive isn’t for something new; it’s a reaction to a fundamental incompatibility between their business processes and their system’s logic.

An Important, Yet Subtle, Mindset Shift

Perhaps the most important shift is philosophical.

Automation asked: How do we eliminate manual work?

Agentic AI asks: How do we scale good decisions?

That distinction explains why manufacturing leaders who were skeptical of AI five years ago are now sponsoring agentic initiatives personally.

They are not looking for fewer people. They are seeking a reduction in blind spots.

And in an industry where margins are thin, disruptions are frequent, and complexity is unavoidable, that difference matters more than any buzzword ever did.