Key Takeaways

- Automation reduced vendor onboarding time from 30–45 days to under 5 days, eliminating bottlenecks and enabling faster execution of the procurement cycle across departments.

- The integrated RPA + AI solution introduced real-time tracking, automated validations, and digital audit trails, ensuring 100% compliance and eliminating the risk of onboarding vendors with incomplete documentation.

- A structured and transparent onboarding process improved communication, reduced vendor follow-ups, and increased satisfaction, helping attract and retain high-quality suppliers crucial for manufacturing agility.

- Over 600 hours of annual manual effort were eliminated, freeing staff to focus on strategic work, such as supplier evaluation, risk analysis, and category planning, which significantly boosted the procurement team’s efficiency.

- AI-driven document understanding standardized unstructured files, auto-extracted key fields, and flagged inconsistencies, allowing accurate, scalable onboarding even with varied document formats and sources.

In the manufacturing industry, efficiency and compliance are not luxuries — they are survival needs. One of the most critical yet overlooked processes in this domain is vendor onboarding and approval. For years, a mid-sized manufacturing enterprise with operations in three states relied on an outdated, manual vendor onboarding system built around emails, spreadsheets, physical documentation, and siloed approvals. The result? Weeks-long delays, compliance risks, vendor dissatisfaction, and inefficient use of valuable staff time.

This case study examines how the enterprise reimagined its core procurement process by leveraging a combination of Robotic Process Automation, AI-driven document understanding, and procure-to-workflow automation, resulting in a 90% faster onboarding cycle, zero compliance misses, and a substantial increase in internal productivity. It is not just a technical story — it’s a story of digital transformation that brought measurable and human-centered outcomes.

Also read: How Procurement Automation Works: Vendor Onboarding, Approval Flows, and Strategy Digitization?

The Business Background

The company is a leading manufacturer of industrial equipment, supplying heavy machinery to construction and logistics firms across North America. With approximately $400 million in annual revenue and over 1,000 employees, the company manages more than 500 suppliers, a number that continues to grow each year.

The procurement team manages vendor onboarding, supplier information updates, and risk assessments — all of which were performed manually before automation. On average, 50–100 new vendors were onboarded annually, and every onboarding process required cross-functional involvement from procurement, legal, finance, compliance, and occasionally IT.

Despite being SAP ECC users for ERP and having access to email systems like Outlook and basic SharePoint file storage, there was no integrated, end-to-end workflow for vendor onboarding. Most onboarding delays can be traced back to lost emails, incorrect data entries, and back-and-forth document verification — a digital house of cards that is ready to collapse with scale.

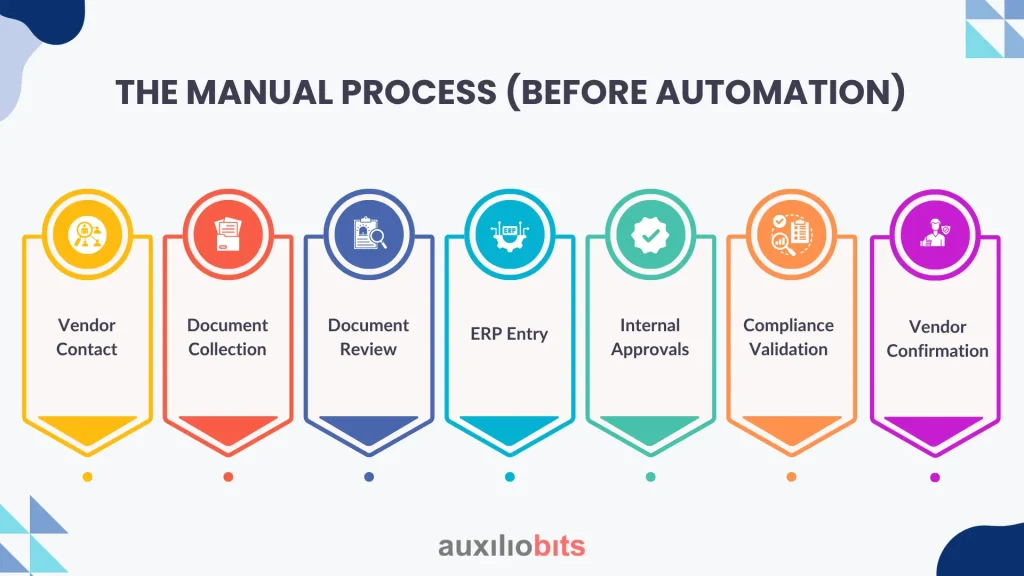

The Manual Process (Before Automation)

The legacy vendor onboarding process followed these steps:

1. Vendor Contact:

The vendor onboarding process typically begins with the procurement team identifying a new supplier and initiating contact via email. The team would manually attach a set of required documents, including a W-9 form, a bank details form, an ISO certification template, and any applicable compliance declarations. Instructions were often embedded in the email body, lacking consistency and a tracking mechanism. Vendors sometimes missed emails or misunderstood the requirements, leading to back-and-forth communication that delayed the initiation of the onboarding process.

2. Document Collection:

Once the vendor received the onboarding package, they were expected to complete the forms, gather the necessary certifications, and return them via email attachments. These documents often came in various formats — scanned PDFs, images, Word files — making consistency a challenge. Vendors occasionally omitted required pages or sent incomplete submissions. As these files landed in the inboxes of procurement executives, no central storage or tracking system existed, making it challenging to ensure that all documents were received and in the correct version.

3. Document Review:

After receiving the documents, the procurement staff had to open, read, and verify each form manually. This included verifying that fields were filled in correctly, comparing entered information with company requirements, and flagging any discrepancies. The absence of automation meant that even typos or missing fields were caught only through human inspection. With hundreds of vendors to manage, this review process became a bottleneck. Staff often had to print documents to cross-verify, which increased paperwork and the likelihood of misplacement.

4. ERP Entry:

Once the documents were deemed complete, an operations assistant manually entered the vendor’s details into the ERP system, specifically SAP ECC. Information like company name, tax ID, banking details, and address had to be keyed in field by field. Due to the high volume and risks of human error, data was occasionally mistyped or mismatched. Corrections required additional approval cycles and delayed vendor activation. Moreover, there was no real-time check to validate whether the entered data matched the original documents, increasing compliance risks.

5. Internal Approvals:

With data entry completed, onboarding progressed to internal approvals. Procurement managers, finance controllers, and compliance teams had to approve the vendor’s inclusion manually. Typically, this meant forwarding the vendor’s documents over email or printing them out for signatures. This fragmented approach led to delays when approvers were unavailable or when email threads became difficult to track. Approvals could be stuck for days without escalation or visibility. There was no centralized system to record who approved what and when.

6. Compliance Validation:

Before final onboarding, the compliance team had to verify several risk factors. This included validating tax identification numbers (PAN, GST, TIN) through external government portals, ensuring the vendor wasn’t on any blocklists, and checking bank details against voided cheques or official letters. All of these validations were performed manually — opening separate browser windows, searching databases, and recording findings in spreadsheets. The absence of an integrated tool meant slow turnaround, missed checks, and inconsistent documentation of compliance actions.

7. Vendor Confirmation:

Once all internal approvals and compliance checks were complete, the procurement team would send a confirmation email to the vendor, informing them of successful onboarding. This email often included their Vendor Code (from SAP), next steps, and key contacts. Since the process lacked automation, these communications were crafted individually and often delayed. Sometimes, vendors had to follow up multiple times to get their confirmation. The company also had no consistent log of onboarding completion dates, which made tracking vendor readiness difficult.

This entire process, though functional, was painfully slow. Onboarding one vendor took between 30 and 45 days and involved more than 50 emails, six different people, and sometimes three printed files per vendor. Human error was standard — mistyped GST numbers, expired certifications, or missing attachments often delayed approvals.

The Strategic Need for Change

Procurement leadership, after facing vendor complaints and delays in contract initiation, initiated an internal audit of the vendor onboarding pipeline. Key findings included:

High error rate:

An internal audit revealed a startling pattern—nearly 25% of all vendor onboarding cases contained data inaccuracies. These ranged from minor issues, such as typos in names or addresses, to serious mistakes, including incorrect banking information or mismatched tax IDs. Errors stemmed mainly from manual data entry and document interpretation. Each error necessitated a correction loop involving multiple departments, resulting in onboarding delays and reapprovals. Not only did this slow down procurement, but it also increased the risk of financial misrouting or compliance breaches.

Low vendor satisfaction:

Vendors routinely expressed dissatisfaction with the onboarding experience. Many reported having to follow up multiple times to understand the status of their application. Since communication happened over unstructured email threads, vendors had no clear visibility into what documents were missing, where approvals were pending, or when they could expect activation. The absence of a central tracking system meant even minor clarifications could take days. This frustration damaged relationships and deterred high-quality vendors from engaging further, impacting sourcing agility and partner trust.

Internal inefficiency:

Time-tracking data from the audit showed that staff collectively spent over 600 hours per year on non-value-adding tasks, primarily manual data entry into SAP and chasing vendors for missing documents. These repetitive activities drained procurement resources, preventing teams from focusing on more strategic work such as vendor evaluation, risk profiling, and sourcing strategy. Additionally, high staff fatigue from mundane work increased turnover risks. This inefficiency also led to onboarding queues, which slowed down contract initiation and overall project timelines.

Compliance risks:

The most alarming finding was the vulnerability to non-compliance. In several cases, vendors were fully onboarded and issued purchase orders without verified tax documentation. Either PAN or GST information was missing, outdated, or incorrect, and these were not flagged until after the audit. In a regulated industry, such oversights posed serious legal and financial risks. If identified during external audits or tax filings, they could attract penalties or audit flags. The manual nature of compliance checks made such lapses more likely, prompting an urgent need for digital controls.

With digital transformation becoming a C-level priority, the need for change was evident. The goal was not just to speed up onboarding—it was to make it accurate, auditable, intelligent, and scalable.

Technology Vision

The company’s digital transformation office proposed a bold yet realistic strategy: Redesign the vendor onboarding process using AI and automation, but without replacing SAP or building a new portal from scratch.

Their core goals were:

- Automate repetitive tasks like data entry, document validation, and approval routing.

- Use AI to extract and validate data from submitted forms (like W-9, PAN, GST, ISO certificates).

- Improve vendor experience with a self-service upload portal and real-time status updates.

- Ensure audit readiness with full digital trails of all approvals and actions.

- Integrate with existing systems, such as SAPP, Outlook, and SharePoint.

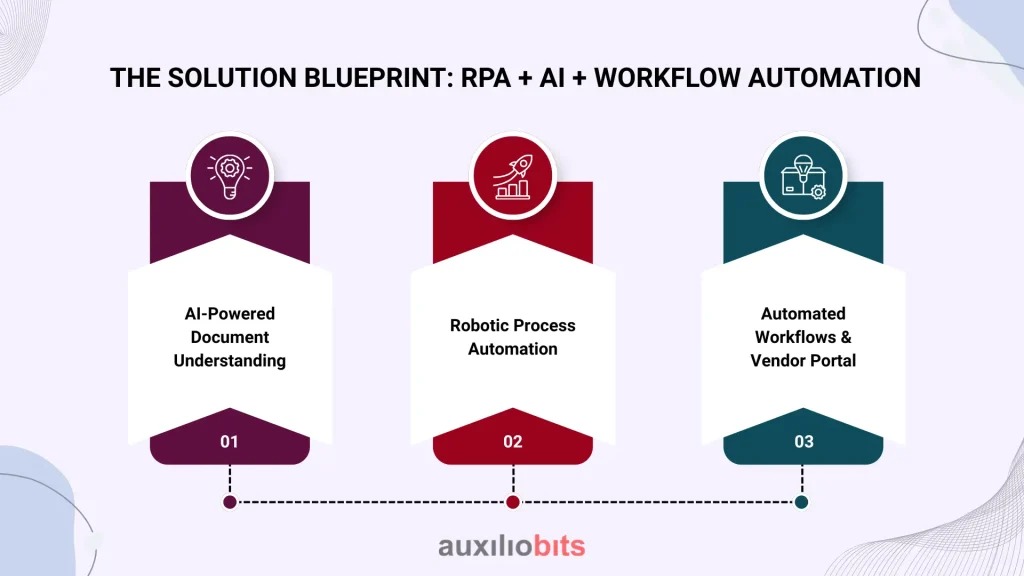

The Solution Blueprint: RPA + AI + Workflow Automation

The transformation was delivered in three integrated technology layers:

1. AI-Powered Document Understanding

Using Azure Form Recognizer, the system was trained to read vendor-submitted documents, including W-9 forms, ISO certifications, PAN cards, and voided cheques. AI models extracted:

- Company name

- Tax IDs

- Contact person

- Validity dates

- Bank details

Confidence thresholds were set (e.g., 95% for bank account numbers), and exceptions were routed to manual review queues.

2. Robotic Process Automation

UiPath bots handled:

- Reading uploaded documents from SharePoint

- Triggering document extraction via API

- Validating extracted data (e.g., GST on the govt portal)

- Entering vendor data into SAP via BAPI integration

- Triggering approval workflows based on business rules

Each bot was responsible for a modular task — improving resilience and traceability.

3. Automated Workflows & Vendor Portal

Using Power Automate, the team created:

- Multi-level approval flows (Procurement → Legal → Finance → Compliance)

- Email notifications with tracked links

- Escalation triggers if approvals are delayed for more than 48 hours.

- A vendor self-service portal built with PowerApps, allowing form upload and real-time onboarding status tracking

Before vs. After: The Transformation

| Metric | Before Automation | After Automation |

| Average Onboarding Time | 35 days | 4 days |

| Email Exchanges per Vendor | 50+ | 5–10 |

| Document Handling | Manual, Paper-based | AI-extracted & Digitally Verified |

| SAP Entry | Manual | Fully Automated |

| Approval Process | Email and Paper-based | Routed Workflow |

| Vendor Visibility | None | Portal with Status Tracking |

| Compliance Errors (Annual) | 6–8 | 0 |

| Audit Trail | Manual, Unreliable | Fully Digital |

Implementation Timeline (90 Days Total)

Phase 1 – Discovery & Mapping (Weeks 1–2)

- Interviews with stakeholders

- Mapping existing steps

- Identifying automation candidates

Phase 2 – AI Model Training (Weeks 3–5)

- Collecting 200+ real-world documents

- Training and testing extraction models

Phase 3 – RPA Development (Weeks 6–8)

- SAP data entry bot

- Compliance validation bot

- Integration with Form Recognizer

Phase 4 – Workflow Automation & Portal (Weeks 9–10)

- Building the Power Automate flow

- Designing the PowerApps portal

Phase 5 – UAT & Go-Live (Weeks 11–12)

- User training

- Go-live with 10 vendors as a pilot

- Full rollout by the end of week 12

Business Impact

In the first 6 months post-automation, the company saw tangible improvements:

- 92% reduction in vendor onboarding time

- 90% drop in manual entry errors

- Eliminated all compliance gaps

- Reduced workload on procurement ops by 80%

- Boosted vendor satisfaction scores from 2.8/5 to 4.7/5

- Estimated annual savings of $380,000, factoring in labor, delays, and compliance penalties.

Additionally, the automation led to smoother Procure-to-Pay operations. POs were generated faster. Contracts are initiated sooner. Inventory planning improved due to reliable vendor onboarding timelines.

Challenges Faced

While the automation journey delivered strong results, the transition was not without its hurdles. Below are some of the initial challenges faced during the rollout phase:

- AI Accuracy: Certain document types require additional training (e.g., blurry scanned PDFs).

- Change Management: Procurement staff initially resisted using the portal and workflows.

- Vendor Education: Some vendors experienced difficulties with the portal and required phone-based support.

- Exception Handling: A fallback mechanism for outliers had to be manually supervised initially.

But with time, training, and tweaks, these issues were resolved.

Future Roadmap

With onboarding now digitized, the company plans to:

- Automate contract creation using templates and clause extraction

- Implement vendor scoring based on performance, risk, and responsiveness.

- Extend AI to analyze ESG certifications and regulatory filings.s

Automate RFQ-to-PO processing for repeat orders

Customer Voice

Here’s what different stakeholders said after the project:

Head of Procurement:

“What used to be a black hole of emails and errors is now a clean, trackable, and efficient system. I sleep better knowing we’re audit-ready and vendor-friendly.”

Vendor Relations Manager:

“It’s night and day. We used to receive calls from angry vendors every week. Now they can see exactly where they stand.”

Finance Lead:

“No more scrambling during audits. Every approval, every timestamp, every document is a click away.”

Final Thoughts

This case study is a blueprint for any manufacturing or mid-sized enterprise struggling with outdated vendor management processes. It shows that digital transformation doesn’t require massive investments or abandoning existing systems. By layering automation intelligently, even legacy ERP systems like SAP ECC can be integrated into a modern, agile process.

The company didn’t just save money or reduce timelines — it created a better experience for both employees and vendors, making procurement a strategic asset rather than an operational bottleneck.