Key Takeaways

- Most trade compliance failures are documentation failures, not regulatory misunderstandings. Teams generally know the rules. What breaks down is keeping invoices, declarations, classifications, and origin data aligned with how products are actually built, sourced, and shipped—across plants and countries.

- Generating documents faster doesn’t reduce risk if the underlying truth isn’t validated. ERP-driven PDFs create speed, not assurance. Without context-aware validation and cross-checks, automation simply propagates errors at scale.

- Multi-country compliance requires adaptive logic, not global standardization fantasies. HS codes, origin rules, export controls, and documentation formats may share frameworks, but enforcement and interpretation vary by country. Automation must be destination-aware by design.

- The strongest automation models don’t eliminate humans—they protect human judgment. Effective systems let low-risk shipments flow, surface edge cases with context, and capture decision rationale. This reduces fatigue-driven errors and improves audit readiness.

- When automation exposes data and ownership gaps, that’s a feature—not a failure. Broken master data, weak supplier governance, and unclear accountability existed long before automation. Automation simply reveals them earlier, when they’re cheaper to fix.

Trade compliance rarely fails because teams don’t understand regulations. It fails because documentation doesn’t keep up with reality.

Manufacturers that move goods across borders live inside a web of commercial invoices, packing lists, certificates of origin, HS classifications, export control statements, supplier declarations, country-specific annexures, and customs filings that seem to multiply every year. Most compliance issues don’t start with intent. They start with version mismatches, stale declarations, misaligned data fields, or documents created in good faith that no longer reflect how the product is actually built or shipped.

Ask any global trade manager where their time goes, and the answer is rarely “strategy.” It’s chasing paperwork, reconciling differences between systems, responding to customs queries, and explaining—again—why a document generated in Plant A doesn’t look like the one from Plant B.

Automation can help, but not in the simplistic “digitize the form” sense that vendors like to sell. Import–export automation works only when documentation and multi-country compliance are treated as living processes, not static checklists

Also read: Why Manufacturing Needs Decision Automation, Not Just Process Automation

The Hidden Complexity of Trade Documentation

On paper, trade documentation looks standardized. In practice, it’s anything but.

A commercial invoice might be “standard,” but what Germany expects versus what Brazil accepts versus what a U.S. broker flags as risky are three different interpretations of that standard. Certificates of origin vary not just by trade agreement but by issuing authority. Product descriptions that pass in one jurisdiction trigger red flags in another.

Here are a few important realities that rarely appear in polished presentations:

- The same product travels with different identities. Engineering names, sales descriptions, customs descriptions, and regulatory labels are often inconsistent—and not always wrong. Just different lenses.

- Documents age quickly. A supplier declaration that was valid six months ago may now be inaccurate because a subcomponent source changed quietly.

- Manual reconciliation is still the norm. Teams compare ERP outputs with logistics partner documents, broker submissions, and customs feedback—line by line.

And when something goes wrong, the question isn’t “Who made a mistake?” It’s “Which document version did customs see?”

Multi-Country Compliance Is Not One Problem—It’s Many Overlapping Ones

Manufacturers often talk about “global trade compliance” as if it’s a single discipline. It isn’t. It’s an accumulation of country-specific regimes layered on top of shared but inconsistently enforced frameworks.

Consider just a few overlapping dimensions:

- Tariff classification rules that differ in interpretation even under the same HS code

- Export control regimes (EAR, ITAR, EU Dual-Use, local variants) that apply based on product function, not just category

- Sanctions and denied party screening that change weekly, sometimes daily

- Origin rules that vary by free trade agreement and require deep bill-of-materials visibility

- Documentation formats mandated by customs authorities that don’t align cleanly with ERP schemas

Trying to manage this manually across ten or twenty shipping countries is not just inefficient—it’s fragile

Why Traditional Digitization Falls Short

Many manufacturers believe they’ve “automated” trade compliance because documents are generated from ERP systems. But generating a PDF is not the same as ensuring compliance.

ERP-driven documentation tends to fail in predictable ways:

- Static templates don’t adapt to regulatory changes or destination-specific requirements

- Master data errors propagate instantly across thousands of documents

- Human overrides go untracked, especially when emails and spreadsheets are involved

- Supporting documents live elsewhere, disconnected from the transaction record

The result is speed without assurance. Faster document creation, yes. Fewer compliance issues? Not necessarily.

Automation that only accelerates document output without validating context simply moves the risk upstream.

What Works: Documentation-Centric Automation

Effective import–export automation starts with a different question: How do we ensure every document reflects the same truth, at the moment it’s used?

That requires treating documentation as a process with checkpoints, not a byproduct of shipping.

1. Intelligent Document Intake (Not Just OCR)

Manufacturers receive compliance-critical documents from dozens, sometimes hundreds, of external parties: suppliers, brokers, freight forwarders, chambers of commerce.

Basic OCR extracts text. Intelligent automation does more:

- Identify document type (invoice vs. COO vs. supplier declaration)

- Validate mandatory fields by destination country

- Flag missing or contradictory data (e.g., origin vs. manufacturing location)

- Compare against internal master and transactional data

This is where AI helps—not by “understanding trade law,” but by spotting inconsistencies humans miss under volume pressure.

2. Rule-Aware Document Validation

Rules matter, but only when they’re applied in context.

A product shipped to Mexico under USMCA triggers different documentation checks than the same product shipped to Japan. Automation systems need to know why a rule applies, not just that it exists.

Effective validation includes:

- Country-pair specific document requirements

- Agreement-specific origin rules

- Export control thresholds tied to product attributes

- Destination-specific wording constraints (yes, wording matters)

This is also where automation sometimes fails—rules are encoded too rigidly. Real-world trade compliance is full of exceptions, tolerances, and gray zones. Systems must allow escalation, not silent rejection.

3. Continuous Compliance, Not Pre-Shipment Only

Many compliance programs front-load checks before shipment and relax afterward. That’s risky.

Regulatory regimes change mid-cycle. Sanctions lists update. Preferential treatment rules get revised. Automation must support continuous validation, especially for:

- Long-lead manufacturing shipments

- Blanket supplier declarations

- Ongoing contract manufacturing arrangements

Automating Multi-Country Compliance Without Losing Control

Automation often triggers a fear: What if the system gets it wrong? A fair concern.

The answer isn’t blind trust. It’s layered accountability.

Well-designed automation introduces checkpoints rather than removing humans entirely:

- Low-risk shipments flow through with minimal intervention

- Edge cases are flagged with context, not just error codes

- Audit trails capture why a document passed or failed at a given time

- Human decisions are logged and reused as learning signals

In practice, this reduces—not increases—compliance risk. Humans focus on judgment calls instead of data chasing.

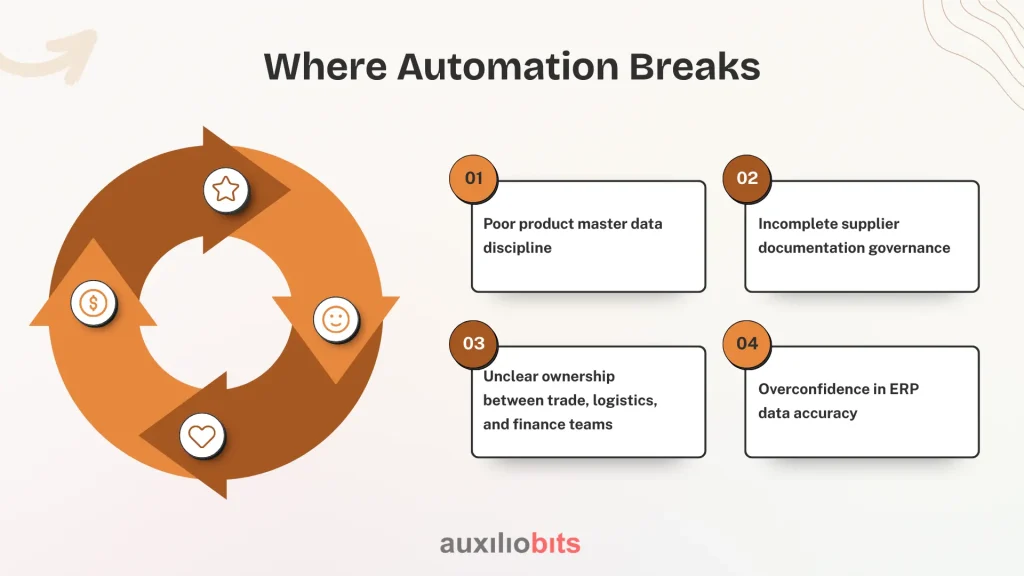

Where Automation Breaks

It’s worth saying out loud: automation fails. And when it does, it reveals weaknesses that were already there.

Common failure points include:

- Poor product master data discipline

- Incomplete supplier documentation governance

- Unclear ownership between trade, logistics, and finance teams

- Overconfidence in ERP data accuracy

These failures aren’t reasons to abandon automation. They’re signals that the organization needs alignment. Automation surfaces problems earlier, when they’re cheaper to fix.

A Real-World Pattern: From Chaos to Control

A mid-size industrial manufacturer shipping to 18 countries struggled with repeated customs holds in Latin America. Each incident looked different, but the root cause was consistent: document mismatches across systems.

They didn’t rip out ERP. They didn’t centralize everything overnight.

Instead, they:

- Automated intake and validation of all inbound trade documents

- Introduced destination-aware document checks

- Created a single compliance “decision layer” above existing systems

- Logged every override with reason codes

Within six months, customs holds dropped sharply. Trade never behaves that neatly, but customs holds dropped sharply enough within six months that logistics teams rarely had to firefight.

The unexpected benefit? Audit prep time fell by more than half. Documentation history was no longer tribal knowledge.

What This Means for Manufacturing Leaders

Trade compliance automation is not about replacing experts. It’s about protecting them from volume, fatigue, and preventable errors.

A few pragmatic takeaways, learned the hard way:

- Standardization helps, but adaptability matters more

- Documentation accuracy beats document speed

- Country-specific nuance is unavoidable—design for it

- Exceptions are not failures; they’re part of the system

- If automation makes people uncomfortable, it’s probably doing something useful

Manufacturers that treat import–export compliance as a documentation problem—not just a regulatory one—tend to scale with fewer surprises. Those that don’t often discover the limits of manual heroics at the worst possible time: when goods are stuck, customers are waiting, and authorities are not in a forgiving mood.

Automation won’t make trade compliance simple. It makes it survivable at scale. And in global manufacturing, that’s often the difference between growth and constant friction.