Key Takeaways

- Goods receipt matching breaks because manufacturing workflows are asynchronous by default. Receipts, invoices, and POs rarely move in lockstep. Systems that assume clean sequencing inevitably generate exceptions, regardless of how strict the matching rules look on paper.

- 2-way matching is not a compromise—it’s a control decision. When categories are predictable and suppliers are governed, 2-way matching often reduces risk by eliminating unnecessary noise. Enforcing 3-way matching everywhere increases friction without improving accuracy.

- Most invoice mismatches are created at the receiving dock, not in AP. Casual quantity adjustments, missing context, or poorly captured receipt data quietly undermine downstream matching. Fixing receipt discipline does more than tuning invoice logic ever will.

- Exception handling determines whether touchless matching scales or collapses. High-volume environments don’t fail because exceptions exist—they fail when every exception is treated as equally urgent and routed manually without context.

- The real payoff of touchless matching is trust, not speed. When teams trust that payments reflect reality on the floor, attention shifts from reconciliation to supplier performance, inventory health, and cash management—which is where manufacturing finance actually creates value.

In high-volume manufacturing, “goods receipt” sounds deceptively simple. A truck arrives. Pallets get unloaded. Someone checks quantities. Someone else posts a GRN in the ERP. Finance waits for an invoice. Payment follows.

That’s the textbook version. Anyone who’s actually run a plant—or sat in on a month-end close—knows that goods receipt matching is where order-to-pay either hums or quietly bleeds time, money, and credibility.

Touchless matching has been a procurement and AP aspiration for years. Not because it’s fashionable, but because manual intervention at scale simply doesn’t hold. When you’re processing thousands of line items per day across multiple plants, vendors, and logistics partners, even a 2% exception rate turns into a daily fire drill.

This piece focuses narrowly on what actually matters: 2-way and 3-way matching, why they fail in the real world, and how manufacturers are making goods receipt matching mostly touchless—without pretending exceptions will ever disappear.

Why Goods Receipt Matching Is Still a Bottleneck

Most manufacturing enterprises already have:

- An ERP capable of 2-way and 3-way matching

- Defined tolerance rules

- Documented processes

- A procurement policy that looks airtight on paper

And yet, GR-invoice mismatches keep piling up.

The reason isn’t a lack of systems. It’s volume, variability, and reality.

A few patterns seen repeatedly:

- Line-level mismatches caused by partial deliveries

- Quantity differences because receiving happens before paperwork catches up

- Price variances from outdated contracts or missed change orders

- Units of measure quietly drifting between PO, ASN, and invoice

- Human “fixes” applied at receiving that never propagate downstream

When volume is low, people absorb this with tribal knowledge. When volume is high, tribal knowledge collapses.

That’s where touchless matching becomes less about automation hype and more about survival.

Also read: Building Autonomous AI Agents for Manufacturing Control Systems

2-Way vs. 3-Way Matching: What the Diagrams Don’t Show

On a slide, the difference is trivial.

- 2-way match: PO ↔ Invoice

- 3-way match: PO ↔ Goods Receipt ↔ Invoice

In practice, the choice is political, operational, and deeply contextual.

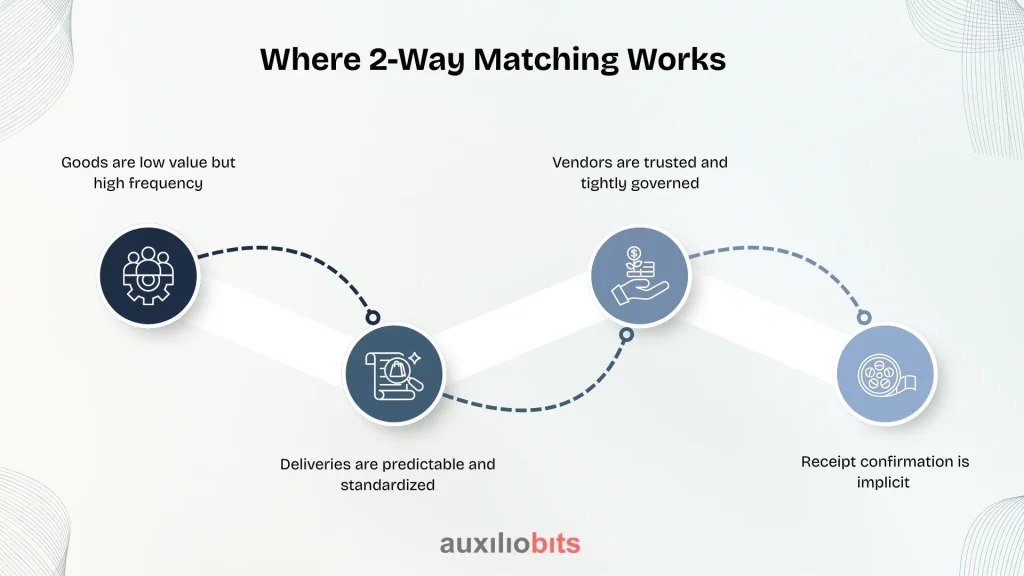

Where 2-Way Matching Works

2-way matching isn’t lazy. It’s pragmatic when conditions are right.

It works well when:

- Goods are low value but high frequency

- Deliveries are predictable and standardized

- Vendors are trusted and tightly governed

- Receipt confirmation is implicit (e.g., recurring consumables)

Think packaging materials, indirect MRO items, or catalog buys from long-standing suppliers.

In one automotive components, over 40% of POs were technically eligible for 3-way matching—but enforcing it added zero risk reduction and plenty of delay. They moved those categories to controlled 2-way matching with tighter price tolerances. Exception rates dropped. AP stopped chasing ghosts.

Where 3-Way Matching Is Non-Negotiable

3-way matching earns its keep when:

- Materials are inventory-critical

- Quantities fluctuate shipment to shipment

- Quality inspections gate acceptance

- Payment must reflect what actually landed on the dock

Raw materials, sub-assemblies, imported components—this is where skipping the goods receipt step is reckless.

The problem is that traditional 3-way matching assumes clean, synchronized data. Manufacturing never offers that luxury.

Why Matching Breaks Down at Scale

Theoretically, 3-way matching should be bulletproof. In reality, it fails for boring, repeatable reasons.

1. Timing Asymmetry

Goods arrive before paperwork. Or paperwork arrives before goods. Or invoices show up in bulk at month-end for deliveries spread across weeks.

ERPs hate asynchrony. Humans tolerate it. That gap is where exceptions breed.

2. Partial Receipts and Split Invoices

A single PO line becomes:

- Three deliveries

- Two invoices

- One reversed receipt

- And a handwritten note someone forgot to upload

Matching engines don’t struggle with complexity—they struggle with ambiguity.

3. Silent Data Mutations

Receiving clerks adjust quantities “just this once.” Procurement updates prices “effective immediately.” Vendors bill based on what they shipped, not what was received.

Each action makes sense locally. Collectively, they sabotage matching logic.

What “Touchless” Means

Touchless matching doesn’t mean zero exceptions. Anyone selling that is either naïve or dishonest.

What it means instead:

- The default path requires no human intervention

- Exceptions are surfaced early, clearly, and with context

- Humans handle judgment calls, not data reconciliation

The goal isn’t perfection. It’s containment.

In high-volume environments, moving from 70% manual handling to 90% touchless isn’t incremental—it’s transformational.

Building Touchless 2-Way and 3-Way Matching That Holds

Step 1: Segment Matching Strategies, Not Just Vendors

Most organizations segment vendors. Fewer segment matching logic.

You want categories like:

- Auto-approved 2-way with tight price tolerance

- 3-way with quantity tolerance but strict price control

- 3-way with inspection hold

- Conditional 2-way pending periodic reconciliation

Trying to force one matching rule across all spend is how exception queues explode.

Step 2: Treat Goods Receipt as a Data Event, Not a Checkbox

In many plants, goods receipt is still treated as an operational task, not a financial signal.

That’s a mistake.

A robust GR event should:

- Capture quantities, UOMs, and timestamps precisely

- Reference ASNs where available

- Record deviations explicitly, not via free-text notes

When receipt data is clean, matching becomes boring. Boring is good.

Exception Handling: Where Touchless Systems Prove Their Worth

Exceptions are not edge cases in manufacturing—they’re the norm. The difference is whether they’re manageable.

Common Exception Types That Never Go Away

- Quantity over-delivery within tolerance

- Price variance due to commodity index changes

- Missing goods receipt for backdated invoices

- Invoice lines merged or split differently than PO lines

Trying to eliminate these is wasted effort. Designing for them is not.

How Smart Exception Handling Works

1. Prioritization Beats Perfection

Not all exceptions deserve equal attention.

Effective systems:

- Rank exceptions by value, risk, and recurrence

- Auto-resolve known patterns

- Escalate only when judgment is required

A $20 variance on packaging should not block a $200,000 steel invoice queue.

2. Contextual Resolution

The fastest exception resolution happens when reviewers see:

- PO history

- Receipt timelines

- Prior vendor behavior

- Similar past resolutions

Without that context, people default to email chains. And once email enters the loop, touchless is dead.

A Real-World Pattern: Shrinking the Exception Funnel

One high-volume electronics manufacturer processed ~18,000 invoices per month across five plants.

Before intervention:

- ~35% required manual handling

- AP spent more time reconciling than reviewing

- Procurement blamed receiving; receiving blamed vendors

After restructuring matching and exception logic

- Touchless rate climbed to ~82%

- Exceptions clustered into three predictable buckets

- Resolution time dropped by more than half

What changed? Not the ERP. Not headcount.

They:

- Split spend into four matching archetypes

- Tightened receipt data capture

- Used rule-based auto-closure for low-risk variances

- Stopped treating every mismatch as equally urgent

The system didn’t become smarter overnight. The process became more honest.

Where Touchless Matching Fails

There are scenarios where automation should step aside.

- First-time suppliers

- Engineering changes mid-order

- Quality disputes tied to batch performance

- Regulatory or import-related holds

Forcing touchless approval here increases downstream risk. Mature teams know when to let humans slow things down.

That judgment—knowing when not to automate—is what separates operational maturity from checkbox automation.

A Subtle but Important Shift: From Matching to Confidence

The real value of touchless goods receipt matching isn’t speed. It’s confidence.

- Confidence that what was paid reflects what was received

- Confidence that exceptions are intentional, not accidental

- Confidence that scaling volume won’t collapse control

When that confidence exists, teams stop obsessing over line-item reconciliation and start paying attention to supplier performance, cash forecasting, and inventory health.

That’s a better use of everyone’s time.

Final Thought

Touchless 2-way and 3-way matching in manufacturing isn’t about eliminating people from the process. It’s about removing people from the wrong parts of the process.

Let systems do what they’re good at:

- Comparing

- Tolerating

- Flagging

Let humans do what they’re better at:

- Judging exceptions

- Interpreting context

- Making trade-offs when data disagrees

Anything else is just automation theater.