Key Takeaways

- Issues like handwriting mistakes, delayed responses, and audit difficulties make traditional systems inefficient and risky for modern factories.

- With sensors, digital forms, and dashboards, manufacturers gain instant visibility into quality performance and can act before issues escalate.

- Digital systems reduce paperwork, streamline audits, and ensure regulatory compliance through precise tracking and timestamping.

- Technologies like QMS platforms, IIoT sensors, and predictive analytics help detect trends and continuously improve operations.

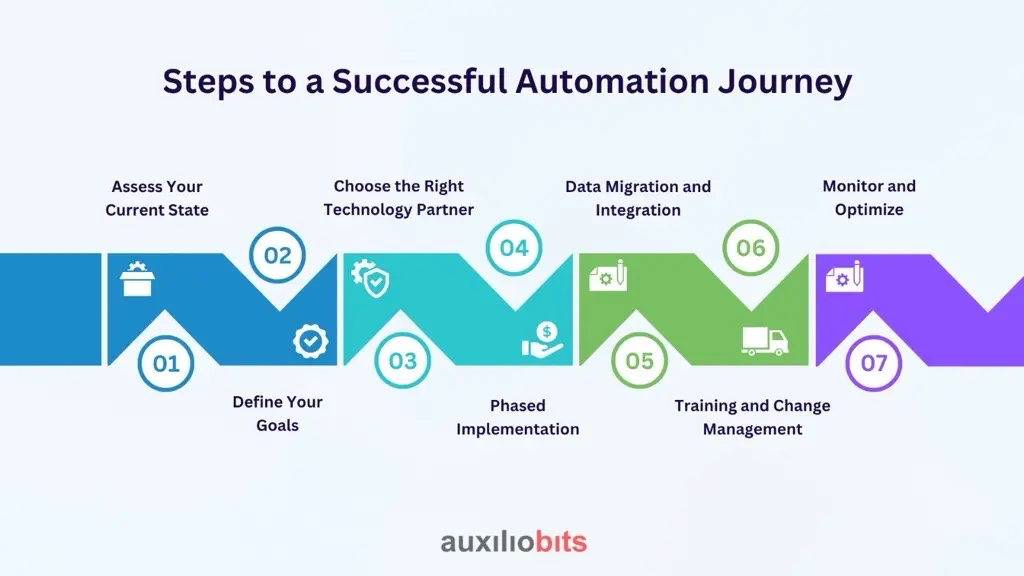

- It starts with assessing the current system, choosing the right tech partner, training staff, and scaling gradually with a focus on long-term optimization.

In the manufacturing sector, everyone wants to make great products efficiently. A big part of this is quality control (QC). For a long time, factories have kept detailed records, or “logs,” of every check, test, and issue. These logs are super important for making sure everything is up to par. However, relying on old-fashioned, manual ways to keep these logs is starting to cause problems instead of solving them.

Now, things are changing. Automating quality control logs isn’t just about putting paper forms onto a computer. Factories have changed their strategies that help them manage, control, and use details related to the quality. It turns a system that detects a problem, and gives an instant solution. This way, managers get real-time details through which they ensure that their company is getting better with time.

This guide will show you how powerful automated QC logs can be. We’ll look at their many benefits, the technologies that make them possible, and what you need to think about to make a successful switch.

Also read: Building a Roadmap for Agentic Automation in Manufacturing

Why Quality Control Matters So Much: It’s More Than Just Rules?

Before we talk about automation, let’s remember why good quality control is so critical. QC isn’t just about following rules; it’s the very foundation of a company’s good name. Every product you make shows how committed you are to excellence.

Manual QC logs, even if they worked okay in the past, often lead to human mistakes. Untidy handwriting, typing mistakes, bad reporting, etc, are some of the most common challenges. These errors can give rise to severe issues if an action is not taken immediately. Some of these problems are listed below:

Slow to Find Problems:

If data isn’t available right away or is hard to find, spotting trends or single defects takes too long. This as an outcome provides slow responses. Additionally, the quality issues become common.

Hard to Figure Out Why Things Went Wrong:

Without complete, easy-to-access data, finding the real reason for a defect is like challenging. This stops you from finding an instant solution. Also, there are chances that the same problem can occur again. This may make it difficult for the manager to handle things properly.

Risks with Rules:

In industries with strict rules, incomplete or wrong logs can cause serious rule-breaking, big fines, and lasting damage to trust.

No Clear Path to Improvement:

Piles of paper data don’t give you much useful information. You miss trends, patterns go unnoticed, and opportunities to make your processes better are lost.

The problems with manual systems aren’t just about being slow; they stop companies from reaching top-notch operations and staying competitive in today’s demanding market.

The Big Benefits of Automation: A Smarter Way to Work

Automating quality control logs offers many benefits that fix the problems with old methods. It moves manufacturing operations to a new level of efficiency and accuracy.

1. Better Data Accuracy and Reliability

Automation cuts down on the most common human errors. Data is collected right where it happens, often using smart sensors, digital forms, or direct links to testing machines. This means:

- No More Typing Mistakes: You don’t have to retype data from paper to computer systems.

- Standard Data: All entries follow the same rules, making sure everything is consistent and clear.

- Checks in Real-Time: Systems can be set up to check data as it’s entered, instantly flagging anything that’s not right.

This better accuracy means you can trust your quality data more, leading to more reliable insights.

2. See Everything Live and Get Quick Information

Imagine knowing the exact quality status of every batch of products, every production line, or every incoming material right now. Automated QC logs make this possible. Data is collected and ready to see immediately, giving you:

- Live Dashboards: See important quality numbers, defect rates, and how well your processes are doing on easy-to-understand screens.

- Automatic Warnings: Get instant messages for readings that are off, major mistakes, or machine problems.

- Faster Decisions: With the latest information, managers can make smart choices quickly, stopping problems before they get big.

This live view changes quality control from just looking back at what happened to a dynamic, forward-thinking way of managing.

3. Simpler Work and Less Paperwork

The amount of paperwork with manual QC logs can be huge. Automation significantly reduces this burden:

- Go Paperless: No more printing, filing, or storing physical documents.

- Reports Made Automatically: Create reports for rules, trends, and performance summaries with just a click. This saves countless hours.

- Easier Audits: Quickly find old data and show you’re following rules during audits, which means less stress and time.

- Focus on Important Tasks: Quality staff can spend less time on simple data entry and more time on vital tasks like making processes better, analyzing defects, and planning smart quality goals.

4. Better Tracking and Responsibility

In complex manufacturing, being able to track everything is a must. Automated systems create a clear, unchangeable record:

- Digital Timestamps: Every data entry has a date and time stamp, often showing who made the entry, making it clear who is responsible.

- Batch and Lot Tracking: Easily connect quality data to specific product batches. This allows for quick recalls if needed and precise identification of affected items.

- Supplier Quality Management: Bring supplier quality data into your system for complete tracking from raw materials to finished products.

This improved tracking not only helps with rules but also builds customer trust and helps solve problems quickly.

5. Deeper Analysis for Constant Improvement

Perhaps one of the biggest advantages of automated QC logs is how they help you uncover deep insights that you couldn’t get before. With organized digital data, manufacturers can use:

- Trend Analysis: Find patterns that keep showing up in defects, letting you make changes to processes or machines ahead of time.

- Statistical Process Control (SPC): Watch how much your processes change and spot shifts before they lead to bad products.

- Predictive Quality: Use past data to guess potential quality problems, which helps you plan maintenance or adjust processes to prevent them.

- Tools for Root Cause Analysis: Connect with tools like fishbone diagrams and Pareto charts to systematically find and fix the real reasons for problems.

This data-driven approach encourages a culture of continuous improvement, where information leads to clear improvements in product quality and how well operations run.

Technologies Making Automation Possible

The shift to automated QC logs is happening thanks to many advanced technologies working together to create strong, smart systems.

Quality Management Software (QMS):

At its core, specialized QMS platforms provide a central place for all quality-related activities. These systems are designed to manage documents, control non-conforming products, handle corrective and preventive actions (CAPA), manage audits, and, of course, track all QC data. Modern QMS solutions are often cloud-based, meaning they can be accessed from anywhere and easily updated.

Industrial Internet of Things (IIoT):

IIoT sensors and devices are crucial. These tiny, smart tools can be placed directly on machinery, production lines, or in testing areas to automatically collect data like temperature, pressure, vibration, weight, and dimensions. This data flows directly into the QC log system without human involvement.

Data Analytics and Business Intelligence (BI) Tools:

Once data is collected, BI tools and advanced analytics platforms turn raw numbers into useful insights. They create dashboards, generate reports, identify trends, and can even use machine learning to predict potential issues.

Cloud Computing:

Cloud platforms offer the power and flexibility needed to store vast amounts of data, run complex analyses, and provide access to QC systems from anywhere, ensuring data security and scalability.

Mobile Devices:

Handheld tablets and smartphones are becoming essential tools for quality inspectors on the factory floor. They can use these devices to input data, capture photos of defects, access standard operating procedures (SOPs), and receive alerts in real-time.

Integration Capabilities:

The ability of automated QC systems to integrate with other enterprise systems (like ERP – Enterprise Resource Planning, MES – Manufacturing Execution Systems, or LIMS – Laboratory Information Management Systems) is key. This creates a unified data ecosystem, ensuring seamless information flow across the entire operation.

Steps to a Successful Automation Journey

Implementing automated QC logs isn’t an overnight change; it’s a strategic journey that requires careful planning and execution. Here are key steps to consider:

1. Assess Your Current State:

Start by fully understanding your existing manual QC processes. Identify pain points, bottlenecks, and areas where errors frequently occur.

2. Define Your Goals:

What do you hope to achieve with automation? Is it improved accuracy, faster reporting, better compliance, or deeper insights? Clear goals will guide your system selection and implementation.

3. Choose the Right Technology Partner:

Research and select a QMS or dedicated QC logging solution that fits your industry, scale, and specific needs. Look for user-friendly interfaces, strong integration capabilities, and reliable support.

4. Phased Implementation:

Don’t try to automate everything at once. Start with a pilot project in one area or for a specific product line. Learn from this phase before expanding.

5. Data Migration and Integration:

Plan carefully how you’ll transfer existing data (if necessary) and how the new QC system will connect with your other software.

6. Training and Change Management:

This is crucial. Your team needs proper training on the new system. Address their concerns and communicate the benefits of automation to get their buy-in.

7. Monitor and Optimize:

After implementation, continuously monitor the system’s performance. Use the data it provides to fine-tune your processes and get the most out of your investment.

The Future of Quality is Automated

The manufacturing sector is changing rapidly, and quality control must evolve with it. Automating QC logs is no longer a luxury; it’s a necessity for manufacturers who want to stay competitive, compliant, and consistently deliver high-quality products.

By embracing these digital tools, factories can move beyond reactive problem-solving to proactive prevention. They can transform mountains of paper into valuable insights, empowering their teams to make smarter decisions and drive continuous improvement. The future of manufacturing is precise, efficient, and, without a doubt, automated. Are you ready to make the switch and unlock the full potential of your quality operations?