Key Takeaways

- Agent networks shift inventory management from reactive to proactive—making micro-decisions continuously instead of waiting for batch-driven ERP runs.

- AWS provides the backbone for real-time coordination, with Lambda, Step Functions, Bedrock/SageMaker, and IoT Core enabling agents to sense, decide, and act across supplier, ERP, and logistics data streams.

- The biggest benefits show up financially: 8–12% reductions in working capital tied up in excess stock, and fewer catastrophic line stoppages that can cost tens of thousands per minute.

- Automation has limits—agents need governance and policy boundaries. Left unchecked, they can create technically efficient but strategically or contractually risky outcomes.

- Successful rollouts start small and scale smart, focusing on high-pain SKUs, embedding explainability, and ensuring supplier participation for true end-to-end visibility.

Walk through any large manufacturing plant and you’ll notice something striking. Some lines are humming along smoothly, while just a few meters away, another is stalled, waiting for a single missing part. Shelves may be packed with components that won’t be needed for weeks, while critical fasteners or semiconductor chips are inexplicably short. Inventory management has never been about raw visibility—it’s about balancing uncertainty, supplier reliability, and the very human tendency to “pad” numbers just in case.

Enter the new breed of agent-based networks deployed on AWS. Unlike the dashboards of yesterday, these systems aren’t passive. They operate like a mesh of decision-makers, negotiating with each other, pulling data from ERP, supplier APIs, IoT sensors, and—when well implemented—making inventory replenishment and allocation decisions that humans wouldn’t get to in time.

But here’s the catch: not every problem can or should be automated. If you’ve ever seen a procurement officer override an algorithm because of a nuanced supplier relationship, you know there’s a ceiling to blind automation. The real benefit of AWS agent frameworks is not replacing procurement teams—it’s giving them an ecosystem where autonomous processes and human judgment interact intelligently.

Why Inventory Needs More Than Just Forecasting

Traditional forecasting models—whether time-series or ML-driven—are still at the mercy of incomplete data. They might predict average demand reasonably well, but in practice:

- Unexpected events wreck forecasts. A labor strike at a key supplier in Vietnam can make your safety stock models irrelevant overnight.

- Human buffers skew the picture. Planners often inflate orders because they don’t trust lead times, leading to hidden “phantom stock.”

- ERP rigidity slows response. By the time new forecasts filter through ERP approval layers, the opportunity to adapt has already passed.

What AWS agent networks change is the time horizon of decision-making. Instead of waiting for monthly MRP runs, you get micro-decisions happening continuously: an agent sees consumption rising at Plant A, checks part availability at Plant B, looks at current in-transit shipments, and reallocates stock before anyone files a ticket.

This isn’t just theory. Automotive manufacturers piloting multi-agent systems have reported up to 18–25% reduction in line stoppages tied directly to part shortages. The reason is simple—agents don’t wait for escalation meetings.

How AWS Agent Networks Work

While it’s easy to discuss “AI agents” theoretically, their practical implementation is crucial. On AWS, agent networks designed for inventory management typically leverage:

- Amazon Bedrock or SageMaker models trained for demand sensing and anomaly detection.

- Event-driven triggers via AWS Lambda, ensuring reactions happen in near real time.

- Step Functions or managed workflows to orchestrate agent communication—who talks to whom, in what order.

- Integration connectors (via API Gateway, AppFlow, or even custom-built middleware) to ERP, WMS, and supplier portals.

The agents themselves don’t need to be heavyweight. Think of them as specialized services: one monitors supplier lead times, another checks weather disruptions, and a third looks at consumption velocity at the edge (IoT Core sensors reporting from machines). When these interact, they form a negotiation layer. For instance:

- The demand agent suggests increasing order size.

- The logistics agent counters that port congestion will delay shipments by three weeks.

- The finance agent warns about cash flow constraints.

- A coordination agent balances these and produces a revised replenishment order.

If you’re imagining this like a noisy meeting between supply chain managers, you’re not wrong. The structure is similar, except the “meeting” happens in seconds, 24/7.

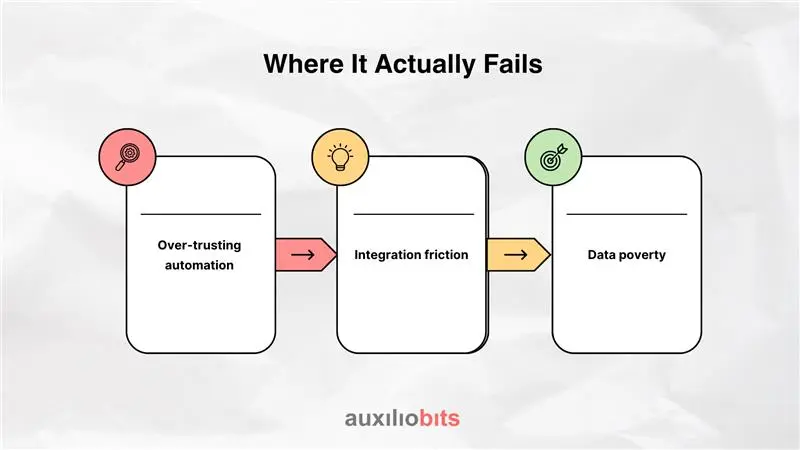

Where It Actually Fails

Three failure modes are common:

- Over-trusting automation. I’ve seen companies let agents automatically reallocate stock between sites, only to discover that moving it voided certain contractual rebates. Context matters.

- Integration friction. Legacy ERP systems (SAP ECC, Oracle EBS) are notoriously resistant to real-time data exchange. Without careful middleware, agent outputs just pile up as recommendations nobody acts on.

- Data poverty. If sensor data is unreliable or supplier portals don’t expose APIs, the “network” has nothing to feed on. Garbage in, garbage out, but with faster cycles.

So yes, agent networks shine in dynamic environments, but in organizations still struggling with data hygiene, they’ll only amplify confusion.

Practical Examples Across Industries

Some case scenarios make the benefits obvious:

- Aerospace: When a maintenance event consumes more fasteners than planned, agents immediately recalculate the impact on other service centers. No one waits for a weekly inventory call.

- Consumer electronics: Agents track component lifecycles, spotting when a supplier is phasing out a chip. Instead of discovering this after a last-time buy panic, procurement gets a six-month heads-up.

- Pharma: Cold chain sensors feed into AWS IoT, alert an agent when storage temps drift. That agent flags batches as “at risk” and requests replacements before they even hit the distribution center.

Notice a pattern? The speed of recognition and response is the differentiator, not just predictive accuracy.

The Financial Logic Behind Intelligent Inventory Control

When the conversation shifts from technology to balance sheets, the numbers tell the story more clearly than any architecture diagram. Smart, agent-driven inventory control doesn’t just promise efficiency—it directly shifts financial levers that CFOs care about.

Two categories stand out:

- Lower capital lock-in. Inventory sitting on shelves is essentially cash frozen in physical form. By allowing parts to flow more dynamically across plants and regions, agent networks trim the excess “just-in-case” stock that planners traditionally build in. Companies routinely report freeing up 8–12% of working capital while keeping service levels intact.

- Avoidance of catastrophic costs. Anyone who’s been in automotive or electronics knows what a line stoppage means—tens of thousands of dollars lost per minute. A single avoided disruption can offset months of cloud operating expenses. The math works heavily in favor of proactive reallocation.

Some benefits don’t fit neatly into quarterly reports: fewer late-night calls to source emergency airfreight, planners spending more time on strategic sourcing instead of firefighting, and healthier supplier relationships because allocation disputes are resolved quickly with data, not emotion.

Still, when pitching to finance leaders, it’s the hard metrics that win: measurable reductions in tied-up capital and a clear line from preventive action to cost savings. AWS makes this conversation easier by surfacing these numbers directly in dashboards linked to inventory KPIs.

Agents Don’t Replace Policy

One misconception is, “We’ll just let the agents figure it out.” Dangerous thinking. Agents optimize within the boundaries you give them. If corporate policy requires dual sourcing or limits exposure to certain geographies, agents need those constraints coded in. Otherwise, you’ll end up with beautifully efficient but non-compliant supply plans.

This is where human governance matters. Supply chain leaders must act less like planners and more like policy architects—designing the sandbox in which agents can safely play. The nuance here is critical: technology handles micro-adjustments; humans shape macro-direction.

When AWS Is the Right (and Wrong) Platform

AWS has undeniable strengths—global reach, ecosystem maturity, and serverless architecture that scales gracefully. But it’s not always the right choice.

- Right fit: Multinational firms already on AWS for analytics, needing rapid agent deployment across regions.

- Wrong fit: Smaller manufacturers with on-prem ERPs and limited cloud experience. For them, the overhead of building an AWS-native agent mesh might outweigh the benefits; a lighter RPA + demand forecasting combo could suffice.

This is worth stating because too many consulting decks pretend every company should leap to the same architecture. Sometimes “good enough” is better than elegant.

Building a Network That Sticks

Successful rollouts share a few traits:

- Start with high-pain SKUs. Don’t boil the ocean. Apply agents first to parts with high cost-of-failure (e.g., custom components with long lead times).

- Embed explainability. Agents need to justify why they reallocated 500 units. Black-box decisions kill trust.

- Mix autonomy with nudges. Instead of auto-executing everything, let agents recommend, then escalate only certain categories for human approval.

- Design for supplier participation. The best results come when external partners allow data exchange—otherwise it’s just an internal optimization exercise.

Each factor here reflects lessons that came with some scars. Companies that jumped straight into “global deployment” usually backpedaled after discovering local variations (customs clearance times, supplier reliability scores) that didn’t fit a one-size-fits-all agent rule.

Final Thoughts

Inventory control is one of those disciplines that sounds boring until you’re in the middle of a crisis. Then it’s suddenly existential. AWS agent networks won’t make that drama disappear, but they tilt the odds. The nuance, and it bears repeating, is not in building smarter algorithms alone—it’s in aligning organizational trust, policy, and supplier ecosystems with the technology.

Agents are fast, tireless, and rational. Humans are cautious, political, and sometimes irrational. The winning combination in supply chains isn’t choosing one over the other—it’s designing the system so both can do what they’re best at.