Key Takeaways

- Traditional visibility tools are reactive—they struggle with delays, silos, and static forecasting, leaving organizations blind to real-time disruptions.

- Agents bring proactive intelligence by continuously monitoring shipments, predicting demand shifts, and suggesting or executing adjustments.

- Real-world deployment requires foundations—clean data, reliable integrations, governance frameworks, and operator trust are essential for success.

- Human oversight remains critical—agents can automate routine actions but must not replace judgment-heavy trade-offs in customer service or strategic planning.

- The future lies in collaboration—multi-agent ecosystems will push supply chains toward self-healing networks where disruptions are anticipated, mitigated, and often resolved before they escalate.

Supply chains are inherently chaotic. You can plan every shipment down to the hour, but life has a way of ignoring plans. I once watched an entire week of production schedules get thrown off because a single container was stuck at customs. Nothing in the ERP predicted it, nothing on the dashboard even hinted at trouble. That’s the reality most of us live with.

Agent-driven systems are not flawless solutions, but they represent a step closer to reality than traditional visibility platforms. These software “agents” monitor constantly, learn from historical and real-time patterns, and sometimes act. They can alert managers about potential delays, recommend reroutes, or even adjust schedules autonomously. While they do make errors—such as overprioritizing non-critical shipments or flagging false positives—their ability to prevent cascading disruptions often outweighs their imperfections.

Also read: Coordinating Supply Chain Teams Using CrewAI Architecture

The Weak Spots in Traditional Visibility

Traditional visibility frameworks are designed around structured reporting cycles, static integrations, and historical data models. This creates blind spots in today’s dynamic global logistics environment.

- Slow reporting cycles: Many dashboards rely on daily or weekly updates. A snapshot showing yesterday’s shipment status is of little use if a truck is delayed right now.

- System silos: ERP, TMS, and WMS platforms often operate independently. A customs clearance issue may appear in one system but remain invisible to planners relying on another.

- Historical forecasting limitations: Traditional forecasting models use past trends to predict future demand. However, they fail to account for sudden shifts, such as spikes driven by viral social events or unanticipated supply chain shocks.

- Reactive posture: Teams often discover issues only after they have escalated into major problems, forcing costly emergency responses.

In this environment, companies are left reacting rather than anticipating. Agent-driven systems break this cycle by offering proactive detection, dynamic response options, and continuous feedback loops.

How Agents Work in Practice

The word “agent” often evokes science-fiction images of fully autonomous machines. In reality, supply chain agents are digital entities programmed to monitor, reason, and sometimes act—while humans remain firmly in control.

1. Tracking in real time: Consider a global electronics manufacturer. By connecting agents to GPS trackers, traffic feeds, and carrier APIs, they were able to flag a container delay hours before human operators noticed. This early warning did not eliminate the delay but gave planners enough time to adjust downstream production schedules and reassign labor.

2. Forecasting changes: Agents excel at detecting anomalies in demand and supply. They can notice an impending raw material shortage, detect an unusual demand surge from social sentiment analysis, or simulate the impact of a late shipment. The caveat: agents can overcompensate. An unnecessary stock movement might be triggered by a minor delay. Human oversight ensures that the right decisions are made.

3. Automated adjustments: In some deployments, agents are empowered to act. They may reroute shipments, suggest internal stock transfers, or reprioritize distribution. However, automation requires guardrails. There are instances where agents, driven by efficiency logic, might choose the cheapest carrier for a VIP client, ignoring relationship or service quality considerations. Humans must remain the arbiters of judgment-heavy trade-offs.

Making Sense of Real-Time Data

Data is only useful when it’s meaningful. Agents excel at combining streams from multiple sources:

- IoT sensors report temperature, vibration, or GPS location.

- External feeds include carrier APIs, customs updates, and weather alerts.

- Internal ERP or WMS logs provide the baseline.

The challenge is relevance. Minor GPS deviations in urban deliveries aren’t important. A customs delay, however, can derail weeks of production. Agents help filter noise—but they’re not perfect. Some alerts are false positives, and humans still need to sort out which require action.

Forecasting That Adapts

One thing in practice: forecasting always surprises you. Agents don’t remove that uncertainty—they just respond faster. They can:

- Pick up early signs of demand surges from social trends, events, or competitor actions.

- Model the ripple effect of a supplier outage across production and logistics.

- Simulate alternative routes, carriers, and stock allocation plans in seconds.

Even so, agents make mistakes. They might overreact to minor delays or misread a data anomaly. But the difference is speed—errors are corrected faster than humans could respond manually.

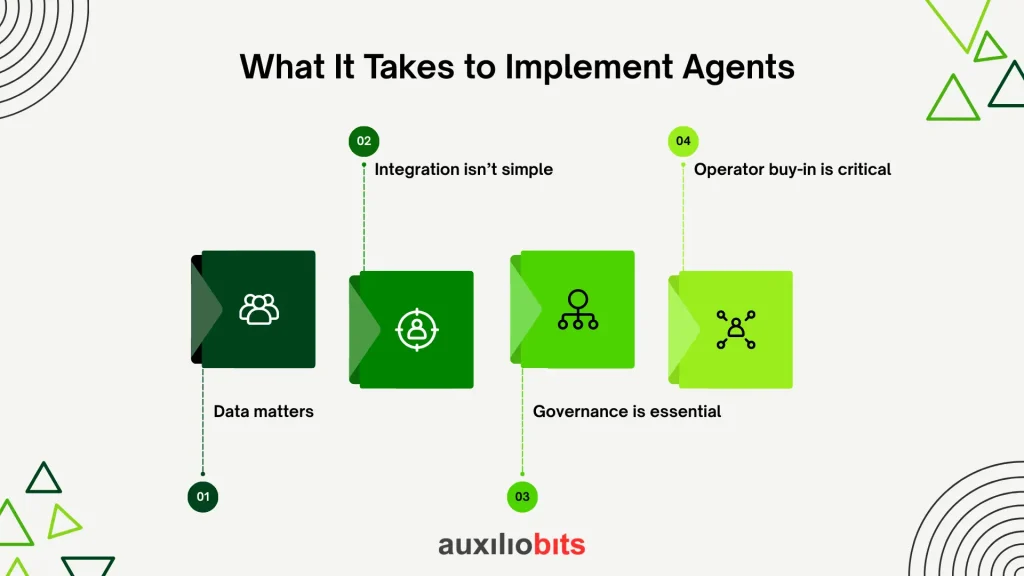

What It Takes to Implement Agents

Deploying agent-driven systems is often more work than companies expect. A few practical realities:

- Data matters. Inconsistent or missing sensor feeds make agents useless.

- Integration isn’t simple. Connecting agents to legacy ERPs, WMS, and TMS systems takes time and planning.

- Governance is essential. Decide which decisions agents can make and which require human approval.

- Operator buy-in is critical. People fear automation replacing them, but most discover that agents reduce stress and repetitive work.

Recommendations

For organizations evaluating agent-driven systems, several pragmatic steps improve adoption outcomes:

- Start small: Target a critical shipment flow or single trade lane rather than attempting enterprise-wide deployment from day one.

- Measure impact: Track KPIs such as forecast accuracy, shipment delays, and cycle times to quantify improvements.

- Demand transparency: Black-box decisioning erodes trust. Agents should explain why specific actions are suggested.

- Iterate continuously: As more data is integrated and feedback loops expand, agents improve in accuracy and reliability.

- Keep humans in charge: Strategic and judgment-based decisions must remain with managers, not algorithms.

The Future of Agent-Driven Visibility

Agent-driven supply chain systems are evolving beyond monitoring and adjustment into broader orchestration roles. With the maturation of multi-agent systems, different agents may soon collaborate across procurement, logistics, and production functions. Imagine a procurement agent negotiating with a supplier agent, while a logistics agent simultaneously reroutes shipments based on agreed timelines.

This ecosystem approach shifts supply chains from reactive firefighting toward self-healing networks—where disruptions are anticipated, adjustments are automatic, and human managers focus on strategy rather than execution.

Conclusion

Supply chains thrive or falter on visibility. Traditional systems, while reliable for structured reporting, fail to capture the unpredictability of real-world disruptions. Agent-driven visibility bridges this gap by continuously monitoring, learning, and adjusting in real time.

These agents are not magic, nor are they error-free. They require clean data, thoughtful governance, and human oversight. Yet their value lies in speed—turning delays into manageable adjustments rather than crises. Organizations that embrace them move closer to proactive, resilient supply chains capable of adapting to shocks instead of being derailed by them.

As global networks grow more complex, the question is no longer whether agent-driven visibility has merit. The real challenge is how quickly enterprises can integrate these systems, refine them through experience, and strike the right balance between autonomy and human judgment. Those that succeed will not just react faster to disruptions—they will anticipate them and, increasingly, stay two steps ahead.