Key Takeaways

- Most automation stalls not because processes fail—but because decisions arrive too late. Manufacturing systems execute faster than humans can decide. The real constraint today is decision latency, not task execution.

- Process automation without decision automation amplifies delays, not efficiency. Bots create orders, alerts, and tickets instantly, but value leaks out while approvals, prioritization, and trade-offs wait in human queues.

- Agentic decisioning works where static rules collapse. Manufacturing environments change too frequently for hard-coded logic. Decision agents succeed by reasoning within constraints, not enforcing brittle rules.

- The highest ROI use cases sit between detection and action. Rescheduling, quality triage, inventory substitution, and maintenance prioritization all fail when decisions are slow—or overly cautious.

- Decision automation scales judgment, not headcount. The goal isn’t removing humans from the loop, but letting experienced judgment operate continuously, consistently, and at machine speed.

For the last decade, manufacturing automation conversations have been dominated by processes. Map the workflow. Remove manual steps. Add bots. Reduce cycle time. Measure savings.

And to be fair—this work mattered. It still does.

But in many plants and supply chains today, the real bottleneck is no longer execution. It’s decision latency.

The line is automated. The ERP is configured. The dashboards are live.

Yet people are still waiting—sometimes hours, sometimes days—for someone to decide what to do next.

That gap is where most manufacturing automation programs quietly stall.

Also read: Why Manufacturing Automation Programs Fail—and How to Fix Them

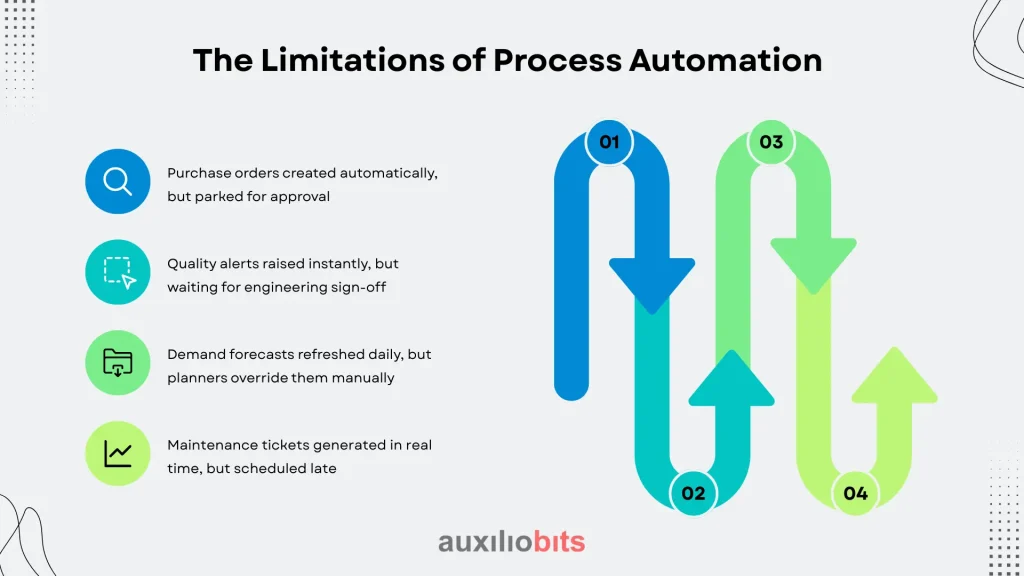

The Limitations of Process Automation

Walk into any mid-to-large manufacturing organization and you’ll see it:

- Purchase orders created automatically, but parked for approval

- Quality alerts raised instantly, but waiting for engineering sign-off

- Demand forecasts refreshed daily, but planners override them manually

- Maintenance tickets generated in real time, but scheduled late

The process fires. The system works.

Then everything pauses.

Why? Because the next step requires judgment.

Most automation programs stopped at task execution, assuming decisions would remain human. That assumption worked when volumes were lower, lead times longer, and variability manageable. It breaks under today’s conditions.High SKU proliferation. Shorter production runs. Volatile suppliers. Compliance scrutiny.

Decisions now arrive faster than humans can reasonably absorb them.

Decision Latency: The Invisible Cost

Decision latency isn’t just delay. It’s compounded impact.

A late decision in manufacturing rarely stays local. It ripples.

Take a common example: supplier delay detection.

- A supplier misses a shipment window by six hours.

- The ERP flags it. No action is taken.

- Planning waits for procurement.

- Procurement waits for confirmation.

- Production reschedules manually the next morning.

By then:

- Overtime costs rise

- Secondary suppliers are unavailable

- Customer commitments are renegotiated late

The process worked. The decision arrived too late.

Multiply this across hundreds of micro-decisions per week—rescheduling, substitutions, quality holds, expedite approvals—and you start to see why throughput plateaus despite automation investments.

Where Humans Still Struggle

There’s a quiet truth manufacturing leaders don’t always say out loud:

Humans are good at complex reasoning, but bad at repetitive, time-sensitive judgment under load.

Especially when decisions involve:

- Multiple systems

- Conflicting KPIs

- Probabilistic outcomes

- Partial or noisy data

Consider a production planner juggling:

- Demand variance

- Labor availability

- Machine downtime

- Material substitutions

- Service-level commitments

Asking that planner to make 40 such calls per day—consistently, optimally, without bias—is unrealistic. Even the best planners default to heuristics. Or habit. Or last week’s workaround.

That’s not a skills problem. It’s a cognitive one.

Decision Automation Is Not “More Rules”

This is where confusion often creeps in. Decision automation is not about encoding every choice into static rules. Most manufacturers tried that. It failed fast.

Hard-coded logic collapses when:

- Conditions shift

- Exceptions stack

- Trade-offs change

- Incentives conflict

What works instead is decisioning that adapts, learns, and reasons within guardrails.

This is where agentic decision systems start to matter.

Agentic Decisioning: What’s Actually Different

An agentic decision system doesn’t just execute instructions. It evaluates context, weighs constraints, and takes action—or escalates—based on intent.

In manufacturing terms, that means:

- Understanding why a decision matters, not just what to do

- Evaluating multiple options, not a single path

- Acting autonomously within defined risk thresholds

Think less “if-then automation” and more “situational judgment at machine speed.”

Not magic. Not sentient. But materially different from bots.

Real Manufacturing Use Cases Where Decision Automation Works

1. Dynamic Production Rescheduling

Most plants still reschedule once per shift or per day. Reality doesn’t wait that long.

An agentic decision system can:

- Monitor machine health, material availability, and order priority continuously

- Re-sequence jobs when disruption probability crosses a threshold

- Decide not to reschedule when instability would cause more harm

This nuance matters. Over-rescheduling is as damaging as under-reacting.

2. Quality Deviation Triage

Quality systems are excellent at detection. They’re terrible at prioritization.

When a deviation occurs:

- Does production stop immediately?

- Is containment sufficient?

- Can rework happen downstream?

- Is regulatory exposure involved?’

These are decisions, not alerts.

Agentic quality decisioning can:

- Assess severity using historical defect propagation

- Compare customer risk vs. scrap cost

- Trigger containment automatically—or escalate with context

The win isn’t fewer defects. It’s fewer overreactions.

3. Inventory Substitution Decisions

Material shortages are now routine, not exceptional.

Humans often default to:

- Waiting for exact materials

- Or substituting conservatively

Decision agents can evaluate:

- Approved alternates

- Impact on downstream processes

- Certification constraints

- Cost implications

And decide in minutes what previously took days and three meetings

4. Maintenance Prioritization Beyond Calendars

Predictive maintenance systems generate insights. Maintenance teams still decide what to act on first.

Agentic decisioning adds:

- Production criticality weighting

- Spare part availability

- Safety risk assessment

- Downtime window optimization

This avoids the common trap of fixing what’s loudest, not what’s most dangerous.

When Decision Automation Fails

Let’s be honest—this approach isn’t a silver bullet.

Decision automation fails when:

- Governance is vague

- Risk tolerance is undefined

- Data quality is assumed instead of validated

- Humans are removed entirely

The best implementations treat decision agents as co-pilots, not replacements.

Humans still:

- Define objectives

- Set escalation thresholds

- Override when context changes

Ironically, decision automation works best in organizations comfortable saying, “We don’t need perfect decisions. We need timely, defensible ones.”

A Shift in How Manufacturing Operates

There’s a cultural change here that often gets overlooked.

Process automation asks: How do we do this faster?

Decision automation asks: Should we even do this right now?

That shift changes everything—from KPIs to org design.

You start measuring:

- Decision turnaround time

- Escalation quality

- Reversal frequency

- Decision confidence, not just outcomes

Manufacturing leaders who embrace this stop obsessing over headcount and start focusing on decision throughput.

Why This Matters Now

Manufacturing volatility isn’t cyclical anymore. It’s structural. Supply networks are fragile. Regulations tighten. Customization increases. Margins compress.

In that environment:

- Faster execution without faster judgment just amplifies mistakes

- More data without automated reasoning increases noise

- More dashboards don’t reduce hesitation

Decision automation doesn’t replace experience. It scales it.

The planners, engineers, and managers you trust today—imagine their judgment operating continuously, across thousands of micro-decisions, without fatigue.

That’s the real promise. Not efficiency theatre. Not buzzwords.

There should be fewer pauses where momentum is lost, waiting for someone to make a decision.

And in manufacturing, momentum is everything.