Key Takeaways

- Temperature deviations are critical signals, not minor fluctuations. Timely recognition and context-aware interpretation are essential to avoid spoilage, regulatory delays, and financial loss.

- Monitoring alone is insufficient; human responders remain crucial. Even the most advanced IoT or AI systems fail without trained personnel who can act decisively.

- Agent archetypes differ in sophistication, cost, and sector fit. Semi-autonomous agents currently offer the strongest balance between automated decision-making and human oversight.

- Trust in data and response infrastructure drives outcomes. Reliable calibration, clear logs, and transparent reporting prevent unnecessary product destruction and regulatory scrutiny.

- Emerging technologies enhance but don’t replace judgment. Predictive AI, blockchain, and smart packaging improve decision-making speed and accuracy—but integration with human expertise is the key differentiator.

Maintaining product quality across temperature-sensitive supply chains is a deceptively challenging task. On paper, the cold chain looks straightforward—refrigerated trucks, insulated packaging, and clear SOPs. In practice, it’s a web of variables that rarely line up neatly. Even a two-degree swing at the wrong time can compromise an entire batch of biologics, erase weeks of research and development, or result in millions of dollars in food spoilage.

That’s why monitoring technology and the way humans or automated agents respond to deviations is not a compliance detail anymore—it’s the core of risk control.

Also read: Agent‑driven supply chain visibility: real‑time tracking, forecasting, and adjustments

Why Deviations Are Never Just “Minor Fluctuations”

Anyone who has worked with frozen APIs, fresh produce, or plasma shipments knows that a graph spike is not a simple data point. It’s a potential root cause investigation waiting in the wings. Consider a shipment of fresh strawberries moving through a mixed regional distribution hub. A one-hour rise from 2°C to 8°C doesn’t just reduce shelf life—it cascades: retailers shorten display durations, consumers sense a shorter “fresh window,” and waste percentages tick upward.

That’s the same story in biopharma, except the losses compound differently. Clinical trial material can’t be re-run in a week like another food harvest. Once integrity is questioned, the chain of custody suffers, regulatory filings get snarled, and trial timelines slip. A single logger alert, if not acted upon, can push an IND submission back by months.

Responding properly requires more than just recording that the variance happened—it demands context around the why. Was there a reefer unit cycling issue? Was the packaging underspecified for the lane? Did the driver bypass a pre-trip check? Without framing variances in context, even the most advanced sensors become little more than tattletales.

The Rise of Real-Time Monitoring Agents

Ten years ago, most cold chain monitoring was passive. Stick a data logger inside a box, ship it, and download results on arrival. The industry tolerated this reactive approach. That tolerance is mostly gone.

Today’s monitoring “agents” aren’t single-use loggers—they are networked devices, increasingly connected through IoT platforms, cellular modules, satellite links, and blockchain-backed custody ledgers. They do more than ping temperatures. They interpret thresholds, differentiate minor oscillations from genuine breaches, and in some cases, trigger escalation protocols automatically.

In a pharmaceutical context, companies like DHL and UPS Healthcare have implemented tiered monitoring services where AI-driven platforms continuously triage events. Instead of a human opening an Excel sheet post-shipment, operators get real-time alerts with automated recommendations: reroute the truck to the nearest qualified facility, initiate a dry ice replenishment order, or trigger quarantine protocols mid-shipment.

It’s not all technology, though. Behind these dashboards sit human operations teams that must decide—quickly—when an alert is truly actionable versus when it’s harmless noise. That judgment piece is easy to underestimate, and it is often where failures still occur.

The Human Element: Responders as the Critical Agents

Technology tends to hog the spotlight, but mismanaged human response is the most common weak link. Consider:

- A frozen plasma shipment sets off a deviation alert during airport tarmac handling. An operations team dismisses the alarm, thinking exposure was too brief to matter. Hours later, the receiving lab refuses acceptance, citing chain-of-custody ambiguity.

- A produce distributor receives early warnings of reefer malfunction but delays response, hoping the container will “stabilize.” By the time a technician intervenes, pulp temperatures have exceeded the safety band for too long.

In both cases, there was monitoring. But agents—human decision makers—failed to calibrate urgency to risk. That calibration requires domain knowledge, training, and sometimes even organizational culture that says “intervene now and deal with cost later” rather than “stretch thresholds to save money.”

There have been temperature excursions treated as acceptable “just because the product still looked fine.” That mindset is dangerous. Regulators don’t judge safety with eyeballs, and neither should operators.

Different Agent Archetypes

It helps to categorize monitoring and response into archetypes, each with distinct strengths and vulnerabilities.

- Passive Watchers: Single-use loggers that passively collect data. Cheap, but useless for real-time rescue.

- Active Devices without Triggers: GPS + temperature sensors transmitting continuously, but still reliant on human review. These are effective only if paired with disciplined follow-up.

- Semi-Autonomous Agents: Devices and platforms that not only send alarms but also rank severity and propose interventions. The human-in-the-loop model is strongest here.

- Autonomous Escalators: Very new, these can, for example, auto-initiate a courier redirection to specialized storage without waiting for approval. Their adoption is still tentative, mainly because of liability concerns.

Different sectors lean differently. Food logistics often sticks to cheaper semi-active loggers due to margin sensitivity. Biologics lean hard toward semi-autonomous platforms where intervention ROI is obvious. Blood supply chains in humanitarian settings sometimes adopt autonomous models, because any lost unit is irrevocable.

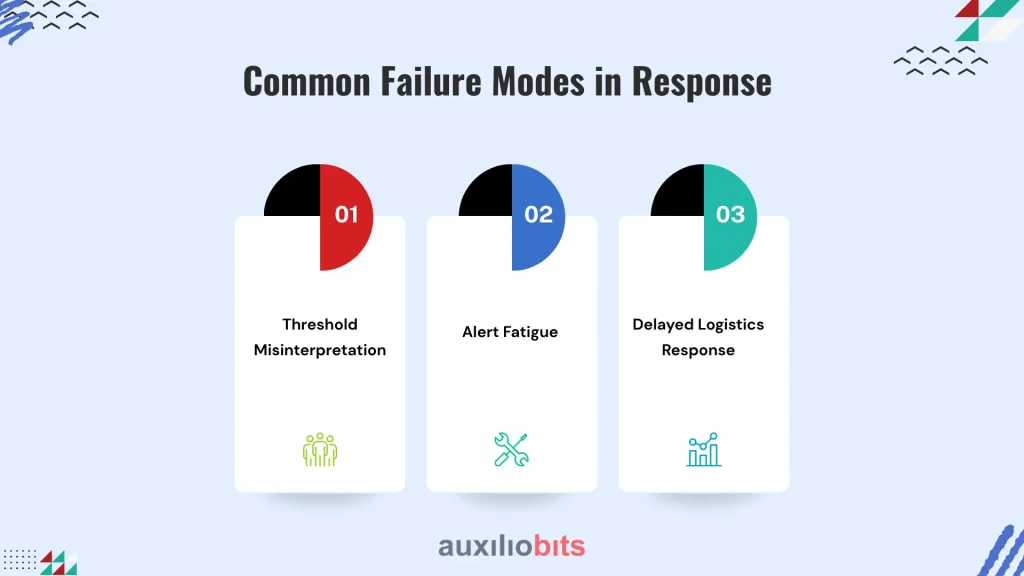

Common Failure Modes in Response

Temperature excursions are often detected. But whether the product is saved depends on how agents—human or machine—respond. Three failure modes recur:

1. Threshold Misinterpretation

Many organizations set generic 2–8°C alarms across product categories. In reality, some biologics tolerate brief higher ranges, others degrade fast outside narrower bands. Too broad alarms lead to overreaction and wasted product. Too lax alarms mean silent degradation.

2. Alert Fatigue

Continuous monitoring platforms can create a flood of notifications. If every fluctuation pings a handler’s phone, sooner or later, alerts get ignored. This is where AI ranking of severity is not optional—it’s survival.

3. Delayed Logistics Response

Even when alerts are genuine and identified, operational inertia kills outcomes. If a dry ice replenishment service takes six hours to dispatch, the alert itself adds little value. Monitoring without a service infrastructure to act is half a solution.

Case Example: Insulin Shipments

Insulin supply chains are often cited as textbook cold chain challenges. One national program struggled to maintain 2–8°C conditions while distributing vials from centralized warehouses to remote clinics. Data loggers revealed regular two-hour spikes during last-mile motorcycle deliveries.

Instead of merely cataloging these deviations, the program deployed solar-powered mini-fridges in key clinics and shifted response protocols: if deviations were flagged in transit, couriers could bypass intermediate storage and deliver directly to the nearest equipped site. Monitoring agents worked not just as sensors but as decision guides. The result wasn’t flawless—there were still losses—but patient complaints about spoiled insulin dropped significantly. It’s proof that monitoring isn’t enough; coupling detection with an empowered response infrastructure moves the needle.

Why Trust Still Matters

All the automation in the world does little if downstream stakeholders don’t trust the monitoring data. Retailers, regulators, and clinicians frequently ask: Can I rely on what your sensors reported, or should I perform my own stability tests?

Trust gaps usually open when:

- Devices come from unvalidated suppliers.

- Calibration logs are missing or outdated.

- Alarm histories suggest inconsistent thresholds.

- Reporting feels opaque, with only aggregates and no raw logs.

Seasoned professionals know regulators rarely forgive missing metadata. A batch flagged as “borderline” is more likely to be destroyed if confidence in data capture is weak. This is why companies that invest in the reliability of monitoring practices often win the longer game, even when upfront device costs are higher.

Emerging Trends Changing Agent Roles

A few developments are reshaping how monitoring agents function in the next five years:

- AI-driven predictive variance detection: Systems that forecast risk hours before an excursion by analyzing ambient weather, transit delays, or refrigerant performance.

- Decentralized ledgers (blockchain): Not hype in this case. Immutable custody logs reduce disputes and secure confidence across trading partners, especially cross-border.

- Smart packaging: Labels that change visually when thresholds are breached. These aren’t high-tech IoT, but sometimes that low-cost, human-observable method is what works.

- Dynamic response networks: Instead of static escalation workflows, platforms choose intervention partners dynamically—dispatching drones, Uber-like cold chain couriers, or local pharmacies as impromptu waypoints.

Critically, not every sector will adopt all of these. Biotechnology shipments may integrate blockchain and AI early. Fresh fish imports might favor visual smart tags over complex IoT to keep economics viable.

Subtleties in Agent Decision-Making

A nuance often overlooked: not all variances are equal. A steady climb over hours carries different risk chemistry than a five-minute spike. Agents that ignore thermal kinetics—the way heat energy interacts with product type—inevitably misjudge impact.

For example, frozen meat blocks can tolerate a brief surface rise because of thermal inertia. Vaccines in vials cannot. Agents that treat both deviations equally introduce waste on one side and risk on the other.

Designing agents, therefore, isn’t just choosing thresholds. It requires product-specific stability profiles feeding into algorithms. That’s where partnerships between suppliers and monitoring tech firms must deepen. Tech without product science is blunt.

The Takeaway

Cold chain monitoring has moved past data collection. The industry’s challenge is now about how agents—both human and machine—interpret and act on variances in real time. Integration matters more than sophistication. Without trained responders, even predictive AI stalls. Without credible data streams, human responders hesitate. Without rapid escalation access, alerts expire into irrelevance.

The strongest setups mix layers: simple visual indicators for frontline handlers, real-time IoT feeds for operations teams, and product-specific stability logic guiding escalation playbooks. Organizations that marry speed with nuance gain more than compliance—they reduce waste, protect brand trust, and sometimes even differentiate commercially in crowded markets.

Cold chains will never behave perfectly; fluctuations are inevitable. The real question is whether monitoring and response agents are designed to treat those variances as noise to be ignored or as signals to be engaged. Too many supply chains still default to the first. The leaders—the ones you hear about when insulin reaches rural clinics intact or clinical trial material passes audits cleanly—have chosen the second.