Key Takeaways

- Automation is no longer a competitive advantage, but a baseline. By 2026, transaction-heavy and rule-stable processes are expected to be automated. Treating these wins as transformation signals a shallow digital strategy.

- Agent-led systems emerge where judgment, variability, and risk intersect. Supply chain disruptions, production replanning, and finance controls demand contextual reasoning that rigid bots cannot deliver.

- Tool-first automation limits value by scaling inefficiencies. Without redesigning decision-making, organizations simply move bottlenecks faster instead of removing them.

- A strong HyperAutomation or Agentic CoE is non-negotiable. Governance, guardrails, and ownership models determine whether agent-led systems scale responsibly or collapse under operational risk.

- Change management decides success more than technology. Manufacturers that position agents as decision partners, not replacements, build trust faster and unlock sustainable autonomy.

Walk through a modern manufacturing plant today and you’ll see a contradiction playing out in real time. On one screen, bots are flawlessly reconciling GRNs against invoices, 24/7, no complaints. On another, a production planner is still juggling exceptions through email threads, Excel trackers, and half-remembered tribal rules. Automation exists, but autonomy doesn’t. Intelligence is present, but it’s unevenly applied.

By 2026, that imbalance will no longer be sustainable.

Not because vendors say so, but because manufacturing economics are tightening from all sides: volatile demand, supplier fragmentation, skilled labor shortages, regulatory pressure, and boards asking uncomfortable questions about ROI from the last five years of “digital transformation”.

The real shift ahead is not how much gets automated. It’s what kind of work remains tool-driven and what transitions to agent-led execution.

And, frankly, many organizations are already making the wrong bets.

Also read: Supply Chain Shock Prediction Agents in Manufacturing

Automation Isn’t the Question Anymore

Most large manufacturers have crossed the automation threshold.

- RPA exists in finance and procurement

- MES systems are integrated (mostly)

- Data lakes are humming in the background

- Dashboards are everywhere, sometimes too many of them

The unresolved question isn’t whether automation works. It does. The issue is that automation has been treated as a tooling exercise rather than an operating model change.

That distinction matters.

Tool-first programs optimize tasks. Value-first programs reshape decisions.

By 2026, manufacturers that remain stuck in the former will feel it acutely.

Tool-First Thinking: Where Automation Quietly Fails

Tool-first automation usually starts with good intent.

Someone spots inefficiency. A vendor demo looks promising. A pilot is approved. Bots go live. Metrics are reported.

Then momentum stalls.

Why?

Because tool-first initiatives tend to:

- Automate isolated steps instead of outcomes

- Replicate existing process flaws at machine speed

- Depend heavily on human exception handling

- Create brittle workflows that break under real-world variability

A global automotive supplier I worked with had over 300 bots in production. Impressive on paper. Less so in practice.

In procurement alone:

- Bots created POs

- Bots validated invoices

- Bots updated ERP records

Yet buyers still spent hours daily resolving exceptions the bots escalated. Price mismatches, partial deliveries, contract nuances. The bots were obedient, not helpful.

The system worked only when reality behaved.

Manufacturing rarely does.

Value-First Thinking: A Harder, Better Question

Value-first automation starts differently.

Instead of asking, “What can we automate?” it asks:

- Where do humans still make judgment-heavy decisions?

- Which outcomes matter operationally, not just operationally easy?

- Where does variability actually create business risk?

This lens naturally leads beyond bots and toward agent-led systems.

Not because “AI agents” are trendy, but because manufacturing processes are inherently dynamic.

Demand changes. Suppliers miss deliveries. Quality issues surface late. Policies evolve mid-quarter. A rigid script cannot reason through that.

An agent can.

What Will Be Fully Automated by 2026

Some categories of work are essentially settled. By 2026, if these are still manual, it will be a leadership issue, not a technology gap.

Transaction-heavy, rules-stable activities, such as:

- Invoice matching and posting

- GRN reconciliation

- Standard journal entries

- Vendor master updates (with validations)

- Scheduled compliance reporting

- Repetitive quality data logging

These processes have three things in common:

- Clear inputs

- Deterministic rules

- Minimal contextual interpretation

Automation here should be boring. If it’s exciting, something’s wrong.

The real mistake manufacturers make is celebrating these wins as transformation.

They’re table stakes.

What Will Become Agent-Led (Whether Planned or Not)

Agent-led systems emerge where three forces collide:

- High variability

- Ongoing decision-making

- Business consequences tied to judgment

In manufacturing, this describes far more work than most leaders admit.

1. Supply Chain Exception Management

Forecasts fail. Containers get delayed. Tier-2 suppliers go silent.

Traditional automation escalates these as tickets.

Agent-led systems handle them.

An agent can:

- Assess supplier reliability history

- Recalculate downstream production impact

- Propose alternate sourcing paths

- Trigger approvals dynamically

Not replace planners, but augment their thinking.

The best implementations I’ve seen didn’t eliminate planners. They eliminated planner exhaustion.

2. Production Planning Adjustments

Static schedules don’t survive contact with reality.

By 2026, leading plants will use agents to:

- Continuously re-balance schedules based on machine health

- Factor labor availability into shift planning

- Adjust batch sizes based on real-time demand signals

The nuance here matters.

Agents don’t “optimize” blindly. They operate within guardrails defined by operations leadership. That governance layer is the difference between trust and chaos.

More on that later.

3. Finance Controls and Audit Readiness

Finance is quietly becoming one of the strongest use cases for agent-led work.

Why?

Because policies are complex, exceptions are common, and consequences are real.

An agent reviewing expense claims or CapEx justifications can:

- Interpret policy language contextually

- Flag anomalies based on behavioral patterns

- Adapt thresholds without rule rewrites

There have been audit cycles shrink not because fewer controls existed, but because agents enforced them consistently, without fatigue.

That’s not automation. That’s delegated judgment.

The CoE Gap: Why Most Manufacturers Will Struggle

Here’s the truth. Many manufacturers are trying to deploy agent-led systems without the organizational maturity required to sustain them.

The missing piece is not technology. It’s governance.

A proper Automation or Agentic CoE is not a PowerPoint artifact. It is an operating backbone.

Without it:

- Agents drift from intended behavior

- Business units deploy conflicting logic

- Risk teams panic

- IT locks everything down again

This cycle repeats across industries.

A real CoE provides:

- Decision ownership clarity

- Guardrails for autonomy

- Versioning of agent logic

- Escalation thresholds that evolve, not calcify

Most importantly, it mediates between enthusiasm and control.

Without that mediation, agent-led initiatives get quietly shelved after the first uncomfortable incident.

Change Management: The Unspoken Deal-Breaker

Manufacturing leaders often underestimate how personal this shift is. Automation threatened jobs. Agent-led systems threaten judgment.

That hits differently.

Engineers worry about being second-guessed by machines. Planners worry about losing intuition-based authority. Finance teams worry about explainability.

These concerns are not irrational.

Successful transformations acknowledge them openly.

What works:

- Positioning agents as collaborators, not replacements

- Exposing decision logic transparently

- Allowing humans to override, at least initially

- Gradually expanding autonomy as trust builds

What fails:

- Silent deployments

- Black-box reasoning

- Metrics-only success narratives

People don’t resist automation. They resist being made irrelevant without explanation.

Tool-First vs Value-First: The Fault Line of 2026

By 2026, the divide between manufacturers will be stark.

Not between those who “use AI” and those who don’t.

But between:

- Organizations that layered tools on broken processes

- And those that redesigned how decisions get made

The former will have dashboards. The latter will have resilience.

One will brag about bot counts. The other will quietly outperform peers on working capital, service levels, and margin stability.

Which side a company lands on will depend less on budget and more on mindset.

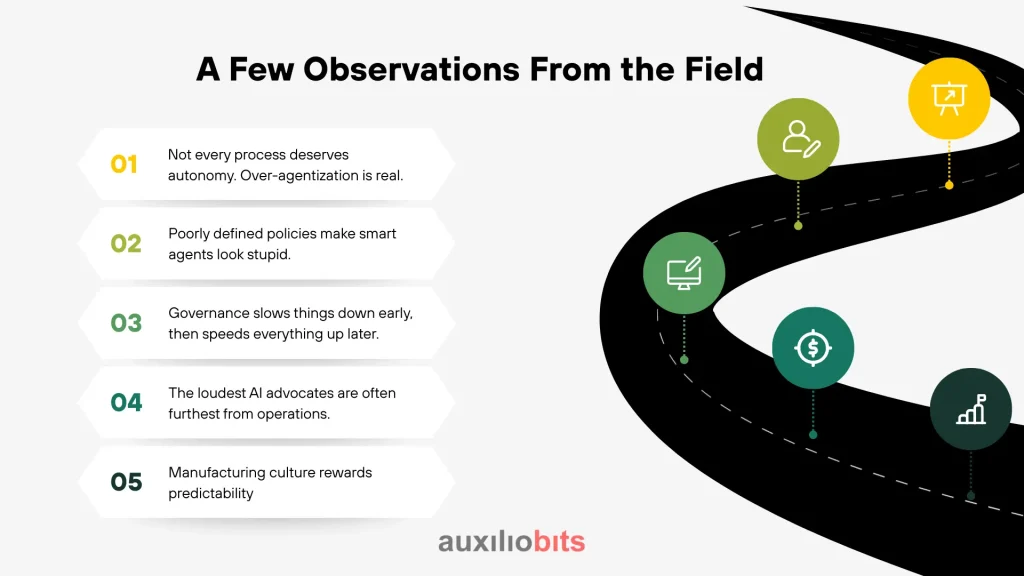

A Few Observations From the Field

Some truths that don’t make it into vendor decks:

- Not every process deserves autonomy. Over-agentization is real.

- Poorly defined policies make smart agents look stupid.

- Governance slows things down early, then speeds everything up later.

- The loudest AI advocates are often furthest from operations.

- Manufacturing culture rewards predictability. Agentic systems introduce managed uncertainty. That tension must be handled, not ignored.

Ignoring these realities doesn’t make them disappear. It just delays the reckoning.

Where This Is Actually Headed

By 2026, the most effective manufacturing organizations will look subtly different.

Fewer heroics. Fewer late-night escalations. Fewer “how did this slip?” moments.

Not because humans stopped caring.

But because machines took on the cognitive load they were never meant to carry indefinitely.

Automation will handle the known. Agents will handle the changing. Humans will handle the accountable.

That division of labor isn’t futuristic. It’s overdue.

The only real question is whether manufacturers choose it deliberately, or stumble into it after the old model finally breaks.

And it will break. The warning signs are already there.