Key Takeaways

- Most procurement leakage happens inside “acceptable” tolerances. Duplicate invoices, creeping price increases, and contract slippage often stay within rule-based limits—making them invisible to traditional controls but obvious to pattern-aware agents.

- Timing matters more than sophistication. Detecting anomalies before posting prevents downstream rework, supplier disputes, and audit noise. After posting, even the best insights arrive too late to matter.

- Duplicate detection is a behavior problem, not a matching problem. Real duplicates rarely share invoice numbers or timestamps. They repeat intent, structure, and context—signals agentic systems are designed to recognize.

- Price validation requires memory, not thresholds. Static tolerances fail in environments with negotiated uplifts, commodity-linked pricing, and plant-level variance. Agents succeed by learning what “normal” looks like over time.

- Agentic automation exposes governance gaps as much as financial ones. When agents struggle, it’s usually because policies, contracts, or master data are unclear. That friction isn’t a failure—it’s a signal the organization needs to fix upstream discipline.

Most procurement failures don’t look like failures at first.

They look like an invoice that’s slightly higher than expected. A PO that technically matches—but not quite. The duplicate invoice, arriving three weeks later with a different invoice number, manages to elude detection.

By the time finance notices, the damage is already done. Money posted. Accruals distorted. Vendor conversations are awkward. And the post-mortem always sounds the same: “The system didn’t flag it.”

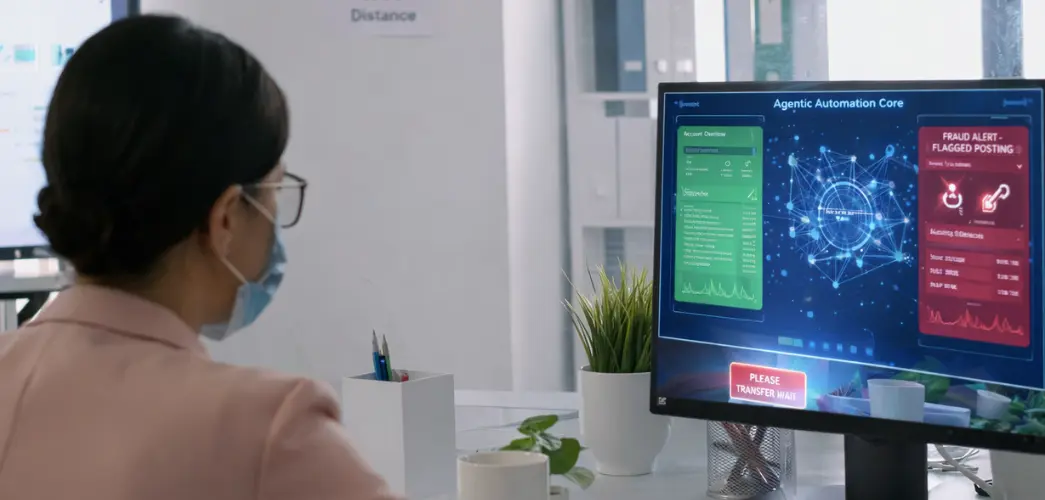

That’s the wrong diagnosis.Traditional procurement systems aren’t designed to think before posting. They’re designed to check boxes. Agentic automation changes that posture entirely. It assumes anomalies are not edge cases, but patterns waiting to be recognized—early enough to matter.

Why “Before Posting” Is the Only Moment That Matters

Once a transaction hits the ERP ledger, everything becomes harder. Corrections require approvals. Credits take weeks. Audit trails grow messy. Trust erodes quietly.

Most organizations still rely on:

- Post-posting audits

- Monthly variance reviews

- Sample-based checks

That’s fine for compliance theatre. It’s useless for leakage prevention.

Agentic automation works upstream. It watches procurement events as they form—PO creation, invoice ingestion, line-item validation—and intervenes before a transaction hardens into an accounting fact.

That temporal shift is the real breakthrough. Not AI. Not automation. Timing.

Also read: Why Procurement in Manufacturing Still Runs on Emails: A Deep Dive into Manual Vendor Management?

Duplicate Invoices: Why Rules Fail and Agents Don’t

Duplicate invoices are procurement’s oldest problem. They’re also the most misunderstood.

Most systems look for:

- Same invoice number

- Same vendor

- Same amount

That catches the lazy duplicates. It misses the real ones.

In manufacturing, duplicates hide behind:

- Split shipments billed separately

- Credit notes reissued as fresh invoices

- Same invoice resent with a suffix (“INV-1032-A”)

- Partial invoices that later get rebilled in full

- Different plants receiving identical charges for shared services

One global industrial manufacturer discovered duplicate payments weren’t coming from obvious repeats. They came from timing gaps. An invoice was submitted, parked due to GRN delay, then resubmitted weeks later when the supplier followed up. Different invoice number. Same underlying charge.

Rules couldn’t connect those dots. An agent could.

What an Agent Looks At

An agentic system doesn’t start with “Is this the same invoice?” It starts with “Does this resemble something we’ve seen before?”

Signals include:

- Similar line-item compositions

- Identical quantities across different invoice IDs

- Matching freight or tax structures

- Temporal proximity to parked or rejected invoices

- Historical supplier behavior during disputes

Sometimes it flags a “probable duplicate” with 70% confidence. Sometimes it stays quiet. And yes, sometimes it’s wrong. But that’s the point—confidence scoring beats binary failure.

When agents fail here, it’s usually because organizations starved them of history. No resolution data. No exception outcomes. Garbage memory in, garbage inference out.

Price Deviations: The Most Expensive “Small” Errors

Price deviations rarely look dramatic in isolation. That’s why they survive.

A 2% uplift on a high-volume raw material.

A freight surcharge quietly embedded in unit price.

A contract renegotiation applied to new POs but not open ones.

Procurement teams know that these things happen. Finance teams assume systems will catch them. They won’t—unless you teach them what “normal” looks like for that supplier, in that context.

Why Thresholds Are a Blunt Instrument

Most ERPs rely on static tolerances:

- ±2% price variance

- ±₹X absolute deviation

That works until it doesn’t.

Consider a casting supplier with quarterly price revisions tied to commodity indices. A flat 2% threshold either:

- Flags everything (noise), or

- Flags nothing meaningful (blindness)

Agentic automation learns price behavior over time:

- Seasonal shifts

- Volume-based discounts

- Plant-specific pricing agreements

- Temporary deviations during shortages

It doesn’t ask, “Is this outside the rule?”

It asks, “Is this inconsistent with precedent?”

That distinction matters.

Contract Violations: Where Procurement and Legal Quietly Part Ways

Contracts are precise. Procurement execution rarely is.

Contract terms say:

- Tiered pricing after volume thresholds

- Penalties for late delivery

- No charges for packaging or handling

- Fixed tax treatment by jurisdiction

Invoices say… something else.

Most violations aren’t malicious. They’re procedural drift. Suppliers billing the way they always have. Buyers approving what “looks right”. Systems matching on price and quantity, not on obligation.

Why Contract Compliance Is So Hard to Automate

Contracts are unstructured. Amendments live in email threads. Commercial terms evolve mid-year. Legal language doesn’t map cleanly to ERP fields.

Agentic automation doesn’t try to encode the entire contract. That’s a losing game.

Instead, it focuses on:

- Extracting commercial clauses that affect billing

- Monitoring deviations from agreed behavior

- Learning which clauses are frequently violated—and ignored

One electronics manufacturer found that packaging fees were contractually disallowed for strategic suppliers. Invoices included them anyway. Procurement teams manually approved them “to avoid delays”.

An agent flagged the pattern—not as a single violation, but as a recurring exception that contradicted contract norms. That led to renegotiation, not rejection. Subtle, but impactful.

How Agents Intervene

There’s a myth that agentic systems auto-block transactions. In practice, the best ones rarely do.

They intervene by:

- Pausing posting for clarification

- Routing to the right reviewer, not the default queue

- Attaching historical context to exceptions

- Suggesting likely resolutions

At times, the appropriate response is to take no action. If a price deviation aligns with a known contract uplift, the agent stays silent. Silence is a feature.

When agents overreach, it’s usually because governance is weak:

- No clear tolerance ownership

- Conflicting procurement and finance policies

- Incomplete supplier master data

Automation can’t resolve organizational ambiguity. It can only be exposed faster.

Why This Works Better Than Traditional Controls

Traditional controls assume stability. Manufacturing procurement lives in flux.

Agentic automation thrives in environments where:

- Variability is the norm

- Historical data is rich

- Exceptions repeat with variation

It doesn’t eliminate human judgment. It focuses it.

Instead of reviewing everything, teams review:

- The unusual

- The inconsistent

- The statistically improbable

That shift alone changes outcomes.

The Quiet Benefits No One Puts on Slides

Everyone talks about leakage prevention. Fair enough. But the deeper value shows up elsewhere.

- Fewer supplier disputes because issues are caught early

- Less rework in AP and procurement

- Cleaner accruals at month-end

- Auditors asking fewer uncomfortable questions

Perhaps the most underrated benefit is reduced institutional cynicism. Teams cease to operate under the assumption that “the system will inevitably fail to catch it.”

That’s cultural change. You don’t buy that with dashboards.

Where Agentic Detection Still Struggles

It’s not magic.

Agents struggle when:

- Suppliers constantly change billing behavior

- Contracts are outdated or inaccessible

- Master data ownership is unclear

- Historical exceptions were poorly resolved

In these cases, agents surface noise. That’s frustrating. It’s also diagnostic.

A Shift in Procurement Philosophy

Identifying irregularities prior to posting alters the way procurement approaches control.

It’s no longer: “Did we follow the process?”

It becomes: “Does this transaction make sense?”

That’s a higher bar. It requires context, memory, and judgement—things rules never had.

Agentic automation doesn’t replace procurement expertise. It scales it. Quietly. Relentlessly. Before money moves.

And in procurement, timing is everything.