Key Takeaways

- Manual tracking methods are outdated and create delays, errors, and inefficiencies, leading to higher costs and unhappy customers.

- Autonomous agents are intelligent, proactive systems that can make decisions, track containers in real-time, predict delays, and solve issues without constant human input.

- These agents integrate IoT, port systems, weather data, and customs info to provide a clear, live view of container journeys and improve ETA accuracy.

- Problem-solving becomes proactive, with agents detecting disruptions early, diagnosing root causes, and triggering automated fixes or human escalation when needed.

- Businesses adopting autonomous agents in logistics can expect up to a 20% reduction in logistics costs, faster issue resolution, greater visibility, and a stronger competitive edge in global trade.

The way goods move around the world is like a giant, complex puzzle. Every day, countless products travel across oceans and lands to reach us. But this journey isn’t always smooth. Keeping track of shipping containers and fixing problems when they pop up can be a real headache. It often means a lot of manual checks, phone calls, and wasted time.

But what if there was a better way? What if smart computer programs could do all this heavy lifting for us? That’s exactly where autonomous agents come in. These “smart helpers” are changing how we track containers and deal with issues, making the whole shipping process much smoother, clearer, and cheaper. This article will explain how these autonomous agents are making a big difference in the world of logistics.

Also read: Ethical Considerations When Deploying Autonomous Agents

The Old Way of Tracking Containers: Lots of Guesswork

For a long time, figuring out where a container was felt like a treasure hunt. Businesses often used old methods that caused a lot of problems:

Information often came late or was missing completely. This meant companies couldn’t tell exactly where a container was or what was happening to it at any given moment.

When people have to type in data or check things over and over manually, mistakes happen. This could lead to wrong delivery times or even lost shipments.

As more goods move around the world, these old ways just can’t keep up. They slow everything down.

Most of the time, companies only find out about a problem after it has already caused a delay or issue. Then, they’d have to scramble to fix it.

All these problems meant more money spent (like fees for containers sitting too long) and frustrated customers because deliveries were late or unpredictable. For example, a study showed that in 2025, over two-thirds of logistics teams still struggle with slow tracking updates, losing hours each week just trying to find information.

We need a smarter, faster way to manage shipping.

What Are Autonomous Agents? Your New Smart Logistics Team?

So, what exactly are these autonomous agents? Think of them as very smart computer programs that can work on their own, learn things, and make smart choices without constant human help. They’re more than just simple automated tools; they have a deeper “brain” that lets them adjust to new situations.

Here’s what makes them special:

- Work on Their Own: They can do tasks and make decisions without someone telling them what to do every step of the way.

- Take Action: They don’t just wait for orders; they can start doing things based on goals you set or problems they notice.

- React Quickly: They can see what’s happening (by looking at data) and respond right away to changes.

- Can “Talk” to Others: In advanced systems, they can share information and work with other agents or even people.

- Learn and Get Better: Using AI (Artificial Intelligence) and machine learning, they constantly learn from new information, getting smarter and more effective over time.

Imagine having a digital assistant that’s not only smart but can also act independently to solve problems. Experts believe that by 2025, these AI agents will be able to plan, carry out, and change tasks with very little human involvement, making supply chains much smoother.

Autonomous Agents for Tracking Containers: Seeing Everything Clearly

Using autonomous agents to track containers is a huge step forward. It changes tracking from just knowing a few facts to having a complete, smart, and even predictive view of your shipments.

Knowing Where Things Are, All the Time

One of the biggest benefits is that these agents can bring together huge amounts of information from many different places:

Tiny devices placed inside containers send live data about location (GPS), conditions (like temperature or humidity), and even if the container has been shocked. This is super important for goods that need special care, giving you real-time container visibility.

Agents connect directly to port systems to get updates on when containers are loaded, unloaded, or moved through gates.

They can access information directly from shipping companies, like ship schedules and cargo details.

Agents can quickly check customs clearance status and any rules that need to be followed.

They can even look at things like weather patterns, political news, or traffic reports to see if anything might affect a shipment.

By constantly collecting and combining all this different information, autonomous agents create a clear picture of every container’s journey. This means everyone involved can see exactly what’s happening, cutting down on time spent chasing updates.

Predicting Arrival Times More Accurately

Beyond just knowing where a container is, autonomous agents use predictive analytics to give much more accurate estimates of when it will arrive. They look at past data, what’s happening right now, and other factors to guess if there might be delays or if things might go faster. For example:

An agent can predict a delay if a big storm is coming and then update the arrival time.

By watching how busy ports are, agents can see if there might be traffic jams and give new arrival times.

Based on past experiences and current rules, agents can warn you if a shipment might get held up at customs.

This way, businesses can spot problems before they get big, helping them plan better for storage and final delivery. Companies that use real-time tracking can fix shipment problems over three times faster and get 32% fewer complaints from customers.

Automated Paperwork and Rules Checking

Autonomous agents can also handle the boring but important task of creating necessary documents (like customs forms) and making sure all the rules and regulations are followed. This greatly reduces manual work, prevents mistakes, and speeds up the entire shipping process from start to finish.

Fixing Problems with Smart Agents: From Firefighting to Smooth Sailing

One of the most exciting parts about autonomous agents is how they handle problems. Instead of just reacting to issues after they happen, they can find, understand, and even fix problems on their own.

Finding Problems Automatically

Traditionally, finding problems like a delayed container or one with the wrong temperature meant someone had to manually check, or a customer had to complain. But AI-powered autonomous agents constantly watch all the shipping details against what’s expected.

An agent can immediately flag if a container goes off its planned path or is behind schedule.

For sensitive goods, smart sensors send temperature data that agents check in real-time. If the temperature goes too high or too low, an alert is sent right away.

Their smart programs can even spot small, odd patterns that might signal a problem before it gets serious. For example, if a container stays at a stop much longer than it usually does.

This automatic problem-finding means nothing gets missed, and everyone who needs to know gets an alert right away.

Smartly Figuring Out Why Problems Happen

Once a problem is found, an autonomous agent can start figuring out why it happened. Instead of just saying “there’s a problem,” the agent tries to understand the cause.

- It can compare the problem with other information: Was there a strike at the port? Bad weather? A computer issue at customs?

- It can look at past cases to see if similar problems had specific reasons.

- The agent can also tell the difference between small issues that will probably fix themselves and big problems that need immediate attention.

This helps provide useful information so people know what to do next.

Quick Solutions and Updates

The true power of autonomous agents in fixing problems is their ability to start solving them and telling people what’s happening right away. Based on the problem and why it happened, agents can:

For common issues, agents can begin pre-planned actions. For example, if a delay is found, the agent could automatically find a new route or contact a different shipping company if possible.

Key people (like the sender, the receiver, or the shipping team) can get automatic, personalized messages by email, text, or on their tracking screens. These messages don’t just say there’s a problem; they also give a new estimated arrival time or suggest what to do next. This makes the supply chain more transparent and builds trust with customers.

For very complex problems that need a person’s judgment, the agent can send the issue to the right human expert. The agent gives them all the important information and an initial analysis, which helps people respond much faster.

This changes how problems are handled, from being a stressful, reactive mess to a smooth, smart, and mostly automatic process. It means shipping teams can fix issues faster and spend more time helping customers.

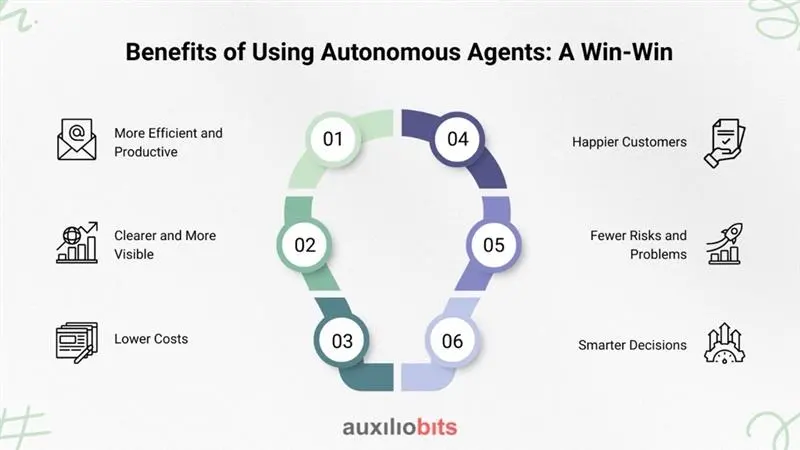

Benefits of Using Autonomous Agents: A Win-Win

Bringing autonomous agents into container tracking and problem-solving offers many great advantages for businesses:

- More Efficient and Productive: Automating daily tasks and fixing problems before they get big means people can spend their time on more important things, like planning and building customer relationships.

- Clearer and More Visible: Knowing exactly what’s happening with every shipment, from start to finish, creates a sense of trust among everyone involved.

- Lower Costs: Fewer delays, fewer mistakes, better routes, and avoiding extra fees all save money. Studies suggest that using AI in supply chains could cut logistics costs by 5 to 20 percent.

- Happier Customers: Accurate delivery times, proactive updates about delays, and faster problem-solving lead to more satisfied and loyal customers.

- Fewer Risks and Problems: Being able to predict and quickly respond to things like bad weather or busy ports makes the supply chain much stronger and more reliable.

- Smarter Decisions: The rich, real-time information gathered and analyzed by agents gives valuable insights for making better decisions and constantly improving the process.

All these benefits together help businesses handle the challenges of global trade with more speed and confidence. They turn logistics from something that just costs money into something that gives a real advantage over competitors.

What’s Next and What Are the Challenges?

- Keeping Data Safe: Protecting sensitive shipping information is extremely important.

- Connecting with Old Systems: Many companies still use older computer systems, which can make it hard to connect them smoothly with new agent technology.

- Starting Costs: The initial cost to develop or buy these advanced agent systems can be high.

- New Rules: Governments are still figuring out rules for AI and data use in shipping, which companies will need to follow.

- Working with People: It’s important to design systems where people can easily work with and manage these autonomous agents.

Despite these challenges, the future of autonomous agents in logistics looks very bright. We can expect them to become even smarter in how they learn, to be used in more parts of the supply chain, and to connect perfectly with other new technologies like blockchain for even more trustworthy tracking data. We’ll also need to think about ethical questions, like how this technology affects jobs.

Conclusion

The old ways of manually tracking containers and fixing problems are quickly fading away. Autonomous agents are not just another piece of technology; they are a major change in how we think about and manage global shipping. By giving us unmatched real-time visibility, smart predictions, and proactive problem-solving, these intelligent systems are leading to amazing levels of efficiency, clarity, and strength in the supply chain.

For any business involved in global trade, using autonomous agents is no longer just an option; it’s a must-have to stay competitive and build the strong, future-ready supply chains that the world needs. The journey towards a fully self-running and self-improving supply chain has just begun, and its powerful impact will keep changing industries worldwide.