Key Takeaways

- Most manufacturing organizations don’t struggle because they run multiple ERPs. They struggle because no one owns the logic that reconciles intent across those systems. Automation that ignores reconciliation simply moves the problem downstream—usually to finance.

- The real effort isn’t raising a purchase order—it’s understanding whether that PO still makes sense after demand shifts, supplier constraints, and production changes. Agent-driven models focus on interpretation, not just execution.

- Central teams can design elegant workflows, but plants operate under real constraints—line stoppages, local suppliers, urgent substitutions. Automation that can’t tolerate deviation will be bypassed faster than any policy can enforce it.

- Fewer invoice disputes, fewer escalations, fewer “special approvals” don’t immediately look transformational on a dashboard—but they fundamentally change how procurement, finance, and suppliers interact day to day.

- In sectors where a mismatch only affects reporting, inefficiencies linger. In manufacturing, a mismatched PO can halt production. That pressure forces earlier adoption of systems that can reason, not just route.

Purchase order automation sounds straightforward until you’ve actually lived inside a manufacturing enterprise.

On paper, a PO is just a document: quantity, price, supplier, delivery date, approval. In reality, it’s a coordination artifact across plants, planners, buyers, finance controllers, suppliers, and at least three different systems that all claim to be the “source of truth.” Sometimes four, if acquisitions were involved. Sometimes more, if plants were allowed to “opt out” of central IT decisions fifteen years ago and never quite opted back in.

This is where most conversations about PO automation go wrong. They assume a single ERP, a single workflow, and a clean master data model. That world barely exists outside PowerPoint.

Complex manufacturing environments are fragmented by design. And any serious attempt to automate purchase orders has to start there.

The reality: ERP fragmentation is normal, not an exception

Talk to anyone running procurement across multiple manufacturing plants and they’ll eventually admit it—often quietly—that ERP uniformity is a myth.

You might see:

- SAP ECC in older plants, S/4HANA in newer ones

- Oracle EBS still running MRP for specific product lines

- A local ERP or homegrown system in Asia-Pacific facilities

- A bolt-on procurement tool that never fully replaced email

- Shadow spreadsheets controlling supplier-specific logic

None of this happened because teams were careless. It happened because manufacturing footprints grow through acquisitions, regulatory requirements differ by geography, and production realities don’t wait for global IT roadmaps.

The result is predictable:

- Purchase requisitions originate in different systems

- Approval logic varies by plant, category, or spend threshold

- Supplier pricing is stored inconsistently

- Goods receipt data arrives late—or not at all

- Finance sees the PO only after the invoice shows up

And yet, many automation initiatives still start with: “We’ll standardize the process first.”

That sounds reasonable. It rarely survives contact with reality.

Also read: Manufacturing 2026: What Will Be Automated, What Will Be Agent-Led

Why traditional PO automation stalls in manufacturing

Classic PO automation focuses on workflow digitization: electronic requisitions, approval chains, and automated PO creation inside the ERP. Useful, but incomplete.

In complex environments, three failure patterns repeat.

1. Automation assumes clean inputs that don’t exist

MRP outputs aren’t always trustworthy. Demand signals change mid-cycle. Engineering revisions alter quantities after requisitions are raised. Planners override system suggestions because they know something the system doesn’t.

Automation that blindly converts requisitions into POs ends up accelerating bad decisions, not preventing them.

2. Approval logic doesn’t translate across systems

A central policy might say approvals are based on spend and category. But one plant routes approvals based on production criticality. Another uses supplier risk. A third still relies on a senior buyer’s inbox.

Hard-coding this logic inside each ERP becomes brittle fast.

3. Reconciliation is treated as an afterthought

Most systems assume that once a PO is created, the job is done. In manufacturing, that’s when the real work starts.

- Quantities change

- Delivery dates slip

- Prices get renegotiated mid-order

- Partial receipts occur

- Invoices don’t match, and no one agrees why

This is where finance and procurement spend disproportionate time—reconciling mismatches across systems that were never designed to agree with each other.

The hidden workload: reconciling intent vs. reality

Here’s an uncomfortable truth most automation decks avoid: Purchase order work is less about creation and more about reconciliation.

Reconciling:

- What the planner intended

- What procurement ordered

- What the supplier confirmed

- What the plant received

- What finance is being invoiced

In fragmented ERP landscapes, each of those lives in a different place.

Historically, humans did the stitching:

- Buyers cross-checking emails against ERP screens

- AP teams matching invoices manually

- Plant admins calling suppliers to clarify shortages

- Controllers approving exceptions because “it’s close enough”

This doesn’t scale. It also doesn’t show up clearly in KPIs, which is why it persists longer than it should.

Where agent-driven reconciliation changes the equation

Agent-driven automation approaches PO management differently. Instead of treating the ERP as the single brain, it treats it as one of several information sources.

An agent doesn’t “own” the PO. It understands the PO’s lifecycle.

That distinction matters.

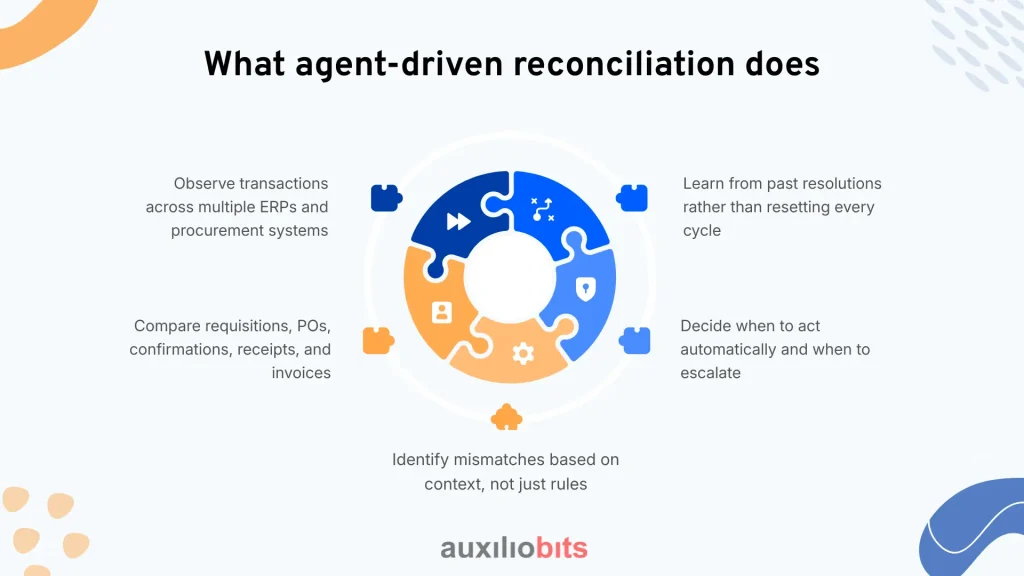

What agent-driven reconciliation does

At a practical level, intelligent agents:

- Observe transactions across multiple ERPs and procurement systems

- Compare requisitions, POs, confirmations, receipts, and invoices

- Identify mismatches based on context, not just rules

- Decide when to act automatically and when to escalate

- Learn from past resolutions rather than resetting every cycle

This isn’t theoretical. It’s already happening quietly in mature manufacturing setups—often starting with invoice matching and expanding upstream.

ERP fragmentation stops being the blocker

One of the more surprising outcomes teams report after introducing agent-driven reconciliation is this: they stop obsessing over ERP unification.

Not because fragmentation disappears—but because it matters less.

Agents don’t care whether a quantity came from SAP or Oracle. They care whether it aligns with:

- Historical ordering patterns

- Supplier-specific tolerances

- Plant consumption behavior

- Contractual pricing bands

- Production schedules

Instead of forcing all systems into a rigid process, agents sit above them, interpreting intent and outcome.

This is particularly valuable in manufacturing environments where:

- Plants operate semi-autonomously

- MRP logic differs by product family

- Supplier relationships vary widely in maturity

- Change is constant, not episodic

A real-world pattern: multi-plant direct materials procurement

Consider a manufacturer with eight plants across three regions.

- Four plants run SAP

- Two run Oracle

- Two still use a regional ERP tied closely to local suppliers

Direct materials are centrally negotiated, but ordering is decentralized.

Before agent-driven reconciliation:

- Central procurement created contracts

- Plants raised POs locally

- Price mismatches were discovered at invoice stage

- AP rejected invoices, suppliers escalated, buyers intervened

- Everyone blamed “the system”

After introducing agents focused on PO reconciliation:

- Agents monitored PO price deviations at creation, not invoicing

- Detected when plants used outdated price lists

- Flagged quantity anomalies relative to recent consumption

- Automatically corrected POs within tolerance

- Routed only genuine exceptions to buyers

The surprising result wasn’t just fewer mismatches. It was fewer arguments.

People stopped fighting symptoms and started trusting the signals.

Where this approach works—and where it doesn’t

Agent-driven reconciliation isn’t a silver bullet. It’s effective precisely because it’s selective.

It works well when:

- Variability is normal, not exceptional

- Data is imperfect but available

- Human judgment is currently compensating for system gaps

- The same issues repeat with slight variations

Manufacturing checks all those boxes.

It struggles when:

- Data access is restricted or siloed for political reasons

- Exception handling rules are constantly changing without feedback loops

- Teams expect zero false positives from day one

- There’s no agreement on what “correct” looks like

Agents amplify clarity. They don’t create it from nothing.

PO automation stops being a workflow problem

One subtle shift happens when organizations adopt this mindset: they stop treating PO automation as a workflow project.

Instead, it becomes a decision automation problem.

Questions agents help answer continuously:

- Is this PO aligned with actual demand, or just historical habit?

- Is the price deviation meaningful, or noise?

- Is this supplier behavior unusual, or seasonal?

- Does this mismatch require human attention—or just acknowledgment?

Humans still decide policy. Agents handle interpretation at scale.

That division of labor feels natural once teams experience it. Before that, it sounds abstract.

The benefits procurement teams notice first

Not everything shows up in dashboards. Some improvements are felt before they’re measured.

Procurement teams often report:

- Less time spent explaining exceptions to finance

- Fewer “urgent” escalations that aren’t actually urgent

- Better conversations with suppliers, grounded in facts

- More confidence delegating routine work to junior staff

Finance notices too, eventually:

- Cleaner three-way matches

- Fewer accrual surprises

- More predictable period closes

None of this requires replacing ERPs. That’s the point.

Why manufacturing is ahead of other sectors here

Ironically, manufacturing—often seen as slow to modernize IT—is ahead of sectors like retail or professional services when it comes to agent-driven PO reconciliation.

Why?

Because complexity forced the issue early.

- Volume is high

- Margins are sensitive

- Errors compound quickly

- Workarounds have real operational costs

When a PO mismatch stops a production line, tolerance for inefficiency evaporates fast.

The takeaway

If your PO automation strategy assumes a clean ERP landscape, it’s already outdated.

Manufacturing doesn’t need prettier workflows. It needs systems that understand messy reality and still make reliable decisions.

Agent-driven reconciliation doesn’t eliminate complexity. It absorbs it.

That’s the difference.

And once teams experience that shift, they rarely want to go back to pretending that standardization alone will save them.