Key Takeaways

- Automation is largely a solved problem; decision-making is not. By 2026, competitive advantage comes less from automating tasks and more from how intelligently decisions are prepared, challenged, and executed.

- Heatmaps expose where money and attention are actually leaking. The most valuable opportunities sit in medium-variance, exception-heavy zones where classic automation stalls and agent-led systems add leverage.

- Agent-led systems work best as collaborators, not replacements. Their real value lies in narrowing cognitive gaps—surfacing patterns, scenarios, and trade-offs—while humans retain accountability.

- Human roles are shifting upward, not disappearing. Judgment moves from transaction handling to cross-functional arbitration, risk balancing, and outcome stewardship.

- Manufacturing maturity in 2026 will be measured by balance. Not how much is automated, but how well automation, agents, and humans are orchestrated across the enterprise.

Manufacturing leaders like to say they’re “already automated.” And in a narrow sense, that’s true. GRN matching runs overnight without human eyes. Production schedules are generated by APS engines. Quality data flows into dashboards faster than anyone can read it.

Yet when you map where time, money, and cognitive load actually go inside a manufacturing enterprise, the picture changes. A heatmap of operational effort tells a more honest story. It highlights where automation is saturated, where it delivers diminishing returns, and where something else—call it agent-led work—starts to matter more.

Looking toward 2026, the question is no longer what can be automated. That list is mostly known. The real question is what should be automated, what should be delegated to autonomous agents, and where humans remain essential—not as exception babysitters, but as decision-makers with context and judgment.

This forecast isn’t vendor-driven optimism. It’s based on patterns that show up repeatedly when you plot process complexity against variability, financial impact, and decision latency.

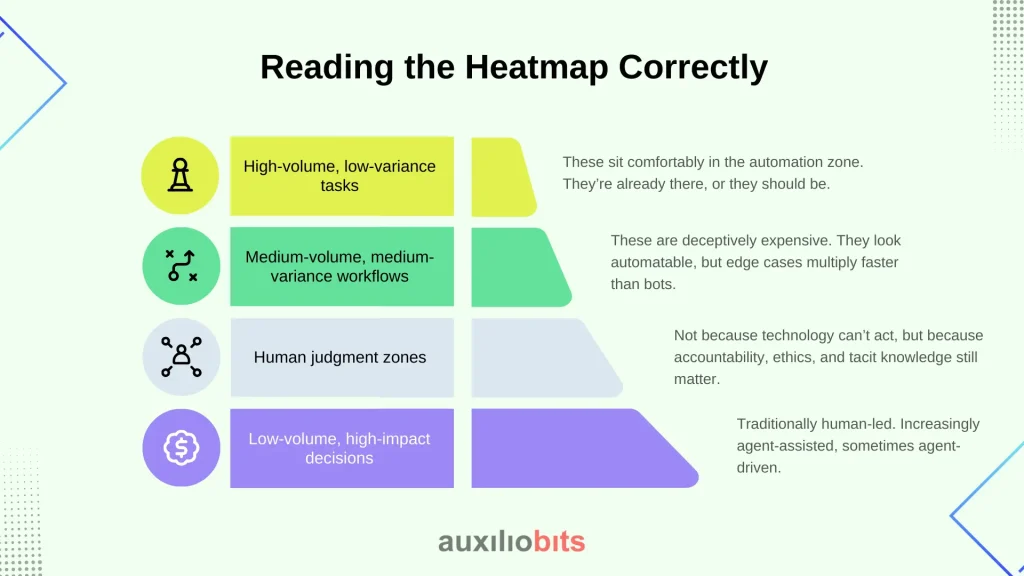

Reading the Heatmap Correctly

A process heatmap isn’t a technology roadmap. It’s a friction map. Across manufacturing organizations we see four recurring bands:

- High-volume, low-variance tasks: These sit comfortably in the automation zone. They’re already there, or they should be.

- Medium-volume, medium-variance workflows: These are deceptively expensive. They look automatable, but edge cases multiply faster than bots.

- Low-volume, high-impact decisions: Traditionally human-led. Increasingly agent-assisted, sometimes agent-driven.

- Human judgment zones: Not because technology can’t act, but because accountability, ethics, and tacit knowledge still matter.

The 2026 shift isn’t about pushing everything up the automation curve. It’s about redistributing intelligence across these zones.

Also read: Integrating RPA, AI and Process Mining for Manufacturing Success

What Will Be Fully Automated by 2026

Let’s begin by addressing the obvious. Certain areas will continue to consolidate under classic automation and rules-based AI, and frankly, there’s little debate left.

1. Transactional Finance Operations

The heatmap here is already cool—low friction, high maturity.

- Invoice ingestion, three-way matching, tax validation

- Standard accruals and journal postings

- Payment runs and remittance advice

- Fixed asset capitalization with predefined thresholds

The economics are settled. These processes are structured, audited, and intolerant of creativity. Humans slow them down.

Where some manufacturers still hesitate, it’s usually due to legacy ERP customizations or historical fear of audit risk. Both are solvable. By 2026, tolerance for manual handling here will be seen as operational negligence, not caution.

2. Master Data Synchronization

Once treated as sacred human territory, now steadily automated:

- Material master updates across plants

- Vendor master creation with policy enforcement

- BOM version propagation

The trick has been validation, not entry. As reference data quality improves and controls become embedded, the heatmap shifts decisively toward automation. Human review becomes sampling-based, not transactional.

2. Machine-Level Quality Data Capture

Sensors don’t argue. Machines don’t forget.

- SPC data ingestion

- Automated alerts for threshold breaches

- First-pass yield reporting

What used to require clipboards and end-of-shift reconciliation is now event-driven. By 2026, any plant still manually aggregating this data will be doing so by choice, not necessity.

Where Automation Plateaus and Agent-Led Systems Take Over

This is where the heatmap gets interesting. These zones glow hot not because nothing works, but because too many things partially work.

1. Procurement: From PO Factories to Negotiation Intelligence

PO creation? Automated. Approval routing? Automated. That part is done.

What still burns time and margin:

- Supplier exceptions

- MOQ conflicts

- Price variance explanations

- “Temporary” deviations that last six months

Traditional automation breaks here because rules explode combinatorially. Agent-led systems, however, can:

- Monitor supplier behavior patterns

- Proactively flag when negotiated terms drift

- Simulate cost impact before humans escalate

Not fully autonomous procurement—yet. But agents increasingly prepare decisions, not just execute tasks.

Humans still negotiate. Agents do the math, track the history, and surface the leverage points.

2. Supply Chain Planning Under Volatility

Forecast engines have existed for decades. The heatmap shows they’re necessary but insufficient.

Where friction remains:

- Demand shocks

- Supplier reliability fluctuations

- Cross-plant capacity trade-offs

An agent-led approach doesn’t replace planners. It shadows them.

- Running parallel scenarios continuously

- Watching for weak signals humans miss

- Recommending plan adjustments with rationale, not just numbers

In 2026, planners who rely only on static monthly cycles will feel blind. Those working with agentic systems will feel augmented—and occasionally challenged.

And yes, sometimes the agent will be wrong. That’s fine. The value is in narrowing the cognitive gap, not eliminating human oversight.

Maintenance: Beyond Preventive, Not Fully Autonomous

Predictive maintenance has been oversold, then underdelivered. The heatmap explains why.

- Sensor data is abundant

- Failure modes are contextual

- Maintenance windows are political

Agent-led maintenance systems excel at correlation and early warning. They struggle with organizational constraints.

By 2026, expect:

- Agents recommending maintenance timing based on production plans

- Automated work order drafts with risk scoring

- Human supervisors making final calls

The machine doesn’t decide when to stop a line. It makes the cost of not stopping painfully explicit.

Where Humans Still Matter (And Will Continue To)

There’s a temptation to frame this as a shrinking human role. That’s inaccurate. The heatmap doesn’t show humans disappearing; it shows them moving.

1. Cross-Functional Trade-Offs

No system—agent or otherwise—truly owns enterprise-wide priorities.

Examples that resist full automation:

- Expedite an order at the cost of supplier goodwill

- Delay a shipment to protect quality reputation

- Accept short-term margin erosion to secure long-term capacity

These decisions require context beyond data. Politics, brand, relationships. Humans arbitrate here because responsibility cannot be abstracted away.

2. New Product Introduction (NPI)

Agents can simulate. They can validate BOMs. They can check routings.

What they can’t do alone:

- Interpret ambiguous requirements

- Balance speed against manufacturability risk

- Sense when a design “feels” fragile based on experience

By 2026, agents will accelerate NPI cycles. They won’t own them.

The Heatmap Forecast: Department by Department

Rather than abstract trends, here’s how the distribution typically looks when you overlay effort, complexity, and value.

Finance

- Automated: Transaction processing, reconciliations

- Agent-led: Cash forecasting, working capital optimization

- Human-led: Capital allocation, risk appetite decisions

Supply Chain

- Automated: Order execution, ASN processing

- Agent-led: Network optimization, scenario planning

- Human-led: Strategic sourcing, geopolitical risk response

Operations

- Automated: Data capture, basic scheduling

- Agent-led: Capacity balancing, constraint analysis

- Human-led: Line leadership, workforce decisions

Quality

- Automated: Inspection data, deviation logging

- Agent-led: Root cause pattern detection

- Human-led: Release decisions, customer-facing quality responses

The pattern repeats. Automation handles certainty. Agents handle complexity. Humans handle accountability.

When Agent-Led Systems Fail

There’s value in discussing failure modes, because ignoring them leads to mistrust.

Agent-led approaches stumble when:

- Data lineage is unclear

- Organizational incentives conflict

- Humans abdicate judgment instead of engaging

By 2026, mature manufacturers will treat agent recommendations as arguments, not commands. The dialogue matters.

Outcome Stewardship: Moving Beyond Process Ownership

One underappreciated change the heatmap reveals is cultural.

People stop “owning” processes and start stewarding outcomes.

- Fewer clicks, more questions

- Less firefighting, more framing

- Accountability shifts upward, not outward

This is uncomfortable. Some roles dissolve. Others become more demanding cognitively, even if fewer hands touch the keyboard.

Not everyone welcomes that. Adoption friction is rarely technical.

Final Thought

There is no denying that manufacturing in 2026 won’t feel dramatically different on the surface. Plants will still hum. ERPs will still run. Dashboards will still glow.

The difference is evident in where attention is directed.

Less time spent correcting what machines already know how to do. More time spent deciding what should be done when the data points in conflicting directions.

Automation cools the heatmap. Agent-led systems redistribute the heat. Humans decide where to apply pressure.

That balance—not full autonomy—is what defines the next phase.