Key Takeaways

- Most BoL errors come from fragmented data handoffs, not careless staff.

- Documentation automation reduces rework loops more than it improves “accuracy.”

- Cycle time losses hide between approvals, corrections, and late-stage edits.

- Rigid validation rules prevent downstream delays better than human review.

- Automation works best where processes are standardized before volumes spike.

- Anyone who has worked at a shipping desk understands the uncomfortable reality: most delays do not stem from trucks breaking down or ports experiencing congestion. They come from paperwork. Alternatively, the delays often result from incomplete or inaccurate paperwork.

- The Bill of Lading (BoL) sits at the center of that problem. It is simultaneously a contract, a receipt, a compliance artifact, and—depending on the mode—sometimes a financial document. That’s already too many jobs for one form. Then layer on commercial invoices, packing lists, certificates of origin, export declarations, and carrier-specific variants. Suddenly, a shipment is less about moving goods and more about moving documents without mistakes.

- Automation enters this space not as a flashy AI story, but as a corrective measure. Automation serves to mitigate human-induced errors and streamline cycle times, which have gradually increased over time. And yes, it works—but only if you understand why errors happen in the first place and where cycle time actually leaks.

Also read: Purchase Order Automation in Complex Manufacturing Environments

Why BoL Errors Are So Persistent

There’s a misconception that BoL errors exist because organizations are still “manual”. In reality, most enterprises are already partially digitized. The problem is fragmentation, not paper.

A typical scenario looks like this:

- Shipment details originate in ERP or WMS

- Carrier booking happens in a TMS or portal

- Commercial terms come from sales or procurement systems

- Regulatory data is pulled from master data tables that are… questionable

- Final documents are assembled manually in spreadsheets or PDFs

Every handoff introduces interpretation. Every interpretation introduces drift.

Common errors are rarely dramatic. They’re subtle:

- Weight discrepancies between packing list and BoL

- Mismatched HS codes between invoice and customs declaration

- Old consignee addresses reused “just this once”

- Incoterms copied from a previous shipment because they’re “usually the same”

None of these feel catastrophic when created. They become catastrophic three days later, when a container is stuck because customs systems reject the filing.What automation does well here is not intelligence—it’s consistency. It enforces the same logic, the same validation rules, and the same data lineage every single time. Humans, even good ones, don’t.

Error Reduction: Less About Accuracy, More About Eliminating Rework

Most teams frame automation benefits as “improving accuracy”. That’s technically true, but it misses the operational pain point.

The real cost of BoL errors isn’t that the document is wrong. It’s that fixing it requires:

- Back-and-forth emails with carriers

- Document reissuance and version confusion

- Amended filings with customs authorities

- Manual escalation because the shipment is already in transit

In one manufacturing client (automotive Tier-1), over 18% of export shipments required at least one document correction post-submission. This was not due to carelessness on the part of the staff but rather to the fact that data was dispersed across multiple locations and there was a lack of trust in a single source to ensure its integrity.

Once document automation was introduced—with system-driven data extraction, rule-based validation, and automated BoL generation—the correction rate dropped below 3%. The intriguing part? Staff headcount didn’t change. What changed was how often they had to redo work they already thought was finished.

Automation reduced:

- Duplicate data entry across documents

- Free-text fields where structured data should exist

- Late-stage manual edits that bypassed validation

That’s where error reduction actually pays off—by shrinking the rework loop.

Cycle Time: Where the Days Really Disappear

Ask most shipping teams how long it takes to generate a BoL, and you’ll hear “a few minutes”. That answer is technically correct and operationally meaningless.

The real cycle time starts earlier and ends later:

- Shipment readiness confirmed

- Data gathered from multiple systems

- Documents prepared and reviewed

- Carrier submission

- Corrections requested

- Revised documents issued

- Final approval and release

When automation is absent, steps 2 through 6 stretch unpredictably. Not because the tasks are hard—but because they’re interrupt-driven.

A coordinator prepares documents, gets pulled into something else, waits for missing data, resumes later, then discovers something changed upstream. Multiply that by hundreds of shipments per week.

Automated documentation changes the rhythm entirely:

- Data is pulled automatically at shipment readiness

- Validation runs immediately, not after submission

- Exceptions are flagged early, when fixes are cheap

- Documents are generated once, not revised repeatedly

In practice, teams see:

- Same-day document readiness instead of next-day

- Carrier cut-off times met consistently

- Fewer “urgent” escalations late in the evening

Cycle time gains are usually small on a single shipment. They compound across volume. That’s the difference.

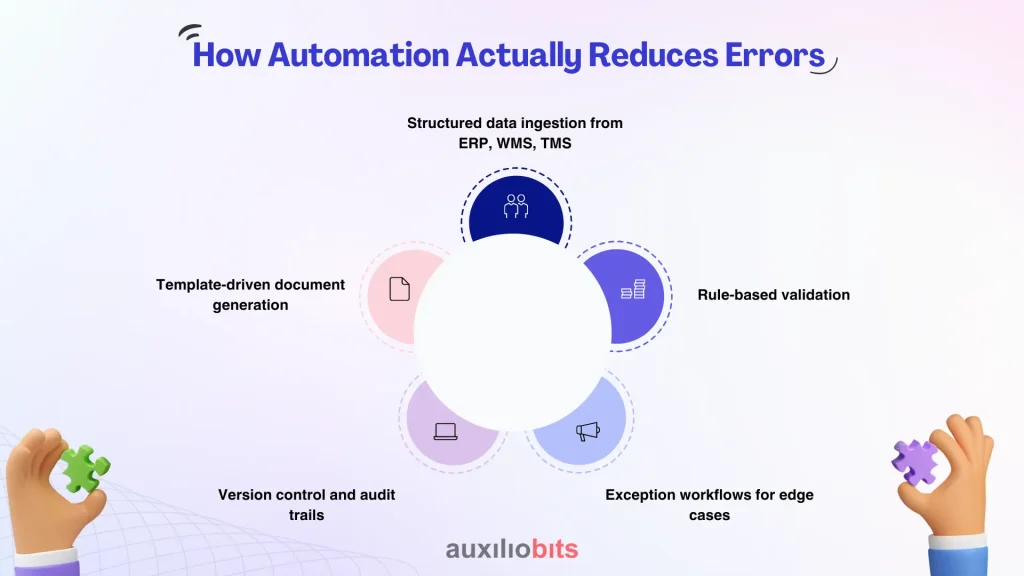

How Automation Actually Reduces Errors

There’s a temptation to overcomplicate this space with heavy AI narratives. In reality, most BoL automation success comes from a few pragmatic capabilities:

- Structured data ingestion from ERP, WMS, TMS

- Rule-based validation (weights, dimensions, mandatory fields)

- Template-driven document generation

- Version control and audit trails

- Exception workflows for edge cases

Notice what’s missing: prediction, optimization, “learning” systems. Those have a place later. First, you remove the variability that shouldn’t exist.

One logistics service provider automated ocean export documentation by enforcing simple rules:

- Gross weight must equal sum of package weights

- HS codes must exist in the master table, no free text

- The consignee name must match booking record exactly

The system rejected documents early. Annoying at first. Then liberating. Error rates dropped, and so did customer complaints about last-minute delays.

Sometimes rigidity is the feature.

When Automation Fails

It’s worth saying this out loud: automating bad data doesn’t fix anything. It just accelerates failure.

Common failure modes include:

- Master data that hasn’t been maintained in years

- Carrier-specific requirements not captured formally

- Local compliance nuances ignored in global templates

In one case, an exporter automated BoL generation across regions without accounting for country-specific legal language. Documents were “perfect” from a system standpoint—and rejected by local authorities.

The lesson isn’t to avoid automation. It’s to scope it honestly.

Start with lanes, products, or geographies where rules are stable. Expand gradually. Automation is less forgiving than humans, and that’s a double-edged sword.

The Hidden Benefit: Cognitive Load Reduction

This part rarely shows up in business cases, but practitioners feel it immediately.

When documentation is automated, shipping teams stop holding fragile context in their heads:

- “Did we change the consignee name on this one?”

- “Which version did we send to the carrier?”

- “Is this the updated invoice or the old one?”

That mental overhead is exhausting—and it leads to mistakes precisely when people are tired or rushed.

Automated workflows externalize that memory:

- The system knows which version is final

- The system knows what changed and when

- The system enforces sequence

People stop acting as buffers. They focus on exceptions, not repetition.

Real-World Impact: A Compressed Export Timeline

A mid-size chemicals manufacturer exporting from Asia to Europe struggled with chronic document delays. Small mismatches, not massive errors, triggered customs queries.

Before automation:

- Average document cycle time: ~36 hours

- Error-related rework rate: ~22%

- Frequent shipment rollovers due to missed cut-offs

After automating BoL and supporting documents:

- Document cycle time: under 6 hours

- Rework rate: under 5%

- Near-zero rollovers caused by documentation

The team didn’t become faster. The process became less fragile.

Why This Matters More as Volumes Grow

Manual documentation processes scale linearly with volume. Errors scale faster.

As shipment counts increase:

- More variations appear

- More edge cases surface

- There is an increased focus on reducing costs.

Automation doesn’t just handle volume. It absorbs variability.

That’s why organizations feel the benefit most during peak seasons. When humans are stretched thin, systems don’t get tired.

A Final Thought

Automating Bill of Lading and shipping documentation isn’t glamorous. It won’t impress anyone at a demo day. But it quietly fixes two of the most persistent operational problems in logistics: avoidable errors and invisible cycle time loss.

The real question isn’t whether to automate. It’s whether you’re willing to standardize enough to let automation work.

And that’s usually the harder decision.