Manufacturing companies worldwide have invested heavily in digital transformation. They’ve implemented advanced Enterprise Resource Planning (ERP) systems to manage their vendor data, adopted rigorous compliance policies to meet regulatory demands, and standardized vendor forms to streamline information collection. On paper, these investments should have eliminated procurement delays and inefficiencies. The procurement process — especially vendor onboarding and approval flows — should be fast, smooth, and mostly automated.

But if you work in procurement, you know that’s not the reality.

Despite these tools, many manufacturing procurement teams still find themselves entangled in lengthy email threads, manual follow-ups, and slow approval processes. Processes that should take days or hours drag on for weeks. Vendors complain about unclear status updates. Procurement teams spend more time chasing documents than negotiating contracts or strategizing supplier relationships.

This raises a critical question: If the technology and policies are in place, why does procurement still feel so manual, chaotic, and slow?

Also read: How Procurement Automation Works: Vendor Onboarding, Approval Flows, and Strategy Digitization?

The Digital Infrastructure Is There — But the Workflow Isn’t

In many manufacturing companies today, robust digital infrastructures have been established to support procurement activities. Enterprise Resource Planning (ERP) systems serve as a central hub for storing all vendor-related information, from basic contact details to compliance certifications. Compliance teams have meticulously developed detailed checklists and policies to ensure that only qualified and trustworthy suppliers are included in the system. Vendor forms, once a jumble of paper documents, have now been standardized and digitized, often available as easy-to-fill PDFs or web-based forms accessible online.

This digital foundation is crucial. It ensures data accuracy and regulatory compliance, providing a single source of truth for vendor information. On paper, the procurement process should be streamlined and efficient. But here’s the reality on the ground: while the digital tools and databases are in place, the actual workflows — the step-by-step processes that keep procurement moving — are still largely manual.

Simply put, while the technology and digital infrastructure exist, the procurement process itself hasn’t been fully digitized or automated. The workflows remain fragmented and dependent on manual intervention, resulting in low productivity and frequent bottlenecks.

Email: The Unsung (or Overburdened) Hero of Procurement

Despite the rise of advanced digital tools and platforms, email remains the default communication channel for procurement teams, even within organizations that pride themselves on being digital-first. But why does email still hold such a firm grip on procurement processes?

Here are some key reasons why email continues to be the go-to tool:

Universal Accessibility:

Email is a near-universal communication tool. Everyone inside the company and virtually every external vendor has an email address and knows how to use it. This makes email the most effective way to communicate across different organizations, departments, and time zones without compatibility issues.

Flexibility:

Unlike rigid software workflows, email allows freeform conversations. Procurement professionals can ask clarifying questions, negotiate terms, discuss exceptions, and handle unique cases without being constrained by predefined forms or steps.

Audit Trail:

Email threads automatically create a record of conversations, approvals, and decisions. This history can be invaluable for compliance, audits, and resolving disputes since it shows who said what and when.

However, this flexibility and accessibility come with serious drawbacks that hamper procurement efficiency and scalability:

No Workflow Control:

Email systems are not designed to manage complex workflows. They lack built-in mechanisms to easily identify which tasks are pending, who is responsible for the next step, or what’s causing delays. This lack of visibility makes it difficult to enforce accountability and streamline the process.

Information Overload:

Procurement teams often receive dozens, sometimes hundreds, of emails daily. This constant flood of messages can lead to critical communications being missed or overlooked, resulting in delays and errors.

Fragmented Data:

Instead of being stored in a centralized system, vendor documents, approvals, and essential information are scattered across multiple inboxes. This fragmentation makes it difficult to locate documents quickly or get a comprehensive view of a vendor’s status.

Manual Follow-Ups:

Someone on the procurement team has to continuously monitor email threads, interpret requests, identify missing information, and send reminders or escalate issues manually. This reactive mode of working consumes valuable time and increases the risk of human error.

In essence, procurement professionals end up acting like project managers — juggling hundreds of moving pieces, deadlines, and communications — all through email. This tool was never designed to orchestrate complex, multi-step processes. This mismatch between the tool and the task creates inefficiencies and frustration, slowing down procurement cycles.

What Procurement Teams Are Spending Time On?

In an ideal world, procurement teams would spend most of their time working on strategic activities — things like finding the best suppliers, negotiating better prices, analyzing supplier performance, or managing risks. However, the reality is quite different.

Most procurement professionals in manufacturing companies spend the majority of their workday handling repetitive and manual tasks that take time away from these critical strategic goals. Here’s a closer look at what that typically looks like:

1. Chasing Missing Documents from Vendors:

When a new vendor needs to be onboarded, there’s usually a long list of documents required — tax certificates, bank details, company registration papers, and compliance forms, among others. Vendors often send incomplete files, incorrect versions, or fail to attach necessary documents. Procurement staff then spend a lot of time sending emails or making calls to remind vendors to provide the missing paperwork. This back-and-forth can take days or even weeks, causing significant delays.

2. Manually Entering Repetitive Vendor Data into ERPs:

Once all the vendor information is collected, it needs to be entered into the company’s ERP system (like SAP). This means typing in the exact basic details repeatedly for each new vendor — things like names, addresses, bank account numbers, tax IDs, and contacts. This manual data entry is not only time-consuming but also prone to errors. Even minor typos can cause payment delays or compliance issues later on.

3. Following Up on Approvals from Multiple Departments:

Before a vendor can be officially approved, various departments, including finance, compliance, legal, and the business units, must review and approve the vendor details. Unfortunately, this approval process usually occurs through email chains or offline conversations, with no precise tracking or reminders. Procurement teams spend a significant amount of time chasing these approvals, sending follow-up emails, and escalating delays to keep the process moving.

4. Checking for Duplicates or Vendor Master Data Inconsistencies:

Duplicate vendor records in the ERP can lead to significant issues, including duplicate payments and inaccurate reporting. To avoid this, procurement staff often manually cross-check new vendor data against existing records. This process involves reviewing spreadsheets or running reports, and it is a tedious, error-prone task that consumes valuable time.

5. Fixing Errors Caused by Typos or Incomplete Forms:

Since much of the vendor data is collected through manual processes, such as paper forms or emails, errors are common. A simple typo in a bank account number or an incomplete tax ID can delay payment processing and require back-and-forth communication to correct. Procurement teams often find themselves firefighting these avoidable errors instead of focusing on more value-driven work.

6. Sending Constant Email Reminders to Vendors and Internal Stakeholders:

Throughout the entire vendor onboarding and management cycle, procurement teams need to keep everyone on track. This includes reminding vendors to submit documents, nudging internal approvers to review requests, and keeping stakeholders updated on the status. These constant email reminders are repetitive and distracting, consuming hours of the workday.

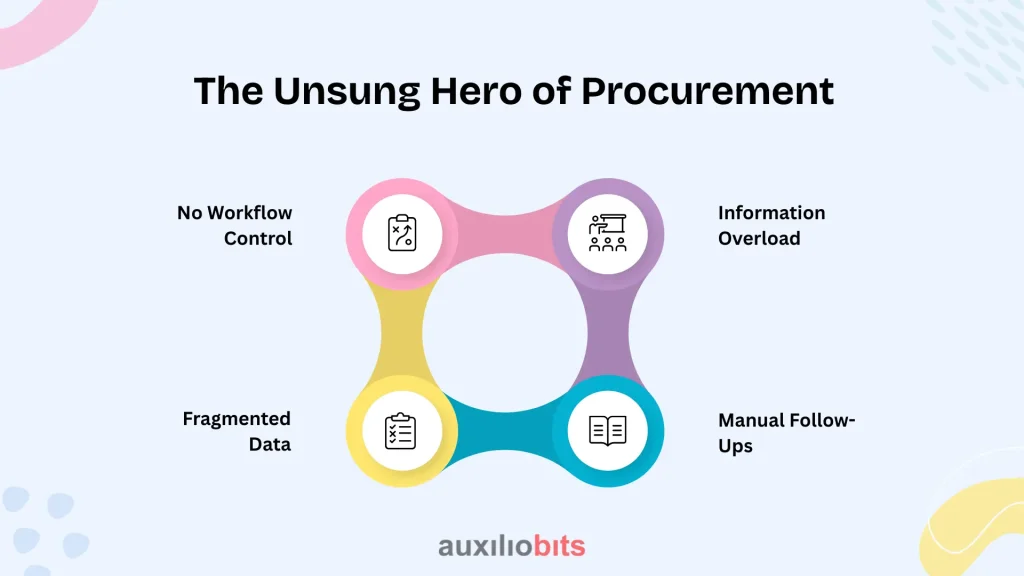

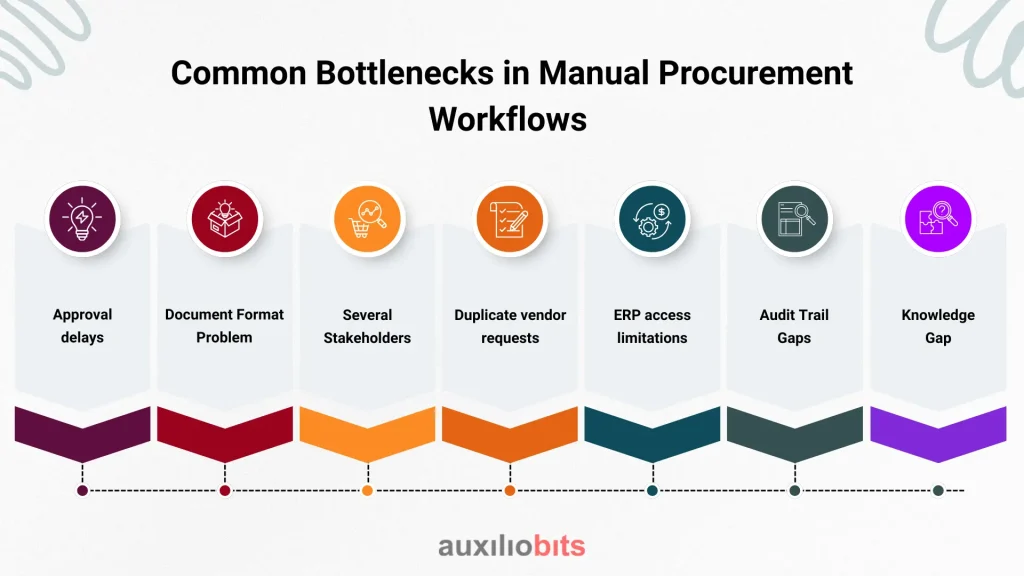

Common Bottlenecks in Manual Procurement Workflows

Manual procurement workflows in manufacturing face several common bottlenecks that slow down the entire vendor onboarding and management process. These challenges create frustration for procurement teams and lead to inefficiencies that can impact the business.

Approval delays:

One major bottleneck is approval delays. When vendor requests or documents are sent for approval, they often get stuck in busy inboxes or wait for individual approvers to find time. Because approvals are not tracked or automated, it can take days or even weeks to obtain the necessary sign-offs. This results in longer vendor onboarding cycles and delays in initiating procurement activities.

Document Format Problem:

Another issue is document format problems. Vendors frequently send documents in scanned PDFs, handwritten forms, or formats that are difficult to read and process. This results in a high rate of rejected or incomplete submissions, requiring procurement staff to spend additional time requesting corrections or clarifications. These repeated cycles add significant delays and rework.

Several Stakeholders:

The presence of too many stakeholders further complicates the workflow. Procurement, finance, compliance, legal, and operations departments are often involved separately, each with their own processes and timelines. Coordinating between all these teams without a centralized system creates slow communication and confusion, which in turn drags out the approval and onboarding steps.

Duplicate vendor requests:

Another common bottleneck is duplicate vendor requests. Without clear visibility into existing vendor records, new requests sometimes duplicate entries that already exist in the ERP system. This leads to cluttered vendor master data, causes payment errors, and wastes time resolving duplicates.

ERP access limitations:

Another delay is ERP access limitations. Not all stakeholders or procurement team members have direct access to the ERP system. Instead, they rely on intermediaries or super-users to input or retrieve data, which introduces additional steps and bottlenecks.

Audit Trail Gaps:

Manual processes often suffer from gaps in their audit trails. Because many steps are handled offline through emails, spreadsheets, or paper forms, there is no complete or reliable record for auditing purposes. This raises compliance risks and makes it challenging to demonstrate regulatory adherence during audits.

Knowledge Gap:

Finally, knowledge gaps and the reliance on tribal knowledge create dependencies on specific individuals. When standardized operating procedures (SOPs) are lacking or not documented well, it becomes challenging to maintain consistent workflows. If a key team member is unavailable, progress can come to a halt.

Step-by-Step Guide to Vendor Onboarding in SAP or Other ERP

To understand why procurement still relies heavily on manual work and emails, it helps to break down the typical vendor onboarding steps inside ERP systems like SAP:

1. Vendor Request Submission:

The process starts when a business unit or department identifies a need for a new vendor and submits a request to the procurement team. This is usually done via email or a basic ticketing system, rather than an integrated ERP module.

2. Collection of Vendor Documentation:

Procurement contacts the vendor to obtain the required documentation, including tax certificates, bank details, compliance forms, and legal certifications. Vendors often respond via email with scanned or digitally signed documents.

3. Manual Document Verification:

The procurement or compliance team manually reviews all submitted documents for accuracy and completeness, often cross-checking them against external databases or regulatory portals to ensure accuracy and completeness.

4. ERP Data Entry and Record Creation:

Procurement staff log into SAP or another ERP platform and manually enter vendor master data—name, address, tax ID, banking details, payment terms, and other fields—one by one. This step is prone to data entry errors and duplications.

5. Approval Routing:

Once data entry is complete, the vendor onboarding request is routed for approval to the relevant stakeholders, including finance, legal, and compliance teams. Approvals often occur outside the ERP, via emails or paper forms, causing asynchronous delays.

6. Status Tracking:

Since ERP systems may lack complete workflow visibility during onboarding, procurement teams often rely on spreadsheets or shared files to track approval statuses, document collection progress, and exceptions that require follow-up.

7. Vendor Confirmation and Activation:

After final approvals, procurement communicates with the vendor, typically via email, to confirm completion of onboarding and provide next steps or contractual details. The vendor is then activated in the ERP system for transactions.

The Hidden Cost of Manual Vendor Management

While manual vendor management may seem like “business as usual” for many manufacturing companies, its hidden costs are significant and far-reaching. These inefficiencies not only drain the productivity of procurement teams but also create ripple effects across the entire manufacturing operation.

- One of the most immediate consequences is delayed production schedules. When the vendor onboarding process is slow or error-prone, purchase orders (POs) are delayed. This means that raw materials or critical components may not arrive on time, which stalls production lines. In manufacturing, time is money. Even a minor delay in production can lead to missed deadlines, penalties, or lost revenue.

- Another significant cost comes from emergency procurement. When vendors aren’t onboarded in time or procurement plans fall through due to slow approvals, companies often have to make last-minute purchases to keep operations going. These emergency purchases are typically more expensive and less reliable, and can quickly erode margins.

- Supplier dissatisfaction is also a significant but often overlooked cost. Vendors are partners in the manufacturing value chain. When they face repetitive document requests, delayed onboarding, or slow payments caused by data entry errors, their trust in your company decreases. Unhappy suppliers may deprioritize your orders or even refuse to work with you in the future, which impacts supply chain stability and performance.

- Manual processes also pose serious compliance risks. When documents are managed via email or stored in inconsistent formats, it becomes challenging to maintain a clean audit trail. During audits or certification processes, missing documentation, inconsistent approvals, or unrecorded actions can expose the company to regulatory penalties or reputational damage.

- Additionally, ERP data quality suffers in a manual environment. Inconsistent or incomplete vendor information leads to inaccurate reporting and unreliable analytics. Decision-makers rely on clean data to manage costs, assess supplier performance, and forecast procurement needs. Poor vendor data creates a chain reaction of inefficiencies in other downstream processes, including invoicing, payments, and even inventory planning.

Key Industry Insights That Highlight the Impact:

- 70% of supplier onboarding failures stem from manual errors.

This includes incorrect data entries, missing documents, and untracked approvals—all of which can be avoided with automation. - Companies that implement automated onboarding reduce cycle times by up to 60%.

Faster onboarding leads to quicker purchasing, stronger supplier relationships, and smoother production processes. - Poor vendor data contributes to 25% inefficiency in downstream processes.

This affects everything from invoice processing to financial reconciliation and inventory control, resulting in both time and financial losses.

What Automation Brings to Procurement?

Manual processes consume time, introduce errors, and keep procurement teams trapped in a cycle of inefficiency. Automation changes that. By streamlining document handling, approvals, data entry, and communication, intelligent automation tools eliminate the repetitive work that slows procurement down.