Key Takeaways

- Autonomous scheduling agents bridge the gap between ERP and shop-floor systems, dynamically adjusting schedules in real time to account for machine downtime, workforce availability, and material delays.

- Traditional ERP scheduling is inherently static; it relies on snapshots of production and cannot adapt to real-world variability, often leading planners to spend more time reacting than optimizing.

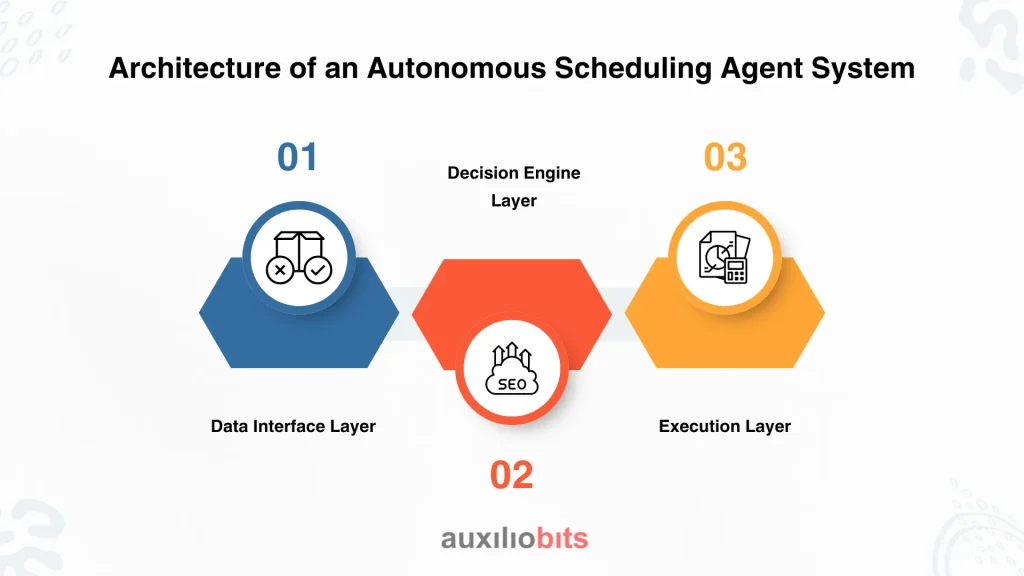

- Architecture matters: A robust system combines a data interface layer, a decision engine using AI and predictive analytics, and an execution layer that communicates adjustments to operators and machines.

- Human oversight is crucial: Agents are most effective when paired with planners, ensuring that decisions are practical, explainable, and aligned with strategic priorities.

- Real-world results demonstrate tangible benefits—reduced downtime, optimized materials, higher on-time delivery, and planners freed to focus on strategic decision-making—but success depends on reliable data, integration quality, and organizational buy-in.

In modern manufacturing, the disconnect between enterprise resource planning (ERP) systems and shop-floor operations is more than just a technical inconvenience—it’s a recurring productivity sink. Planners meticulously craft schedules in ERP platforms, but by the time instructions reach the production floor, delays, machine downtime, or material shortages have often invalidated them. The result? Over time, there have been rushed work, unhappy clients, and wasted resources. Enter autonomous scheduling agents—a class of intelligent software that doesn’t just bridge systems but dynamically adapts schedules, making real-time decisions that were previously the domain of seasoned human planners.

Also read: Conversational agents as service: combining LLMs, NVidia GPU clouds, and Azure/AWS endpoints

Why Traditional Scheduling Often Fails

ERP systems are inherently structured for data centralization and transactional accuracy. They excel at tracking orders, inventory, and procurement. Yet when it comes to production scheduling, they’re essentially static. A planner inputs a sequence of operations, allocates resources, and assumes machines and personnel will follow the plan. Reality, of course, has other ideas:

- Unexpected machine downtime disrupts the sequence.

- Operators call in sick or are diverted to urgent tasks.

- Raw materials arrive late or in insufficient quantities.

- Multi-site coordination introduces lag that ERP rarely accounts for dynamically.

ERP software does include scheduling modules, often using heuristic or optimization algorithms. But these approaches are inherently brittle: they rely on snapshots of the system state that can become outdated within minutes. As a result, production planners often spend more time reacting than planning.

Enter Autonomous Scheduling Agents

Autonomous scheduling agents operate differently. Think of them as digital coordinators embedded both in the ERP and on the shop floor. Unlike traditional scheduling systems, these agents:

- Continuously monitor the status of machines, workforce availability, material flow, and order priorities.

- Identify conflicts and bottlenecks proactively rather than reactively.

- Adjust production sequences in real time, balancing efficiency, throughput, and resource utilization.

An effective agent doesn’t simply “follow rules.” It reasons with context: if a critical machine goes down, should the agent swap in a parallel production line? Can it prioritize high-margin orders without violating contractual deadlines? How does a delay in one department ripple through dependent processes? These are complex trade-offs—ones that autonomous agents are increasingly capable of managing.

Architecture of an Autonomous Scheduling Agent System

At a high level, a robust system integrates three layers:

1. Data Interface Layer

- Connects ERP, MES (Manufacturing Execution Systems), and shop-floor sensors.

- Provides real-time visibility of machine status, order progress, and inventory.

- Handles disparate protocols and formats—because in reality, few factories run a uniform tech stack.

2. Decision Engine Layer

- Applies AI techniques like constraint programming, reinforcement learning, or multi-agent negotiation to generate adaptive schedules.

- Evaluates trade-offs in real time: prioritizing throughput versus minimizing setup times, for example.

- Incorporates predictive insights such as expected machine failures or workforce bottlenecks.

3. Execution Layer

- Communicates revised schedules back to shop-floor operators or machines.

- Logs decisions for audit, compliance, and continuous learning.

- Ensures overrides are safe, transparent, and reversible if needed.

Some advanced deployments even use multi-agent systems, where different agents specialize in resource allocation, maintenance prediction, or order sequencing. These agents communicate asynchronously, negotiating priorities as they emerge—a method that mirrors human planning meetings but happens orders of magnitude faster and with higher accuracy.

Real-World Impact

Companies experimenting with autonomous scheduling agents report tangible benefits, though adoption is not without nuance.

- Reduced downtime and smoother throughput: A European automotive supplier implemented agents that dynamically reassigned jobs from an overheated CNC machine to an idle parallel line. They reported a 12% reduction in unplanned downtime and a measurable increase in on-time delivery.

- Material optimization: Agents tracking just-in-time inventory allowed a large electronics manufacturer to reduce work-in-progress inventory by 18%, freeing warehouse space and reducing holding costs.

- Human planner augmentation: Rather than replacing planners, autonomous agents often act as sophisticated assistants, highlighting conflicts, suggesting optimizations, and freeing planners to focus on strategic decisions.

However, results depend heavily on contextual integration. Factories with unreliable IoT sensors or inconsistent ERP data often see diminished benefits. Agents can only act on the information they have, and poor data quality can lead to counterproductive decisions, such as rescheduling a machine that was actually operating fine.

Challenges and Pitfalls

Even the most sophisticated agent systems face hurdles. Some recurring themes include:

- Resistance from personnel: Operators may mistrust decisions from an opaque algorithm, especially if they contradict long-established routines. Change management and transparency are crucial.

- ERP rigidity: Many ERP platforms were not designed for real-time control. Integrating a dynamic agent requires robust APIs and often custom middleware.

- Complexity of trade-offs: Optimizing for one metric—say, throughput—can inadvertently reduce quality or increase energy consumption. Agents must balance multiple objectives, sometimes with conflicting priorities.

- Unexpected scenarios: Agents can struggle with truly novel events, such as a sudden raw material shortage that has no historical precedent. Human oversight remains critical.

Strategies for Effective Deployment

Experience suggests that successful deployments share several common approaches:

- Phased integration: Start with a limited scope—perhaps a single production line—before scaling to the entire facility. This allows fine-tuning and builds trust.

- Hybrid decision-making: Combine autonomous scheduling with human oversight. Let agents propose schedules and planners validate or adjust them.

- Data quality improvement: Accurate, high-frequency data from machines, operators, and inventory systems is non-negotiable. Agents are only as smart as the data they see.

- Transparent logging and explainability: Planners and managers need to understand why an agent made a certain decision. Explainable AI techniques can prevent mistrust and facilitate continuous improvement.

Emerging Trends

Some fascinating trends are shaping the next wave of autonomous scheduling:

- Predictive and prescriptive analytics: Agents increasingly anticipate equipment failures, material shortages, or workforce issues before they occur. Some even simulate multiple “what-if” scenarios to choose the least disruptive course of action.

- Cross-facility orchestration: Agents can now optimize not just a single plant, but entire supply networks, coordinating multiple sites and suppliers dynamically.

- Integration with digital twins: Combining scheduling agents with digital twin models allows factories to simulate production outcomes virtually before executing them, refining decisions in a risk-free environment.

- Agentic negotiation: Multi-agent systems negotiate priorities among themselves, balancing competing objectives across production, maintenance, and logistics. This mirrors human problem-solving but can operate continuously and faster than any human team.

Case Example: Automotive Tier-1 Supplier

Consider a Tier-1 automotive parts supplier managing multiple production lines across three plants. Historically, planners manually reconciled ERP schedules with MES data every morning—a process prone to errors, delays, and repeated adjustments. After implementing autonomous scheduling agents:

- Job sequences were adjusted in real time, responding to machine availability, workforce schedules, and urgent order requirements.

- Maintenance teams received automated alerts when predicted delays threatened deadlines, allowing preemptive intervention.

- The company reduced overtime by 15% and improved on-time delivery by 9%, while planners could focus on strategic capacity expansion rather than daily firefighting.

Interestingly, not all improvements came from algorithms. A key success factor was trust-building: agents explained each schedule change through dashboards and natural language summaries, which made planners comfortable adopting suggestions.

A Caution

It’s tempting to see autonomous scheduling agents as a silver bullet. But, like any tool, they amplify strengths and weaknesses. Factories with messy, inconsistent data will expose flaws quickly. Over-reliance on autonomous agents without human oversight can lead to decisions that are technically optimized but practically untenable. And organizational culture often matters more than technology: without buy-in from shop-floor personnel, even the smartest agent will be underutilized or ignored.

Looking Forward

The convergence of AI, IoT, and advanced scheduling algorithms suggests that autonomous agents will become increasingly central to manufacturing operations. Yet their role will not be purely prescriptive. Instead, they function best as partners: continuously analyzing, adjusting, and learning, while humans provide strategic oversight, judgment, and contextual intuition.

It is this partnership—agents handling repetitive, high-frequency scheduling decisions, humans focusing on exceptions, strategy, and relationship management—that defines the next era of production planning. The result is not only more efficient schedules but also a more resilient and adaptive production ecosystem, capable of responding to uncertainties that would overwhelm traditional ERP-based planning.