Walk through any modern factory and you’ll notice something intriguing: the most significant changes aren’t always visible. Yes, there are new cobots, sleeker HMIs, and more sensors bolted onto everything that moves. But the more profound shift is happening inside control cabinets and software stacks—where decision-making logic is quietly migrating from centralized systems into embedded agents living closer to machines themselves.

This isn’t about replacing PLCs or rewriting control theory. It’s about augmenting deterministic control with situational intelligence. And that distinction matters more than most vendor decks suggest.

From Rigid Automation to Situated Intelligence

Traditional factory control systems were designed for repeatability, not interpretation. PLCs execute ladder logic with impressive reliability, SCADA systems visualize states, and MES platforms coordinate workflows. Each layer does its job. The problem is that none of them think in context.

When a vibration threshold is crossed, a PLC triggers an alarm. When cycle time drifts, MES flags a deviation. What happens next usually involves a human—an operator interpreting alarms, a supervisor correlating symptoms, or an engineer deciding whether to stop the line or let it run.

Embedded agents change this dynamic by sitting inside or adjacent to control systems and continuously reasoning about state, intent, and trade-offs. Embedded agents operate not in an abstract AI sense, but rather in a deeply operational one.

Think of an agent that doesn’t just detect a temperature anomaly but asks:

- Is this machine in a transient state or steady production?

- Has this pattern preceded a bearing failure in the past?

- What happens downstream if I slow the line by 5% right now?

Those questions used to live in people’s heads. Increasingly, they’re being encoded into software entities with autonomy bounded by policy.

What “Embedded” Means

There’s a tendency to conflate embedded agents with edge AI, and while the two overlap, they’re not the same thing.An embedded agent is defined less by where it runs and more by how it interacts with control logic. It operates:

- Within tight latency constraints

- With partial, sometimes noisy data

- Under strict safety and override rules

- Alongside deterministic control loops, not instead of them

In practice, this means agents may be deployed:

- On industrial PCs sitting next to PLCs

- Inside soft PLC environments

- As containerized services on edge gateways

- Occasionally, smart devices themselves, such as vision systems, serve as examples.

What they don’t do is replace ladder logic. Anyone making a pitch who hasn’t spent much time on a factory floor is unlikely to benefit from this approach.

Instead, agents wrap around existing control structures. They observe, infer, recommend, and—when allowed—act.

Why Centralized Intelligence Falls Short on the Shop Floor

It’s tempting to push all intelligence into a central AI platform. After all, that’s where the data lake lives, where models are trained, and where dashboards sparkle.

But factories don’t behave like cloud-native systems.

Latency matters. So does determinism. A recommendation that arrives 500 milliseconds late might as well not arrive at all. Worse, centralized systems often lack the contextual fidelity of local control environments. They see KPIs, not interlocks. They focus on trends rather than specific cases.

Embedded agents operate with:

- Direct access to control signals

- Awareness of machine states that never leave the cell

- The ability to act within milliseconds, not seconds

That proximity enables a different class of intelligence—one grounded in physics and process, not just analytics.

Where Embedded Agents Shine

They’re not universal problem-solvers. Some applications fit naturally. Others don’t.

Strong use cases include:

- Adaptive process tuning in response to material variability

- Early fault detection based on subtle signal correlations

- Dynamic energy optimization during peak demand windows

- Coordinating multiple machines that technically work fine—but poorly together

More questionable territory:

- Safety-critical decision-making without redundancy

- Highly regulated processes require full traceability for every action.

- One-off custom equipment with no historical data

Integration Realities No One Likes Talking About

On paper, integrating embedded agents sounds straightforward. In reality, it’s messy.

Factories run on:

- Legacy PLCs with limited interfaces

- Proprietary protocols

- Half-documented control logic written by engineers who retired years ago

Agents should adjust to this environment, rather than expecting a fresh start.

Successful deployments usually involve:

- Shadow modes where agents learn without acting

- Gradual expansion of decision scope

- Close collaboration with controls engineers (not just IT)

- A willingness to accept imperfect data

Also read: AI Native Companies: Born-Agentic vs. Agent-Enhanced Enterprises

Embedded Agents and the Human Operator

There’s an unspoken fear that agents will deskill operators. In practice, the opposite often happens.

When agents handle low-level adjustments, operators spend more time on:

- Diagnosing systemic issues

- Improving changeover procedures

- Coaching less experienced staff

But the technique only works if agents are transparent. Black-box decisions erode trust quickly.

Effective agents explain themselves:

- Why was the speed reduced?

- What signals triggered concern

- How confident the recommendation is

The explanations should be concise and not overly detailed. The level of detail should be sufficient to ensure that humans remain informed.

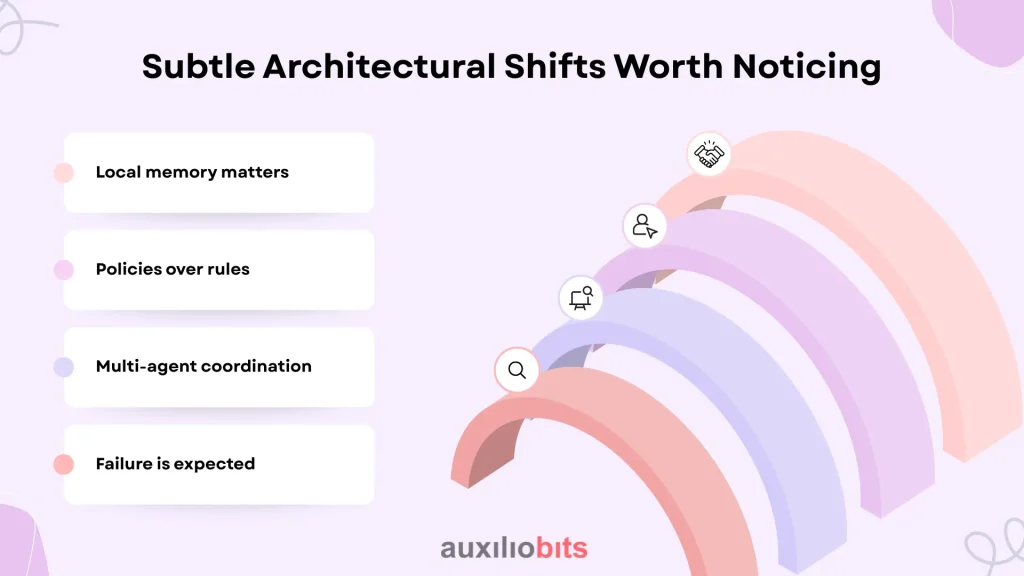

Subtle Architectural Shifts Worth Noticing

A few patterns are emerging across smart factories adopting embedded agents:

Local memory matters

Agents maintain short-term operational memory distinct from enterprise historians. What happened five minutes ago can be more relevant than what happened last quarter.

Policies over rules

Instead of hard-coded logic, agents operate under policy constraints: limits, priorities, risk thresholds.

Multi-agent coordination

Individual agents handle local optimization. Higher-level agents arbitrate conflicts. Not always cleanly, but better than centralized control.

Failure is expected

Agents degrade gracefully. When uncertain, they defer. This humility is designed, not accidental.

Why This Shift Is Hard to Reverse

Once factories experience localized intelligence, going back feels regressive. It’s like removing cruise control after getting used to it. You can still drive. You just work harder.

Embedded agents don’t make factories autonomous overnight. They make them more aware. And awareness, in complex systems, compounds.

You will notice a decrease in midnight calls. It can be observed in control rooms that are more tranquil. Operators are showing a slight increase in trust in systems and a decrease in their confrontation with them.

Is it perfect? No. Does it introduce new failure modes? Absolutely. But manufacturing has always been about managing trade-offs, not eliminating them.

Embedded agents simply move some of those trade-offs closer to where work actually happens. And that, quietly, is changing how smart factories really work.