Key Takeaways

- ERP systems record transactions well, but they don’t eliminate human-driven procurement work.

- Most AI in procurement supports decisions; it doesn’t replace accountability or control.

- Manufacturing procurement complexity breaks simplistic “plug-and-play” automation models.

- Real automation starts by removing manual decisions, not adding new dashboards.

- Teams gain strategic value when automation removes coordination noise, not people.

Walk into almost any manufacturing procurement office, and you’ll hear the same frustrations, phrased slightly differently.

“Why are vendor approvals still stuck in email?”

“Why does GRN matching break every month-end?”

“Why does the ERP show the data, but nothing actually moves?”

And almost inevitably, two beliefs surface—sometimes spoken out loud, sometimes quietly assumed:

- “Once we upgrade the ERP, procurement automation will fall into place.”

- “AI sounds powerful, but it’s risky for core procurement processes.”

Both ideas sound reasonable. Both are deeply misleading.

Manufacturing procurement doesn’t fail because leaders lack systems or ambition. It fails because automation is often misunderstood—confused with digitization, or treated as a risky science experiment instead of an operational tool.

Let’s dismantle these myths, one uncomfortable reality at a time.

Also read: How Agentic Automation Detects Procurement Anomalies Before Posting

Myth 1: “Our ERP Will Solve Procurement Automation”

This belief has survived multiple ERP generations. SAP. Oracle. Microsoft. Infor. The names change; the expectation doesn’t.

The thinking goes something like this: “Once the ERP is fully implemented, standardized, and configured, procurement will run smoothly.”

Except… it rarely does.

ERPs Are Record Systems, Not Work Systems

Here’s the part that doesn’t get said often enough in boardrooms:

ERPs are excellent at storing, validating, and reporting data. They are terrible at handling human-driven workflow chaos.

Procurement in manufacturing is messy by nature:

- Suppliers send invoices in different formats

- Buyers negotiate exceptions over WhatsApp and email

- Plants raise urgent POs outside normal cycles

- Approvals depend on availability, not policy charts

An ERP expects structured inputs at structured points. Procurement reality doesn’t comply.

So what happens?

People adapt.

They build shadow processes around the ERP:

- Excel trackers for pending approvals

- Email chains that never touch the system

- Manual re-entry of vendor data already “digitized” somewhere else

The ERP becomes the final destination, not the process engine.

A Familiar Example: Vendor Onboarding

Ask a manufacturing firm how vendor onboarding works, and you’ll hear something like this:

- Vendor emails documents

- Procurement validates manually

- Compliance checks run outside the ERP

- Finance reviews bank details over email

- Someone finally creates the vendor master in ERP

Technically, the ERP “supports” vendor creation. Operationally, humans carry the process end to end.

No amount of ERP customization fixes this, because:

- Document interpretation happens before data entry

- Cross-functional coordination happens outside system boundaries

- Exceptions outnumber standard cases

ERP upgrades don’t remove these steps. They just give them a newer screen.

Why ERP-Centric Automation Hits a Ceiling

Manufacturing leaders eventually notice patterns:

- Automation stalls at 30–40%

- Cycle times barely improve despite better dashboards

- Headcount doesn’t reduce—just shifts tasks

That’s because ERP automation focuses on:

- Rules

- Transactions

- Predefined workflows

Procurement reality depends on:

- Context

- Judgment

- Follow-ups

- Reminders

- Interpretation

These aren’t ERP-native strengths.

What Works Instead

Effective procurement automation in manufacturing usually sits around the ERP, not inside it.

Think:

- Automation that reads incoming vendor emails

- Systems that validate documents before ERP entry

- Bots that chase approvals instead of waiting

- Logic that handles “almost correct” data

The ERP remains the system of record—but it’s no longer expected to run the show.

That distinction alone changes outcomes dramatically.

Myth 2: “AI Is Too Risky for Procurement”

This concern is understandable—and often justified, depending on what people mean by “AI.”

Many leaders hear AI and imagine:

- Black-box decisions

- Autonomous systems changing vendor terms

- Compliance exposure

- Auditors asking uncomfortable questions

No procurement head wants to explain to finance why a model “decided” something.

But here’s the nuance that often gets lost: Most procurement AI does not make decisions.

It makes recommendations, classifications, and predictions.

Humans still approve. Systems still log actions.

Where the Fear Comes From

Manufacturing procurement has been burned before:

- OCR tools misreading invoices

- Early chatbots giving wrong responses

- Over-promised analytics that never delivered value

So skepticism is healthy.

But dismissing AI entirely because of early failures is like rejecting CNC machines because the first one needed calibration.

Where AI Fits

AI works exceptionally well in procurement when tasks involve:

- Pattern recognition

- Volume

- Repetition

- Probabilistic judgment

Examples that quietly succeed in manufacturing environments:

- Classifying spend categories from unstructured invoices

- Detecting duplicate or near-duplicate vendor submissions

- Flagging abnormal price deviations

- Predicting approval delays based on historical behavior

AI struggles when:

- Policies are undocumented

- Exceptions are political, not operational

- Data quality is completely unmanaged

This is where leadership judgment matters—not blind adoption, not blanket rejection.

Risk Isn’t About AI. It’s About Design.

Most AI risk stories come down to poor implementation choices:

- No human-in-the-loop

- No confidence thresholds

- No audit trails

- No fallback logic

That’s not AI being risky. That’s governance being absent.

In mature procurement environments:

- AI suggests

- Automation executes

- Humans approve or intervene

- Systems log every action

Auditors love that model, by the way. It’s cleaner than manual chaos.

The Hidden Myth: “Automation Means Replacing People”

This belief isn’t always spoken, but it shapes decisions silently.

Procurement teams worry:

- Will automation reduce my team?

- Will expertise be devalued?

- Will local knowledge be ignored?

In manufacturing, procurement isn’t just buying. It’s firefighting.

And automation doesn’t remove that reality—it removes the noise around it.

What Changes on the Ground

When automation is done right:

- Buyers stop chasing approvals

- Analysts stop reconciling mismatched data

- Managers stop asking for status updates

What remains:

- Negotiation

- Supplier development

- Risk management

- Strategic sourcing

Ironically, teams often become more valuable post-automation—not less—because their work becomes visible and defensible.

Real-World Pattern: Why Manufacturing Is Harder Than Other Industries

Procurement automation succeeds faster in services or retail. Manufacturing lags. There are reasons:

- Multi-plant complexity

- Legacy supplier ecosystems

- Mixed compliance regimes

- Tight coupling with production schedules

Automation solutions built for “clean” environments break here.

That’s why simplistic narratives—“just add AI” or “just upgrade ERP”—fail so consistently.

Manufacturing requires:

- Layered automation

- Gradual rollout

- Respect for operational reality

What Manufacturing Leaders Should Reframe Instead

If there’s one mindset shift that consistently works, it’s this:

Stop asking which system will automate procurement. Start asking which manual decisions should stop existing.

That question changes everything.

Suddenly, the focus moves to:

- Why approvals depend on email

- Why documents aren’t validated upstream

- Why exceptions aren’t categorized

- Why follow-ups depend on memory

And automation finally has something real to fix.

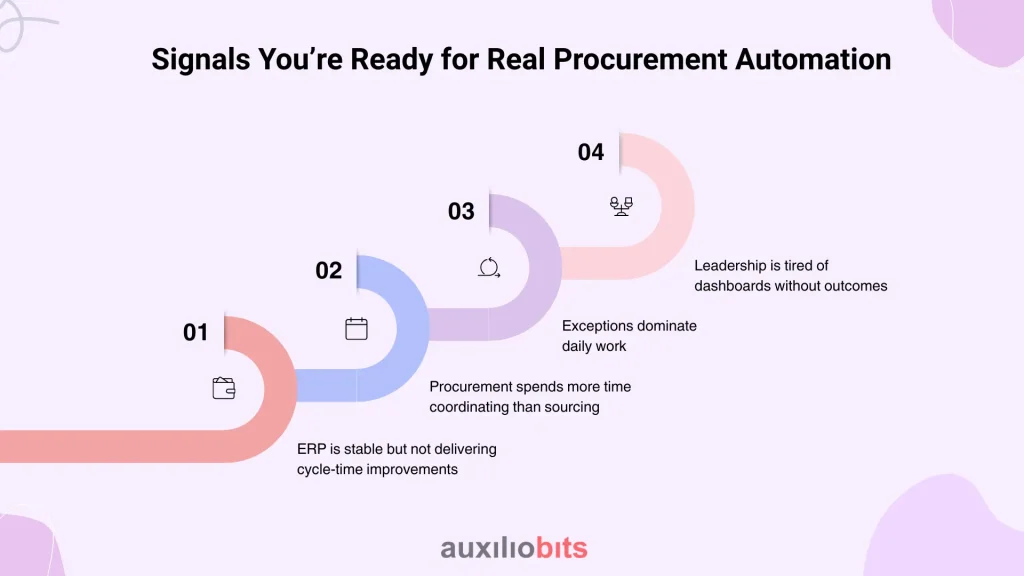

Signals You’re Ready for Real Procurement Automation

Not every organization is ready.

You’re probably ready if:

- ERP is stable but not delivering cycle-time improvements

- Procurement spends more time coordinating than sourcing

- Exceptions dominate daily work

- Leadership is tired of dashboards without outcomes

You’re probably not ready if:

- Processes are undocumented

- Policies change weekly

- Ownership is unclear

- Automation is treated as an IT-only initiative

A Closing Thought

Manufacturing leaders don’t need more technology promises. They need fewer myths.

ERPs won’t magically automate procurement. AI isn’t inherently dangerous.

And automation doesn’t erase human judgment—it exposes where it actually matters.

Procurement automation works when it respects the messiness of manufacturing instead of pretending it doesn’t exist.

That’s the part most vendors won’t tell you.

But it’s the part experienced leaders eventually figure out—usually the hard way.