Key Takeaways

- Agentic AI delivers ROI where manufacturers already feel pressure. The strongest gains appear in OPEX reduction, working capital release, and throughput stability—not in abstract productivity metrics.

- The real savings come from reducing decision noise, not headcount. By absorbing repetitive judgment calls and exception handling, Agentic AI lowers coordination costs without stripping human expertise from the process.

- Value is departmental before it is enterprise-wide. Procurement, finance, planning, and quality each experience different but tangible benefits, which together compound into enterprise-level impact.

- Autonomy works only when it is staged and governed. Agentic AI succeeds when recommendations, explanations, and actions are introduced gradually, earning trust rather than demanding it.

- Successful deployments feel quiet, not dramatic. Fewer emails, fewer side spreadsheets, and fewer reactive meetings are often the clearest signals that Agentic AI is doing its job.

Manufacturing leaders don’t wake up asking for new technology. They wake up asking why margins are under pressure despite full order books, why cash is tied up longer than it should be, and why plants that look automated on paper still depend on people firefighting exceptions all day.

Agentic AI enters this conversation not as a shiny capability, but as a response to a very specific frustration: traditional automation helped digitize tasks, but it did not materially change how decisions are made, how exceptions are handled, or how work flows across departments. In manufacturing, that gap shows up everywhere—from procurement escalations to delayed invoicing to planners manually correcting forecasts.

The business case, then, is not philosophical. It’s economic. And it becomes clearer when viewed through the same lenses CXOs already use to judge any capital or transformation initiative: operating cost, working capital efficiency, and throughput.

Evaluating ROI with a True Manufacturing Perspective

Most AI discussions get stuck at “productivity” as an abstract benefit. Manufacturing finance leaders tend to be more pragmatic, sometimes bordering on skeptical. Productivity only matters if it moves numbers that already sit on the P&L or balance sheet.

Three lenses consistently resonate in boardrooms and steering committees.

1. OPEX: reducing the cost of coordination, not just execution

Classic automation focused on execution cost. Replace a clerk. Reduce keystrokes. Shrink cycle time for a defined task.

Agentic AI, when deployed properly, attacks a different cost center: the cost of coordination.

Think about how much effort goes into:

- Chasing approvals when inputs are incomplete

- Reconciling mismatches between planning, procurement, and finance

- Interpreting policy edge cases that were never written for real life

- Handling supplier or customer exceptions that don’t fit templates

These are not “tasks” in the RPA sense. They are judgment-heavy, context-dependent, and repetitive in a frustrating way.

Agentic systems reduce OPEX by:

- Interpreting context across systems rather than pulling data from one screen to another

- Making bounded decisions without escalating everything to humans

- Knowing when not to act and instead route an issue with a reasoned explanation

Agentic agents reduced manual touchpoints not by replacing people, but by absorbing the decision noise that made those people expensive.

2. Working capital: where Agentic AI quietly outperforms dashboards

Manufacturing executives care deeply about working capital, but most tooling around it is observational. Dashboards show DSO, DPO, inventory turns. They don’t act.

Agentic AI acts.

Consider accounts receivable. Traditional automation sends reminders. Maybe it escalates after X days. But manufacturing receivables aren’t late because someone forgot to send an email. They’re late because:

- The invoice had a quantity dispute

- A delivery note mismatch stalled processing

- A customer applies deductions inconsistently

- Credit teams hesitate to release holds due to partial information

Agentic agents don’t just remind. They:

- Trace the root cause across ERP, WMS, and correspondence

- Decide whether to trigger correction, dispute, or escalation

- Adjust follow-up strategy based on customer behavior patterns

The same logic applies to inventory. Excess stock is rarely caused by bad intent. It’s caused by planning assumptions not adjusting fast enough to reality.

Agentic systems can:

- Reconcile demand signals against production constraints

- Flag when forecast overrides become habitual rather than exceptional

- Trigger corrective workflows before excess inventory becomes visible in monthly reports

The working capital impact doesn’t arrive as a single “AI benefit” line item. It shows up as fewer surprises, tighter cycles, and less manual intervention holding cash hostage.

3. Throughput: where autonomy matters

Throughput is the hardest metric to improve because it sits at the intersection of people, systems, and physics.

Manufacturing plants are full of local optimizations that hurt global flow. Expedite one order, delay another. Initiating a batch ahead of schedule may inadvertently cause a downstream line to experience shortages

Agentic AI improves throughput not by scheduling better in theory, but by responding faster in practice.

- When a machine goes down, an agent recalculates impact across orders, notifies planners, and suggests alternatives

- When material availability shifts, it adjusts priorities instead of waiting for the next planning run

- When quality exceptions appear, it routes containment actions before defects propagate

This is where autonomy earns its keep. Static rules struggle here. Human planners can manage it, but only at a limited scale and with fatigue.

Department-wise value: where Agentic AI lands

One mistake enterprises make is positioning Agentic AI as a “platform” without anchoring it in departmental realities. Manufacturing value is local before it is enterprise-wide.

1. Procurement and supply chain

Procurement teams live inside exceptions. Late deliveries. MOQ conflicts. Price deviations. Policy violations that were written years ago.

Agentic AI supports procurement by:

- Interpreting supplier communications instead of just logging them

- Deciding whether a deviation fits historical tolerance or needs escalation

- Triggering alternate sourcing workflows proactively

Not everything gets automated. And that’s intentional. The agent’s job is to reduce cognitive load, not override human commercial judgment

2. Production planning and operations

Planners already have tools. What they lack is time and uninterrupted context.

Agentic systems:

- Monitor signals continuously instead of in batch cycles

- Surface only decisions that require human trade-offs

- Learn which planners override which suggestions and why

There’s a subtle benefit here that doesn’t show up in ROI models immediately: fewer planning oscillations. Less churn. More stable schedules.

3. Finance: the earliest adopter for a reason

Finance functions tend to adopt Agentic AI earlier because pain is visible and measurable.

Use cases include:

- Expense policy interpretation rather than rule matching

- Accrual estimation based on behavior patterns

- Audit preparation without reconstructing narratives manually

The benefit isn’t just speed. It’s defensibility. When auditors ask “why,” the agent can explain its reasoning path, not just the outcome

4. Quality and compliance

Quality teams spend disproportionate time on documentation rather than prevention.

Agentic AI:

- Connects deviations to root causes faster

- Identifies recurring non-conformances that humans normalize over time

- Prepares compliance artifacts as work happens, not after the fact

This reduces compliance cost without increasing risk, which is a rare combination.

Also read: Building Autonomous AI Agents for Manufacturing Control Systems

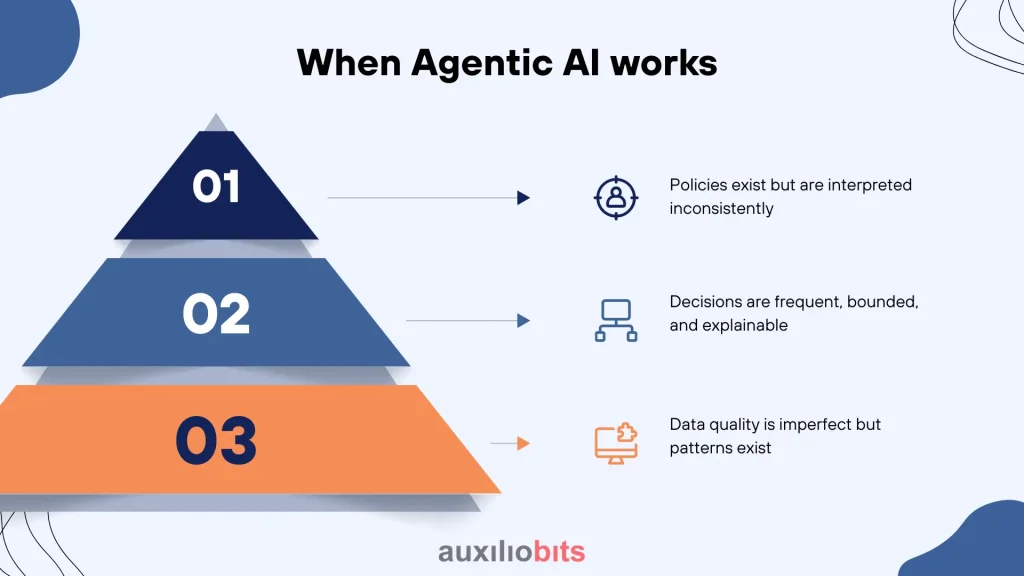

When Agentic AI works—and when it doesn’t

There’s a tendency to oversell autonomy. In manufacturing, that’s dangerous.

Agentic AI works best when:

- Policies exist but are interpreted inconsistently

- Decisions are frequent, bounded, and explainable

- Data quality is imperfect but patterns exist

It struggles when:

- The organization expects the system to fix broken master data overnight.

- Decision rights are unclear even among humans

- Leaders want “hands-off” autonomy without governance

How Auxiliobits structures value realization

At Auxiliobits, the focus has never been on deploying Agentic AI as a layer on top of everything else. The work starts much earlier. Value realization is structured around three principles.

First, anchor agents to economic outcomes, not workflows. Every agent is tied to a metric a CXO already tracks—cost per transaction, cycle time, cash release, schedule adherence. If the link is weak, the use case doesn’t move forward.

Second, design for coexistence, not replacement. Agents are introduced where human judgment is overloaded, not where it is essential. This avoids resistance and accelerates adoption.

Third, stage autonomy deliberately. Recommendation comes before action. Explanation comes before escalation. Only after trust is earned does autonomy expand.

This approach often feels slower at the start. But it avoids the trap many manufacturers fall into: impressive pilots that never survive scale.

A transition that is understated

Agentic AI in manufacturing doesn’t arrive with a big-bang moment. There is no single dashboard that suddenly proves success.

Instead, it shows up as:

- Fewer emails asking for clarification

- Fewer “temporary” spreadsheets that become permanent

- Shorter meetings because context is already aligned

- Decisions happening closer to the moment they matter

Some leaders find this underwhelming at first. Then they notice margins stabilizing despite volatility. Cash cycles are tightening without aggressive policy changes. The planners are making it home on time.

That’s the business case. The business case does not view artificial intelligence as an abstract capability, but rather as a practical response to the messy, constrained, and deeply interconnected nature of manufacturing operations.

And perhaps that’s the most telling sign. When Agentic AI is working, it doesn’t announce itself. It just removes friction that everyone had quietly accepted as normal.