Key Takeaways

- Agents augment, not replace humans. Intelligent agents handle repetitive, data-intensive, and predictive tasks, freeing humans for judgment, creativity, and strategic decision-making.

- Workforce roles evolve. Operators, engineers, and supervisors are shifting toward analytical, exception-handling, and decision-focused responsibilities rather than routine monitoring.

- Human-agent collaboration drives tangible outcomes. Real-world cases show reduced downtime, improved efficiency, and higher employee satisfaction when humans and agents work together.

- Governance, training, and culture are critical. Effective augmentation requires skill mapping, clear decision ownership, continuous training, and fostering a collaborative mindset.

- Humans remain the strategic differentiator. While agents extend operational capabilities, humans provide judgment, creativity, and relationship management that machines cannot replicate.

Manufacturing is no longer just about machines and assembly lines. It’s about collaboration—humans working alongside intelligent software agents, robotics, and AI-driven systems to achieve outcomes that neither could accomplish alone. The narrative of “automation replacing humans” has been overstated for decades. The reality emerging in modern factories is subtler: automation is not about replacement, it’s about augmentation. And if you’re in the manufacturing world, this distinction matters. A lot.

The Rise of the Agentic Workforce

Consider the assembly floor of a mid-sized automotive supplier. Traditionally, the operator would oversee a line of robotic arms, performing quality checks, adjusting torque settings, or manually handling exceptions. Enter intelligent agents—software entities capable of monitoring equipment status, predicting maintenance needs, or even orchestrating logistics for parts. These agents don’t replace the operator. They enhance their decision-making.

- Predictive insights: Agents flag which machine might fail next week. The operator decides how to reprioritize tasks.

- Data orchestration: Agents gather production metrics across multiple lines. Humans interpret nuances that algorithms might overlook, such as customer-specific tolerances or contractual obligations.

- Exception management: When a shipment delay occurs, agents can propose solutions; the human negotiates trade-offs based on context, supplier relationships, or labor constraints.

This illustrates the first principle: agents excel at repetitive, high-volume, or data-intensive tasks. Humans remain indispensable for judgment, creativity, and context-sensitive decision-making.

Also read: Why Manufacturing Automation Programs Fail—and How to Fix Them

Workforce Augmentation

Augmentation isn’t just a feel-good term HR likes to use. It’s a measurable productivity lever. Companies experimenting with hybrid teams report tangible improvements:

- Efficiency gains: One electronics manufacturer introduced agentic scheduling for assembly lines. Human planners no longer manually shuffle shifts. Production output rose 12%, and unplanned downtime dropped 18%.

- Cognitive relief: Agents absorb the cognitive load of constant monitoring, freeing skilled technicians to focus on complex troubleshooting or process innovation.

- Upskilling opportunities: When software handles mundane data entry, employees have bandwidth to learn predictive maintenance analytics, process optimization, or compliance oversight.

Notice a pattern here: augmentation is not static. As agents grow more capable, human roles evolve—not vanish. It’s a continuous interplay between capability and responsibility.

Role Evolution, Not Replacement

One of the most persistent misconceptions in manufacturing circles is that AI agents spell the end for “blue-collar” roles. Yet field evidence tells a different story:

- Process engineers: Instead of generating endless KPI reports, engineers now review exception trends flagged by agents and design interventions to reduce variability.

- Quality inspectors: Manual inspection decreases, but cognitive inspections—evaluating anomalies, determining root causes, and proposing design modifications—become the focus.

- Shift supervisors: Instead of tracking every line in real-time, supervisors interpret agent-generated dashboards and orchestrate human teams where intuition and judgment matter most.

Interestingly, the shift can create tension. Some workers feel displaced even when their roles are expanding. The nuance is crucial: workforce augmentation requires careful change management, clear communication, and training programs that emphasize complementary skills rather than fear of obsolescence.

Human + Agent Collaboration in Practice

Collaboration is not theoretical—it’s happening today in sectors like automotive, electronics, and advanced manufacturing. Let’s break down a real-world scenario:

Case: A global semiconductor plant

- Problem: Manual process tracking led to missed maintenance windows, costing millions in downtime.

- Solution: Agents monitor equipment performance, predicting maintenance needs 48 hours in advance. Humans validate predictions, schedule interventions, and handle exceptions like supplier delays or urgent orders.

- Result: 20% reduction in downtime, faster root-cause analysis, and technicians reporting higher job satisfaction—no one lost a job, but roles became more analytical.

The insight here is subtle but vital: agents are not just tools—they’re collaborators. They anticipate, analyze, and recommend. Humans contextualize, decide, and implement. The combination produces outcomes neither could achieve alone.

The Limits of Agents

It’s tempting to imagine a fully agent-driven production floor, but there are practical limits:

- Context sensitivity: Agents struggle with rare or ambiguous events. A malfunctioning sensor or sudden supply disruption might generate recommendations, but only a human can weigh trade-offs holistically.

- Trust and adoption: Operators often distrust recommendations if agents are perceived as opaque or if previous alerts were inaccurate. Transparency in decision logic is critical.

- Regulatory nuances: In highly regulated sectors like pharmaceuticals or aerospace, compliance judgments often require human validation—even if agents handle routine monitoring.

These limitations aren’t flaws; they are guardrails. Recognizing them prevents over-reliance and encourages thoughtful deployment. It’s the human-agent interplay, not autonomy for autonomy’s sake, that delivers real value.

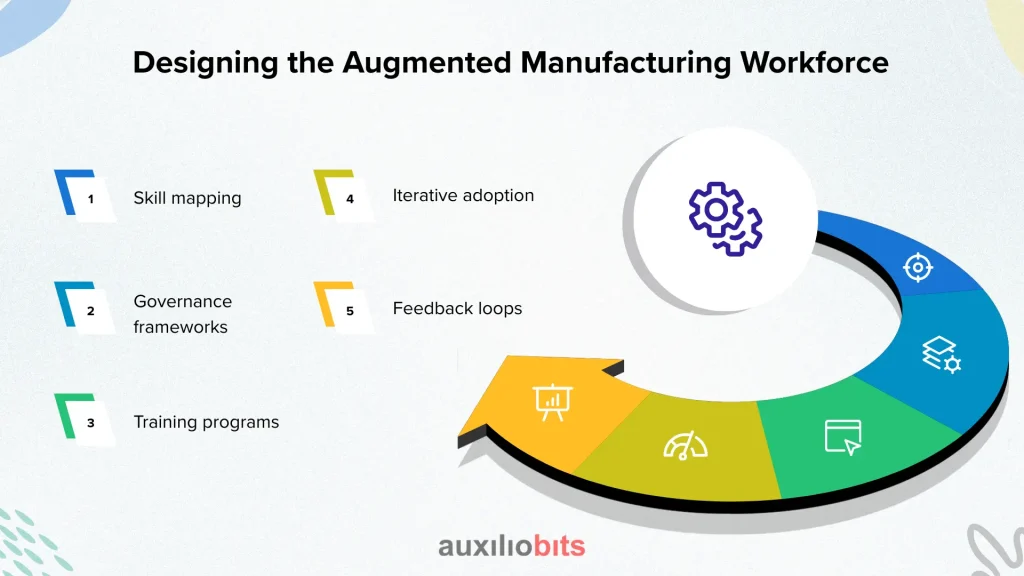

Designing the Augmented Manufacturing Workforce

How should organizations structure their workforce to embrace human-agent collaboration effectively?

- Skill mapping: Identify tasks suited for agents versus those requiring human judgment. Not all data analysis belongs to AI, and not all decisions can be codified.

- Governance frameworks: Establish clear rules for decision ownership. For example, agents may suggest schedule changes, but approval rests with human supervisors.

- Training programs: Invest in “digital fluency” and “agentic literacy.” Workers need to understand how agents reason, interpret outputs, and flag uncertainties.

- Iterative adoption: Start with high-value, low-risk processes. Measure improvements, refine agent behavior, and gradually expand into more complex workflows.

- Feedback loops: Humans provide ongoing feedback to agents, improving their predictive accuracy and alignment with operational realities.

Without these steps, augmentation risks becoming tokenistic: agents are present, but humans are not empowered to leverage their full potential.

Cultural and Organizational Implications

Augmentation changes more than daily routines; it changes workplace culture:

- Collaboration mindset: Teams must shift from “us vs. machines” to “machines + us.” Success requires trust, openness, and shared accountability.

- Empowerment over control: Supervisors transition from micro-managing tasks to enabling agents and humans to coordinate efficiently.

- Innovation acceleration: When cognitive burdens are reduced, employees can focus on process improvement, lean initiatives, or customer-driven innovation.

There’s a subtlety here: organizations that ignore culture often struggle. Advanced technology alone does not transform outcomes; the workforce must evolve alongside it.

Looking Ahead: Humans as Strategic Differentiators

Some futurists speculate about fully autonomous factories, where humans are almost ornamental. Reality paints a different picture:

- Judgment remains irreplaceable: Humans excel in navigating ambiguity, ethical trade-offs, and unexpected disruptions.

- Creativity drives improvement: Even the smartest agent cannot propose a new product variant based on market intuition. Humans do.

- Relationships matter: Suppliers, regulators, and customers value human negotiation, empathy, and discretion—qualities agents cannot replicate.

In essence, agents extend human capability, but humans remain the strategic differentiator. Factories that understand this will be agile, resilient, and capable of continuous improvement. Factories that don’t? They might achieve short-term efficiency gains but risk stagnation in complex, unpredictable environments.

The future of manufacturing work will not be a binary choice between humans or machines. It’s messy, nuanced, and fascinating. Agents will shoulder repetitive and analytical tasks, humans will focus on judgment, creativity, and context, and together they will unlock outcomes that neither could achieve alone. Workforce augmentation is not a trend—it’s an operational imperative. Companies that embrace the subtleties, rather than chasing the hype of full autonomy, will define the next era of industrial competitiveness.