Key Takeaways

- Dashboards provide visibility but rarely enable immediate action.

- Action-oriented agents detect issues and trigger timely interventions.

- Humans remain essential for nuanced, high-stakes supply chain decisions.

- Real-time data, decision rules, and scenario simulation make supply chains proactive.

- Collaborative agent systems improve efficiency, reduce disruptions, and optimize operations.

For a long time, supply chain executives have relied on dashboards to manage their operations. The idea is simple: a centralized view of inventory levels, shipment statuses, supplier performance metrics, and demand forecasts should, in theory, provide enough visibility to make informed decisions. And yet, time and again, these dashboards fail to prevent costly disruptions. Why? This is because visibility alone, especially when it is passive, retrospective, or static, does not translate into action.

Let’s be clear: dashboards are useful. They aggregate data, highlight trends, and help organizations spot anomalies. But consider a scenario many companies are all too familiar with: a key supplier in Southeast Asia experiences a labor strike. Your dashboard shows “delayed shipment” two days later. By the time you notice, the shipment has already been rerouted or canceled, and downstream operations are scrambling. Visibility lagged behind reality.

The problem isn’t just the lag—it’s the lack of action. Dashboards tell you what happened. They rarely tell you what to do. In complex, hyperconnected supply chains, this distinction matters more than ever.

Also read: How are Multi-Agent AI Systems Redefining Supply Chain Optimization?

The Limits of Traditional Dashboards

Most supply chain dashboards share a common set of features:

- Static KPIs: Metrics like on-time delivery, inventory turnover, or lead times are measured but not contextualized in real time.

- Historical snapshots: Many dashboards rely on yesterday’s data, making them inherently reactive.

- Siloed data streams: Operations, procurement, logistics, and finance often feed into separate dashboards, creating fragmented insights.

These features can lull organizations into a false sense of security. A procurement manager might see that vendor A has 95% on-time performance and assume the supply chain is healthy, without noticing that a shipment en route has already been delayed by three days. Meanwhile, operations is scrambling, and finance is recalculating working capital. The dashboard’s “visibility” didn’t prevent friction—it merely documented it.

Even advanced analytics or predictive dashboards have limitations. Forecasting demand spikes, transportation delays, or supplier failures requires accurate, high-frequency data. Many organizations still rely on batch data updates or manually reconciled ERP reports. As a result, predictions are often outdated the moment they’re generated.

Why Action-Oriented Agents Are Critical

Enter action-oriented agents: autonomous or semi-autonomous systems that do more than observe—they act. These agents are not merely data collectors or visualization tools; they’re decision facilitators. Think of them as a mix between a supply chain analyst and a project manager who never sleeps.

Some real-world illustrations:

- Automated rerouting: A logistics agent can detect a port congestion alert from external maritime data sources, simulate alternative routes, and automatically trigger transport changes—all without waiting for a human to spot the issue.

- Supplier engagement: An agent monitoring supplier health scores can preemptively contact vendors or initiate backup sourcing protocols when risk thresholds are crossed.

- Inventory optimization: Agents can identify slow-moving stock and dynamically suggest redistribution or promotional strategies to prevent overstocking or stockouts.

These interventions reduce reaction time from hours or days to minutes, which is the difference between a minor hiccup and a multi-million-dollar disruption.

The Human Factor Still Matters

Before you imagine a warehouse full of bots making autonomous decisions, a note of caution: agents aren’t magic. They excel when integrated with human expertise. Humans still set policies, validate edge-case decisions, and interpret qualitative context that machines struggle with.

Consider this example: a machine learning agent flags a supplier as high-risk due to a sudden drop in delivery reliability. On its own, it might suggest cutting orders immediately. But a procurement manager knows that the supplier’s delay is due to temporary customs delays, and that relationships and contract penalties favor maintaining engagement. Agents without human context can create unnecessary friction.

The takeaway: action-oriented agents should augment decision-making, not replace it. They provide speed, consistency, and scale, while humans provide judgment, nuance, and strategic oversight.

Moving from Passive Visibility to Active Supply Chain Control

Transitioning from dashboards to agents requires a mindset shift. Organizations must stop asking “What’s happening?” and start asking “What should happen next?”

1. Integrate Real-Time Data Feeds

Static dashboards often fail because they rely on delayed ERP or TMS data. Agents require streaming data from multiple sources:

- IoT sensors on warehouse shelves and transport vehicles

- Supplier and partner APIs for shipment tracking

- External risk feeds (weather, port strikes, geopolitical alerts)

- Market intelligence and demand signals

The richer and faster the data, the more precise the agent’s interventions can be.

2. Establish Actionable Decision Rules

Not every alert warrants intervention. A good agent requires clearly defined thresholds and decision pathways. Examples:

- Trigger secondary supplier orders if lead time variance exceeds 15%

- Automatically reallocate inventory if regional demand exceeds forecast by 10%

- Alert human managers only for high-impact anomalies (e.g., multi-day port delays)

This prevents “alert fatigue,” a common problem with passive dashboards, where too many warnings are ignored or misprioritized.

3. Enable Scenario Simulation

Agents don’t just react—they can simulate multiple courses of action before executing. For example:

- Testing alternative shipping routes and predicting associated costs

- Running supplier substitution scenarios and analyzing impact on production

- Forecasting the impact of demand surges on inventory across multiple warehouses

Simulation capability ensures that interventions are proactive, not just reactive.

4. Foster Human-Agent Collaboration

As noted earlier, humans and agents must collaborate closely. Dashboards traditionally communicate to humans; agents communicate with humans and other agents. Integrating feedback loops—where humans validate, refine, or override agent recommendations—enhances trust and adoption.

Case Example: Automotive Manufacturing

A major automotive OEM faced repeated production halts due to delayed component shipments from Asia. Their dashboard team could report the delays, but action took days, causing costly line stoppages.

By deploying action-oriented agents, the OEM achieved:

- Automated alerts to procurement teams within minutes of supplier delays

- Dynamic rerouting of shipments using multiple carriers and transport modes

- Predictive inventory allocation to buffer production lines against high-risk suppliers

The result? Production line stoppages fell by 40%, supplier engagement improved, and planners finally moved from firefighting to proactive management.

This example underscores a key insight: dashboards provide information; agents provide operational control.

Common Misconceptions About Action-Oriented Agents

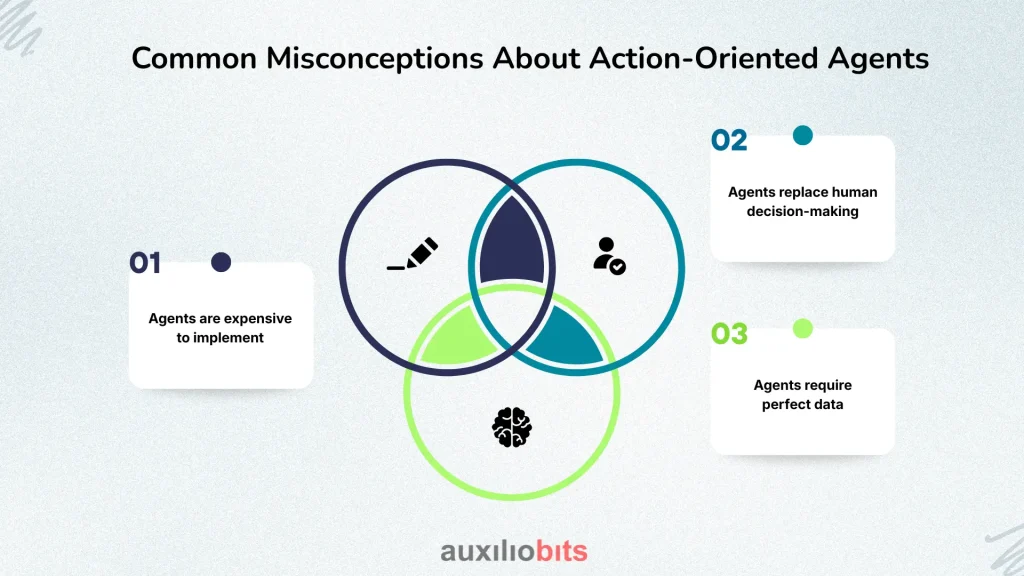

Many organizations hesitate to adopt agents due to misconceptions:

- “Agents are expensive to implement.” Yes, upfront investment is required, but the ROI is realized quickly through reduced disruptions, optimized inventory, and labor savings.

- “Agents replace human decision-making.” They augment human intelligence. Humans remain in the loop for high-stakes, nuanced decisions.

- “Agents require perfect data.” Not true. Agents can function with imperfect data using probabilistic models, confidence scores, and escalation rules.

In practice, incremental deployment—starting with high-impact processes like logistics rerouting or supplier risk management—often yields measurable gains before scaling to the full supply chain

The Role of Agent Collaboration

Visibility alone often fails because decisions are isolated. Even the best dashboard won’t coordinate between procurement, production, and logistics. Agents, by contrast, can interact with each other:

- Procurement agents can request updates from logistics agents before confirming orders

- Demand planning agents can advise inventory agents on seasonal spikes

- Finance agents can evaluate cost implications of alternative sourcing

This collaborative ecosystem ensures decisions are aligned across functions. It’s like having a supply chain orchestra where each agent plays in harmony, rather than a collection of soloists staring at separate dashboards.

Dashboards are seductive. They promise clarity, organization, and control. But clarity without agency is like a car with a perfect speedometer but no accelerator. The metrics are visible, but the journey doesn’t move. Real supply chain resilience comes from systems that act decisively and intelligently—agents that bridge the gap between observation and execution.

Organizations that embrace this shift will not only survive disruptions but anticipate and mitigate them in ways that dashboards alone never could. And in a world where supply chain shocks are increasingly frequent, this is no longer a luxury—it’s essential.