Key Takeaways

- Process selection is everything – Automating small, visible problems while ignoring high-impact inefficiencies wastes both time and money.

- Complexity lives in the shadows – Unwritten rules, side processes, and exceptions often break bots if they’re not uncovered before implementation.

- Automation is not an IT project—success requires joint ownership between business and IT, with strong governance and compliance baked in.

- Scalability and sustainability matter more than pilots – A proof of concept means little without a roadmap for enterprise-wide adoption and long-term ROI.

- Automation amplifies strengths and weaknesses. – Organizations with clear processes and governance thrive; those with messy operations only magnify their problems.

Automation in enterprises has been oversold for years. Vendors present polished demonstrations featuring bots that seamlessly navigate screens, dashboards that automatically refresh, and claims of “40% savings within six months.” Then the real work begins—inside a messy organization with old systems, missing documentation, and teams who don’t quite buy in. That’s when the cracks show.

Companies have spent enough time in automation programs—some successful, some barely crawling—to recognize a familiar pattern: organizations don’t usually fail because the technology is bad. They fail because context eats ambition for breakfast. Below are ten recurring pitfalls. If they sound uncomfortably familiar, that’s because they happen everywhere.

Also read: From RPA to APA: How Agentic AI Is Redefining Automation?

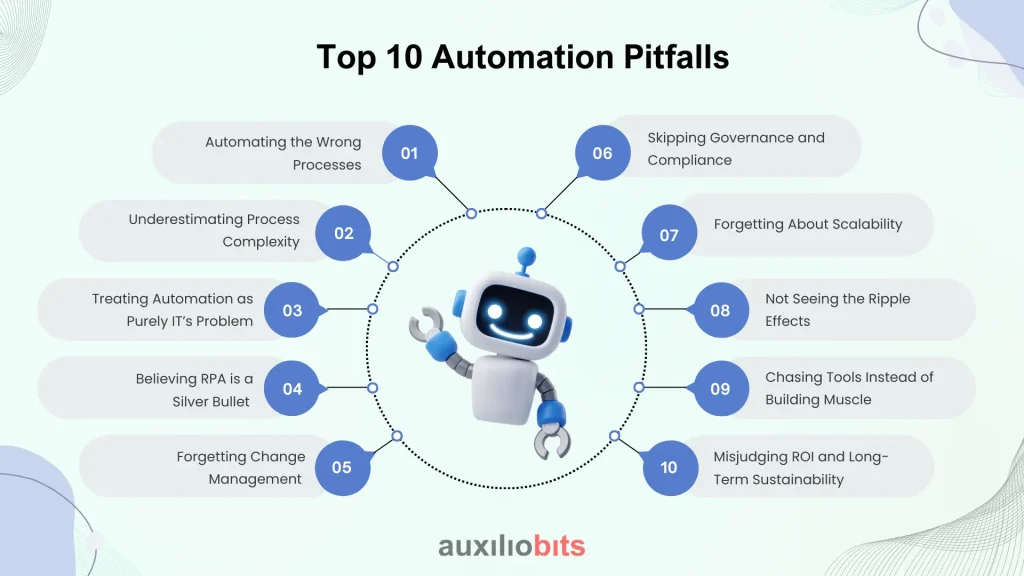

Top 10 Automation Pitfalls:

1. Automating the Wrong Processes

You’d think enterprises would start by picking the processes with the biggest pain points. They often don’t. Instead, they automate the process that someone senior feels is a problem. “Expense approvals take forever—let’s fix that.” Meanwhile, millions are locked up in vendor onboarding queues, but that’s less visible, so it stays manual.

Real-world example: A global manufacturer I worked with spent six months automating travel reimbursements. Result? A slick bot handling a few thousand claims, but no meaningful financial impact. Procurement, where the real savings were, got ignored.

Automation is expensive. If you’re not surgical in process selection, you’ll automate trivia and leave the real inefficiencies untouched.

2. Underestimating Process Complexity

On a whiteboard, every workflow looks linear: input → validate → approve → output. Reality is more like spaghetti. There are hidden branches, side rules, and human judgment calls that never make it into the official SOP.

Three killers:

- Shadow processes: the Excel sheet someone updates “just in case.”

- Tribal knowledge: unwritten hacks like “always double-check vendor invoices ending in .99.”

- Dependencies nobody mentions: customs checks, weather alerts, policy exceptions.

A logistics automation pilot initially seemed straightforward on paper: automate shipment scheduling. In practice, operators cross-checked half a dozen external data sources before confirming anything. The bot handled the happy path; everything else broke within two weeks.

Lesson? Documenting a process is not the same as understanding it.

3. Treating Automation as Purely IT’s Problem

We have lost count of how many times business leaders dump automation responsibility onto IT. “They know the systems; let them handle it.” Sure, IT can build bots—but they don’t understand why the finance clerk ignores certain invoices or why a claims officer overrides a rule once in a while.

Result: bots that technically work, but nobody trusts. In one insurer, IT built a claims bot that operations flat-out refused to use. They double-checked everything manually, negating the whole purpose.

The truth is automation only works when business and IT co-own it. Otherwise, you end up with shadow automation on one side and shelfware bots on the other.

4. Believing RPA is a Silver Bullet

RPA has its uses. It’s great at bridging systems or doing repetitive keystrokes. But too many enterprises fall for the “RPA everywhere” pitch.

RPA is used to automate entire order-to-cash chains. That works until an ERP patch drops or the UI shifts slightly, and suddenly 20 bots crash in unison. Maintenance costs balloon, and leadership wonders why “automation is so fragile.”

Note: Treat RPA as duct tape. Handy for bridging, but not for building highways. APIs and native integrations are often harder upfront but way sturdier long-term.

5. Forgetting Change Management

People resist bots. Sometimes, because they worry about jobs, sometimes because they don’t trust machines with judgment calls. If you roll out automation without talking about what it means for employees, you’ll hit invisible walls of resistance.

For example, a bank’s automation program stalled for months because clerks simply refused to hand over exception-handling rules. Once leadership sat them down and clarified that jobs weren’t vanishing but roles were shifting, cooperation improved immediately.

Here’s the irony: the more human you make automation—communicating openly, reskilling staff, even admitting uncertainty—the smoother adoption becomes

6. Skipping Governance and Compliance

Bots aren’t just efficiency tools; they’re actors in a regulated environment. In banking, healthcare, and insurance, one slip and regulators are knocking. There was a time when bots logged into a patient system with admin credentials because it was “easier during development.” Easier, yes. Defensible in an audit? Absolutely not.

Governance failures usually come from:

- No version control,

- unclear bot ownership,

- or sloppy access privileges.

If those sound boring, remember: every compliance breach is boring… right up until it isn’t.

7. Forgetting About Scalability

Pilots are seductive. A bot running quietly on 50 invoices per week looks like a success story. Scale that to 50,000 invoices across five geographies, and suddenly you’re dealing with server load, time zone issues, exception floods, and five different interpretations of “the same” process.

One global manufacturer had 120 bots across five regions. Each region tweaked its bots in its own way. Within two years, they were paying more to maintain the bots than they had for the humans they’d replaced.

Automation should be built like infrastructure, not prototypes. Pilots without a scaling roadmap are just experiments.

8. Not Seeing the Ripple Effects

Automating one step in isolation can make things worse. You speed up invoice ingestion, but payment approvals can’t keep pace. You accelerate loan approvals, but fraud detection lags. You onboard customers faster, but compliance checks fail.

One finance department I worked with proudly cut processing time in half—only for collections teams to drown because invoices piled up faster than they could chase. Overall outcome: overdue accounts increased.

Automation is like squeezing a balloon. If you don’t think about end-to-end impact, pressure just shifts elsewhere.

9. Chasing Tools Instead of Building Muscle

his one is almost universal. Enterprises buy shiny platforms before they have the skills or operating model to use them. RPA here, workflow tool there, AI add-on on top—each bought for a different initiative, with no unifying governance.

The result? Tool sprawl. Teams don’t know which platform to use. Skills are scattered. Minor changes require outside consultants.

For example, a client with five overlapping automation platforms admitted they had “a tooling problem,” which is a polite way of saying the tools themselves had become the complexity.

The smarter play? Build foundational capabilities: process discovery, monitoring, exception handling, and governance. Tools should serve that foundation, not replace it.

10. Misjudging ROI and Long-Term Sustainability

Everyone loves a bold ROI promise—“30% savings within a year.” Few deliver. Not because automation doesn’t create value, but because the math is sloppy.

Common mistakes:

- Counting “time saved” without measuring if that time is actually repurposed.

- Ignoring maintenance, licensing, and support costs.

- Forgetting intangible gains like compliance strength or error reduction.

ROI in automation isn’t a quick hit. It’s an ongoing capability play. Short-term math usually flatters to deceive.

The Final Thoughts

Here’s the part vendors don’t admit: automation makes the strong stronger and the weak weaker. If your processes are messy, bots amplify the mess. If your governance is weak, automation magnifies the risk.

That doesn’t mean automation isn’t worth pursuing—it absolutely is. But treating it like a quick efficiency hack is where enterprises stumble. The organizations that succeed are the ones that respect the complexity, invest in capabilities, and admit upfront that the real work is less about code and more about organizational discipline.