Key Takeaways

- Agentic automation is a journey, not a switch. Manufacturing enterprises advance from Assist → Co-Pilot → Autonomous, each stage building trust, process clarity, and measurable impact.

- KPIs must evolve with phases. Early stages focus on effort reduction and exception quality, co-pilot stage emphasizes recommendation acceptance and trust, and autonomy measures outcomes, reversals, and business impact.

- Trust is the hidden currency. Co-pilot and autonomous systems succeed only when humans understand and trust recommendations, making explainability and feedback loops critical.

- Autonomy is bounded, not universal. Machines should own high-frequency, low-risk, reversible decisions; strategic and high-stakes decisions remain human-led.

- Roadmaps fail due to incentives, not technology. Misaligned KPIs or conflicting objectives can derail agentic adoption faster than poor algorithms ever could.

Manufacturing leaders are being told—loudly—that “agentic automation” is the next leap after RPA and traditional hyperautomation. That’s mostly true. What’s missing from many of those conversations is how you actually get there without blowing up operations, trust, or governance.

Most factories don’t jump from spreadsheets to self-directing AI agents overnight. They move in phases. Sometimes intentionally. Often accidentally.

After working with manufacturing enterprises across procurement, production planning, finance, and quality operations, a pattern shows up again and again: successful programs follow a three-phase evolution—Assist → Co-Pilot → Autonomous. This pattern emerges not as a marketing funnel, but rather as an operational necessity.

This article breaks down what each phase really looks like on the plant floor and in back offices, where it tends to fail, and—most importantly—how to define KPIs that actually signal readiness to move forward.

Also read: Automation as a Strategic Weapon in Manufacturing M&A

Why “Agentic” Changes the Roadmap Itself

Traditional automation roadmaps were linear. Identify the process. Automate steps. Scale bots. Optimize exceptions later.

Agentic automation breaks that logic.

Once you introduce systems that can:

- observe outcomes,

- reason across context,

- decide next actions,

- and learn from feedback,

…the roadmap stops being about coverage and starts being about decision authority.

The core question becomes: Which decisions are machines allowed to assist with, recommend on, or fully execute—and under what constraints?

That’s why a phase-wise roadmap matters. Not because it sounds neat in a slide deck, but because manufacturing is allergic to uncontrolled decision-making. For good reason.

Phase 1: Assist — Automating Effort Without Owning Decisions

This is where almost every manufacturing organization already is, whether they call it agentic or not.

What “Assist” Means

Assistive automation focuses on removing human effort, not judgment.

Think:

- Data collection

- Validation

- Reconciliation

- Cross-system handoffs

- Exception surfacing (not resolution)

The system supports humans. It does not argue with them.

In manufacturing, this phase often appears in places like:

- Purchase requisition validation before ERP entry

- Invoice matching across GRN, PO, and supplier invoices

- Production reporting pulled from MES and normalized for planners

- Supplier onboarding document checks

A real example: A global automotive supplier automated vendor invoice pre-checks across three ERPs. Bots extracted invoices, matched line items, flagged mismatches, and attached context—but accountants still decided whether to post or block. No AI “decisions,” just faster cognition.

That’s Assist.

Where Teams Go Wrong Here

The common mistake is overselling intelligence too early.

You’ll hear things like: “The system flags anomalies using AI.”

If all it’s doing is rule-based thresholds plus OCR confidence scoring, that’s fine. Calling it decision intelligence isn’t.

Another failure mode: automating around bad processes. If approval chains are broken or data ownership is fuzzy, Assist just makes the mess faster.

KPIs That Actually Matter in Assist Phase

Forget vanity metrics like “number of bots.”

What you want to track instead:

% decrease in human data entry or reconciliation effort

- % decrease in human data entry or reconciliation effort

Cycle time compression

- Time from input to readiness-for-decision (not final approval)

Exception quality

- Ratio of valid vs false-positive flags

Data completeness

- Missing-field rates before vs after automation

If exception quality is poor, don’t move forward. Co-pilot systems amplify bad signals.

Phase 2: Co-Pilot — Shared Decisions, Human in the Loop

This is where agentic concepts start to matter.

The system doesn’t just surface issues. It suggests actions.

What Co-Pilot Looks Like on the Ground

In manufacturing, co-pilot systems usually show up in:

- Procurement approvals with risk/context scoring

- Production planning adjustments during disruptions

- Supplier risk monitoring with recommended interventions

- Quality deviations with suggested containment steps

One electronics manufacturer implemented a co-pilot for indirect procurement.

When requisitions came in, the system:

- assessed supplier reliability,

- checked contract compliance,

- evaluated historical pricing,

- and recommended approve / route / renegotiate.

Buyers could override. Many did, initially. Over time, overrides dropped—not because of mandates, but because the suggestions were usually right.

That’s the quiet success pattern.

The Real Design Challenge: Trust Calibration

This phase fails when:

- systems feel like black boxes, or

- recommendations conflict with tribal knowledge without explanation.

Manufacturing professionals don’t mind automation. They hate unjustified automation.

Effective co-pilots:

- show reasoning trails,

- expose confidence levels,

- learn from overrides instead of ignoring them.

And yes, this slows deployment. It’s still faster than repairing trust later.

KPIs That Signal Co-Pilot Maturity

This phase needs different metrics. Speed alone is no longer enough.

Look for:

Recommendation acceptance rate

% of system suggestions followed without override

Override quality

- When humans override, are outcomes better or worse?

Decision latency

- Time from recommendation to human action

Risk-adjusted outcomes

- Fewer compliance breaches, fewer downstream corrections

User trust indicators

- Adoption without enforcement (harder to measure, but visible)

A warning sign: If acceptance rates are high because people blindly click approve, you’ve skipped governance. That catches up later.

Phase 3: Autonomous — Machines Own Bounded Decisions

Fully autonomous systems in manufacturing are rare—and should be.

Autonomy does not mean “AI does whatever it wants.” It means predefined decision rights within strict boundaries.

What Autonomy Looks Like

Autonomous agentic systems typically own:

- Low-risk, high-frequency decisions

- Actions with reversible impact

- Scenarios with strong historical patterns

Examples seen in practice:

- Auto-releasing purchase orders within price/volume tolerances

- Rescheduling production within predefined buffers

- Blocking invoices that clearly violate contracts

- Triggering supplier audits when risk scores cross thresholds

Notice what’s missing: strategic sourcing, major capex, plant shutdown decisions. Those stay human.

Why Many Organizations Stall Here

Two reasons:

- Governance fear – Who’s accountable when an agent makes a bad call?

- Data reality – Autonomy exposes every inconsistency you tolerated before.

Agentic systems don’t fail quietly. They surface uncomfortable truths about master data, policies, and incentives.

Some teams retreat back to co-pilot mode. That’s not always wrong. Autonomy is optional. Readiness is not universal.

KPIs That Define Autonomous Readiness

Autonomy demands outcome-based measurement.

Key indicators include:

Decision accuracy

- Autonomous actions vs optimal historical outcomes

Reversal rate

- How often humans roll back agent decisions

Business impact

- Cost leakage avoided, downtime reduced, working capital improved

Compliance integrity

- Zero tolerance breaches

System learning rate

- Improvement over time without rule explosion

When autonomous systems run without constant firefighting, that’s success.

How Phases Overlap

In reality, manufacturing organizations run all three phases simultaneously.

- Assistive automation in finance

- Co-pilots in procurement

- Autonomous agents in inventory replenishment

Trying to “graduate” the entire enterprise at once is a recipe for frustration.

A better mental model:

- Processes move through phases independently

- Decision types, not departments, define autonomy

This is where many roadmaps fail—by being too organizational and not decision-centric.

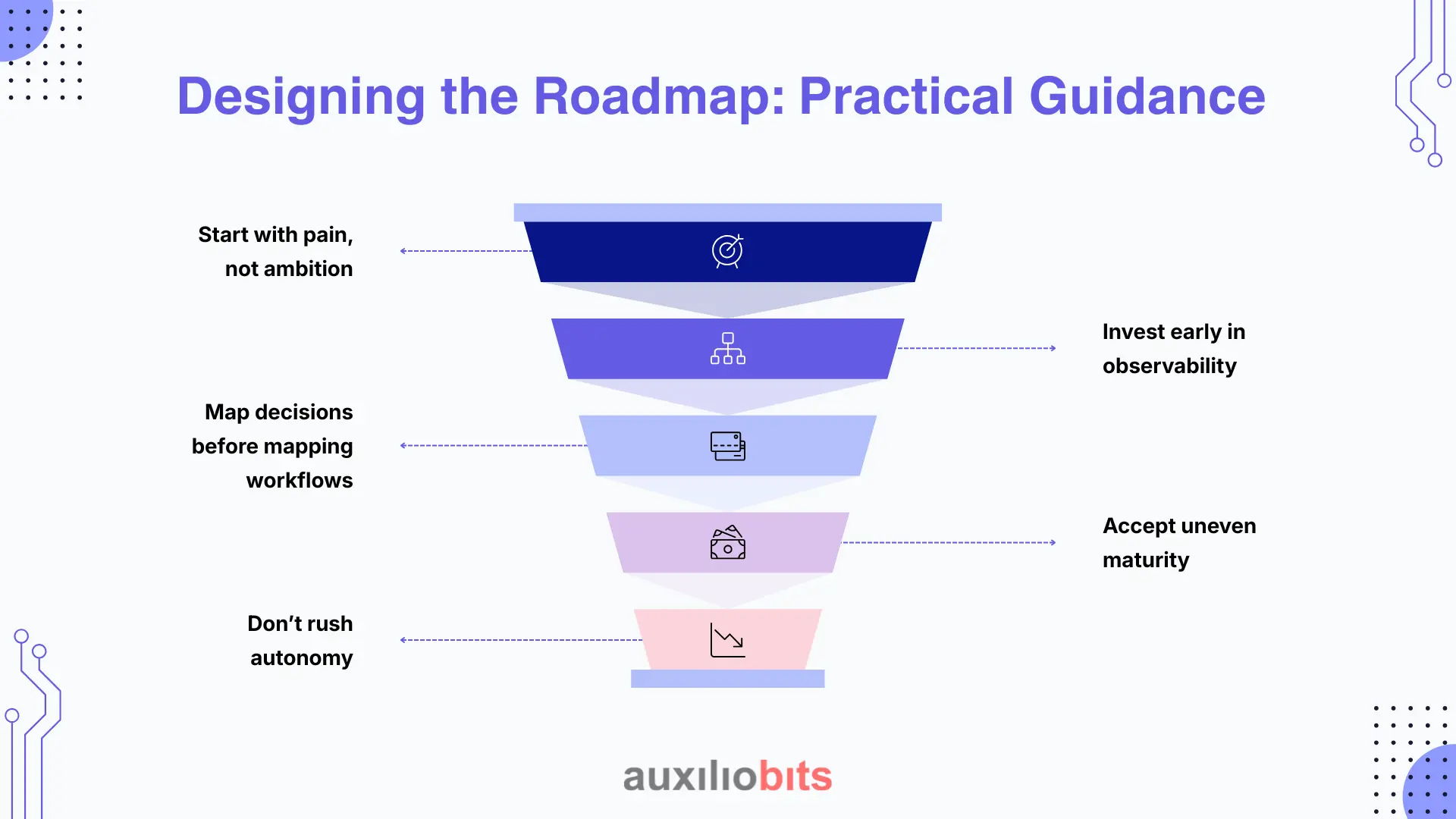

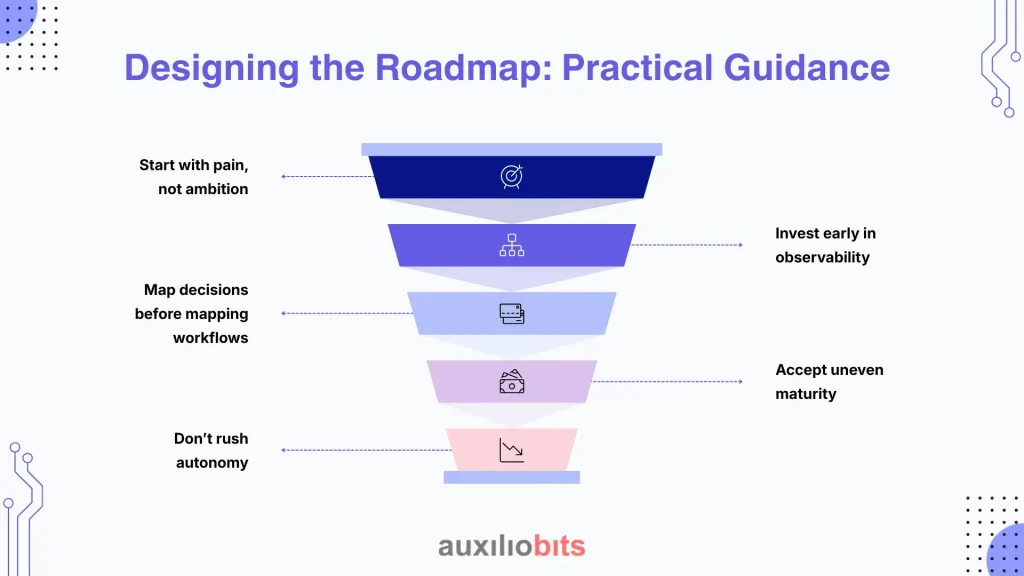

Designing the Roadmap: Practical Guidance

A few hard-earned lessons worth sharing:

- Start with pain, not ambition: The best agentic use cases come from chronic operational friction, not innovation labs.

- Map decisions before mapping workflows; Who decides what today? Under which constraints? That clarity saves months.

- Don’t rush autonomy: Assist and co-pilot phases are not stepping stones to “get through.” They are value stages.

- Invest early in observability: If you can’t explain why a system suggested something, autonomy is off the table.

- Accept uneven maturity: A plant in Mexico and a plant in Germany will not evolve at the same pace. That’s fine.

Where Agentic Roadmaps Quietly Break

A candid aside: The biggest risk is not technology. It’s misaligned incentives.

If planners are measured on schedule adherence but agents optimize inventory turns, you’ll see conflict. If procurement bonuses reward negotiated savings but agents enforce contract compliance, expect resistance.

Agentic systems expose incentive mismatches brutally fast.

Fix those, or the roadmap becomes political theater.

A Final Thought

Agentic automation in manufacturing isn’t about replacing people. That framing is tired and inaccurate.

It’s about redistributing cognitive load—letting machines handle consistency, memory, and speed, while humans focus on judgment, negotiation, and accountability.

The Assist → Co-Pilot → Autonomous roadmap works because it respects how manufacturing actually changes: cautiously, unevenly, and with scars from past “transformations.”

If your roadmap feels slow, it’s probably realistic. If it feels frictionless, something important is being ignored.

And in manufacturing, ignored details always come back—usually at quarter-end.