Key Takeaways

- Unplanned downtime is costly—predictive maintenance agents reduce this risk by leveraging real-time insights from NVIDIA sensors and Azure ML.

- NVIDIA sensors enable precision monitoring, capturing vibration, temperature, pressure, and acoustic signals to detect hidden failures early.

- Azure ML ensures continuous learning, adapting predictive models to changing equipment conditions for higher accuracy and fewer false alarms.

- Autonomous agents close the loop, not just predicting failures but also triggering work orders, spare parts requests, and technician scheduling automatically.

- Enterprises adopting predictive maintenance can achieve 25–30% cost savings and 10–20% increased equipment availability, driving significant ROI and competitiveness.

In today’s manufacturing and industrial scenario, unplanned downtime is a silent profit killer. The cost of equipment failure, delayed maintenance, and reactive repair is billions annually to enterprises. Traditional maintenance strategies, such as preventive or scheduled maintenance, often fail to optimize operational efficiency as they rely on a fixed deadline rather than real-time equipment. This is the place where smart predictive maintenance agents, Nvidia sensors, and Azure machine learning (ML) are bringing revolution. These solutions not only predict equipment failures but also automate the maintenance decision-making process before they occur, reduce costs, increase uptime, and increase operational excellence.

The Need for Smart Predictive Maintenance

Manufacturing, energy, and transport industries are adopting rapid digital change strategies. However, despite the progress in ERP and IOT systems, many are still dependent on the human-lower inspection or stable maintenance program. According to McKinsey & Co., unplanned downtime costs industrial companies up to $50 billion globally per year. Predictive Maintenance Real-Time takes advantage of autonomous agents to forecast failures, use machine learning, optimize repair programs, and expand the asset lifetime. The powerful future of the Azure ML, combining the high-loyal sensor technique of NVIDIA with the powerful future analysis capabilities, can enable intelligent maintenance.

Understanding Predictive Maintenance Agents

The predictive maintenance agents are intelligent software institutions that continuously monitor, analyze, and function on tool data. Unlike traditional systems, these agents can:

- Find out discrepancies in real time

- Predicted failures with high accuracy

- Recommend or trigger corrective actions automatically.

- Learn from historical patterns to improve future predictions.

These agents are “agents” in nature—they work autonomously, coordinating between IOT tools, cloud analytics, and enterprise systems to ensure spontaneous maintenance workflows. This approach perfectly aligns with Industry 4.0 goals, where automation and AI converge to optimize industrial operations.

Role of NVIDIA Sensors in Industrial Monitoring

Smart predictive maintenance is the data acquisition at the core of maintenance, and it is the place where the NVIDIA Sensor is excellent. These sensors are designed to capture high-quality operating data, including.

- Vibration—Find out mechanical wear or imbalance

- Temperature—Monitor overheating or unusual cooling patterns

- Acoustic signal—Identify unusual sounds indicating defects

- Pressure and Flow—Measure deviations from the expected operational threshold

NVIDIA sensors support edge computing, which prepares data locally, lowering delay and enabling real-time insight. Their high-resolution data stream directly feeds into the Azure ML model, providing the required accuracy for predicting accurate failure.

Leveraging Azure ML for Predictive Analytics

Once the data is captured, the Azure machine comes into the learning game. Azure Ml enables:

- Data ingestion and pre-processing: cleaning and changing sensor data for ML modeling

- Prephysical modeling: Using algorithms to detect regression, classification, and discrepancy to predict failures

- Constant learning: The model can be taken back with new sensor data to adapt to changing operating conditions

- Integration with cloud services: safely adds future insight to the Enterprise ERP, MES, or CMMS system

By combining the NVIDIA sensor input with Azure ML, the future maintenance agents receive high prediction accuracy, reduce false alarms, and ensure maintenance resources are better allocated.

Architecture of a Smart Predictive Maintenance System

A specific future maintenance architecture using NVIDIA sensors and Azure ML includes the following layers:

1. Shore layer

- Censor occupies the operational matrix

- Edge devices to detect pre-promote data, filtering, generalization, and initial discrepancy

2. Data ingestion layer

- Azure IoT hub sensor collects data

- Events enable real-time streaming for hubs and ML pipelines

3. Analytics layer

- Azure ML models analyze data for future insight

- The algorithms for detecting discrepancies identify deviations from normal operations

- Maintenance tasks are recommended in agent decision-making

4. Integration and verb layer

- Forecast insights are sent to the ERP, MES, or CMMS system

- Maintenance agents can automatically schedule repairs, order spare parts, or trigger alerts.

This ensures spontaneous data flow for the recommendations of actionable maintenance from the layered architectural sensors, which enables end-to-end predictive maintenance.

Real-Time Data Processing and Agentic Decision-Making

The future maintenance agents should work in real time. Here is how the agent decision works:

- Continuous monitoring: sensors feed operating data continuously

- Discrepancy detection: ML models identify unusual patterns such as excessive vibration or heat

- Root Cause Analysis: The Agent evaluates which component is likely to fail

- Action trigger: Agent triggers maintenance requests, schedules technicians’ visits, or adjusts operating parameters

- Learning Loop: Results are fed back to the system, refining the future model

This autonomous response loop ensures that future staging maintenance agents not only predict failures but also improve their accuracy over time.

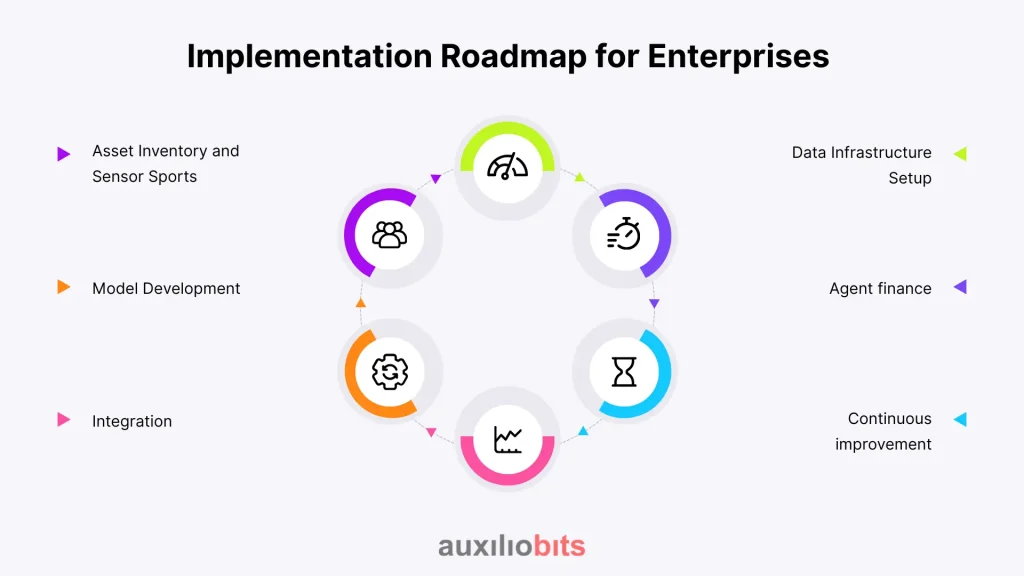

Implementation Roadmap for Enterprises

A careful plan is required to implement a future-stating maintenance system. Here is a step-by-step roadmap:

Step 1: Asset Inventory and Sensor Sports

Identify important properties and deploy Nvidia sensors at major points.

Step 2: Data Infrastructure Setup

Configure Azure IOT hub, event hub, and storage solutions for safe and scalable data ingestion.

Step 3: Model Development

Create future models using historical data. Start with the algorithm of simple regression or discrepancy detection and scale to deep learning models for complex assets.

Step 4: Agent finance

Deploy autonomous surveillance and decision-making maintenance agents capable of making decisions

Step 5: Integration

Connect the system to ERP, MES, or CMM for automated work order production and reporting.

Step 6: Continuous improvement

Monitor agents refine the algorithm for performance, retrain models, and improve accuracy and reduce downtime.

Business Impact and ROI

Smart Predictive Maintenance Agents provide tangible benefits for enterprises:

- Reduced Downtime: Predictive Alerts stop unplanned breakdowns

- Customized maintenance cost: maintenance is done only when necessary

- Extended Equipment Life: Initial identity prevents severe wear

- Better security: Reduced risk of frightening equipment failures

- Data-powered decisions: Historical insight enables strategic capital plan

A Gartner study suggests that the cost of maintenance in future maintenance can be reduced by 25%-30%, while the equipment can increase the availability of the equipment by 10%-20%. For large industrial footprint enterprises, it translates to millions of annual savings.

Challenges and Best Practices

Despite its benefits, implementing smart predictive maintenance is not without challenges:

- Data Quality: A Poor sensor can reduce calibration or missing data model accuracy

- Integration complexity: A Careful plan is required to connect heritage systems with cloud analytics

- Change Management: Employees must be trained to rely on the recommendations run by the agent

- Cyber Security: It is important to protect sensors and ML data from violations

The best practices include:

- Deposit high-loyal Nvidia sensors at important points

- Start with a pilot program before a full-scale deployment.

- Start a continuous ML model with fresh data.

- To avoid workflow disintegration, basically integrate with the existing ERP/MES system.

Conclusion

Smart predictive maintenance agents powered by NVIDIA sensors and Azure Machine Learning are reshaping how industries manage their assets. By combining high-fidelity sensor data with adaptive ML models, enterprises can not only predict failures before they happen but also automate maintenance workflows seamlessly. The result is higher uptime, lower maintenance costs, safer operations, and stronger ROI.

The path to adoption requires strategic planning—starting small, ensuring high-quality data pipelines, and progressively scaling across critical assets. With a strong focus on integration, cybersecurity, and change management, organizations can enjoy the perks of predictive maintenance and set the foundation for truly autonomous industrial operations.

In the era of Industry 4.0, enterprises that embrace smart predictive maintenance will move ahead of competitors, achieving operational excellence and long-term resilience.