Key Takeaways

- Infor ERP excels at structured operations but struggles with dynamic logistics. Manufacturing teams often rely on spreadsheets and manual decision-making because transportation planning falls outside ERP rigidity.

- CrewAI Planners bring situational intelligence to Infor workflows. They don’t just automate clicks—they interpret data, assess context, and propose or execute decisions autonomously.

- Clean data is non-negotiable. Without accurate master data, even the most advanced AI agents amplify confusion instead of reducing it.

- Automation enhances, not replaces, planners. CrewAI lets logistics teams shift from reactive firefighting to proactive management—handling more volume with better accuracy.

- Incremental deployment drives success. Start small, capture exceptions, and evolve the system through feedback—sustainable automation emerges from steady learning, not overnight overhaul.

You can usually tell when a company has grown faster than its systems. Walk into any medium-sized manufacturing plant and you’ll see it—the production floor looks modern, but somewhere in the corner, someone is still updating delivery schedules in Excel. And more often than not, that’s sitting on top of Infor ERP.

Infor’s ecosystem is incredibly capable—CloudSuite, LN, M3, all of it. But anyone close to an implementation knows that while Infor handles materials, inventory, and production scheduling beautifully, logistics is where the human glue starts showing. Transportation planning, carrier coordination, and route optimization don’t always fit neatly into Infor’s process boxes.

What most teams do is improvise. And honestly, it works… until it doesn’t.

Also read: Creating the Digital Nerve Center of Tomorrow with Agentic Workflows

Where Infor Leaves Planners Hanging

Infor’s workflows are fantastic when everything follows the plan. The moment production shifts, a supplier runs late, or a carrier misses a pickup, the whole thing starts to wobble.

There have been teams that handle dispatch schedules on color-coded spreadsheets because the ERP’s transport module felt “too rigid.” They export, re-import, email, and call—and by the time it’s all synced back into Infor, half the assumptions are outdated.

Common issues pop up repeatedly:

- Transport triggers aren’t automatic. Someone still clicks through menus to mark orders as ready.

- Carrier assignment is manual, usually based on habit, not data.

- Route optimization? Usually, a quick Google Maps check and a gut decision.

- Shipment confirmations arrive too late to correct anything meaningful.

Infor was built for order precision, not dynamic transport optimization. That’s not a design flaw—it’s just reality. But it’s also exactly where CrewAI Planners start earning their keep.

The Point of Adding CrewAI

CrewAI Planners aren’t another dashboard or reporting plugin. They’re agents—decision layers that sit quietly between your ERP and real-world movement. Instead of just automating clicks, they interpret events and respond with judgment.

When you integrate CrewAI into your Infor workflows, you’re basically giving the ERP something it’s never had before: situational intelligence.

Here’s what that looks like in practice:

- A production order closes in Infor. CrewAI detects the event and automatically checks which shipments are affected.

- It validates stock levels, delivery priorities, and current carrier availability.

- It runs its optimization logic—not just the cheapest route, but feasible ones, considering driver hours, local regulations, and even weather when possible.

- It proposes the best plan—or just executes it if pre-approved.

- Then, it updates the ERP automatically, ensuring traceability stays intact.

Instead of waiting for humans to interpret ERP reports, CrewAI makes Infor behave more like a decision-making partner.

A Reality Check

Automation isn’t a silver bullet. The first thing I tell clients is that if your data hygiene is poor, no AI layer will save you. Garbage in, garbage out—the old saying is truer than ever.

That said, when your master data is decent, CrewAI gives logistics teams something they’ve been missing: time. Planners stop firefighting and start managing. They can see trade-offs before making a call instead of reacting after the fact.

One manufacturing client started small—just automating dispatch grouping between their M3 system and their 3PL. Within two months, shipment planning time dropped from 2.5 hours to about 20 minutes. No one was laid off; the same team just handled 3x the volume with better accuracy.

When you walk into their control room now, the planners aren’t glued to spreadsheets. They’re reviewing CrewAI’s route proposals, adjusting when needed, and moving on. It’s a small but meaningful cultural shift—from manual coordination to supervised automation.

The Integration Anatomy

Here’s what’s technically happening under the hood, though most of it doesn’t require heavy lifting once set up:

- Infor Triggers: Events like “production order complete” or “delivery ready” are exposed through Infor ION APIs.

- CrewAI Receives: The agent listens for those triggers and fetches relevant data—order details, item weights, and customer delivery SLAs.

- Optimization Run: CrewAI runs its optimization script (many use constraint solvers similar to OR-Tools, tuned for logistics).

- Decision Pushback: It posts planned dispatches or suggested carriers back into Infor’s transport workflow.

- Continuous Learning: Over time, the AI notices recurring bottlenecks—maybe a certain carrier causes delays every Friday—and starts adjusting automatically.

Infor remains the system of record. CrewAI becomes the system of reasoning.

Where It Works (and Where It Struggles)

Automation thrives in repetitive processes. If your dispatches follow consistent rules—weight thresholds, carrier zones, delivery frequency—CrewAI can take over 70–80% of decisions confidently.

But here’s the nuance: automation breaks when judgment is still tribal knowledge. If one planner knows that a certain carrier only picks up after 5 PM because of local traffic, and that’s never logged anywhere, CrewAI can’t learn it yet.That’s why the most effective deployments build feedback loops. CrewAI might propose a plan, but if the human overrides it, they’re prompted to record why. Over time, those exceptions become new rules, and the system gets smarter without being brittle.

A Few Field Lessons

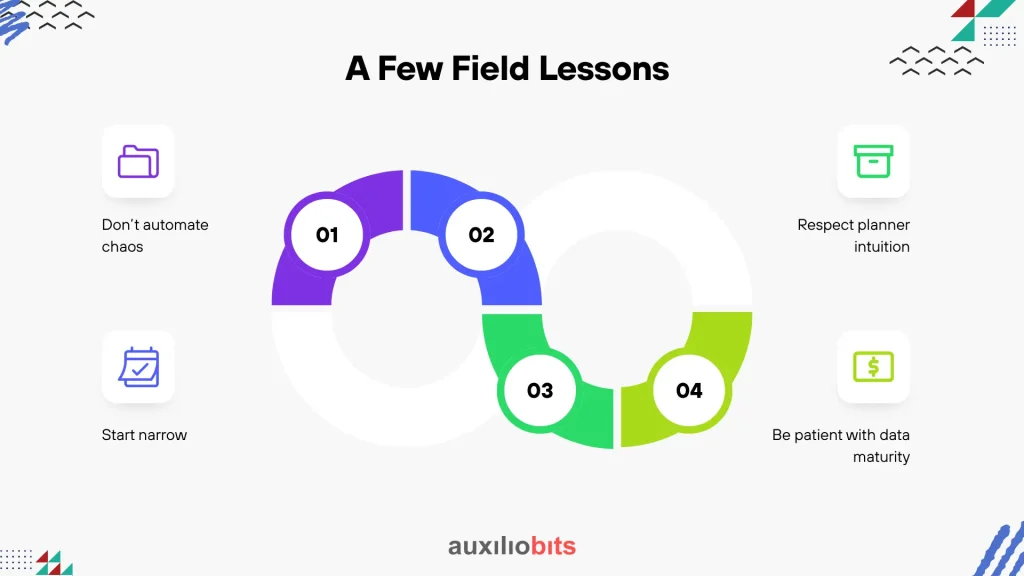

After seeing half a dozen implementations, a few truths stand out:

- Don’t automate chaos. If your transport master data is messy, fix that first. AI will only multiply the confusion.

- Start narrow. One process, one facility. Get it stable before scaling.

- Respect planner intuition. Some overrides aren’t “mistakes”; they’re micro-corrections from experience. Capture them.

- Be patient with data maturity. The first few weeks often produce noisy recommendations. Give the AI time to calibrate.

The manufacturers who understood this saw the best ROI — not in weeks, but in sustained performance after 3–4 months.

A Few Examples That Speak Volumes

1. Automotive Supplier, Germany: Integrated CrewAI with Infor LN to automate outbound scheduling.

- Result: 15% increase in on-time shipments; dispatch coordination time dropped from 2 hours to 30 minutes.

2. Industrial Packaging Firm, Malaysia: Used CrewAI to dynamically assign carriers based on historical reliability and lane data.

- Result: Transport spending reduced by 8.6%, fewer delivery disputes.

3. Heavy Equipment OEM, U.S.: CrewAI validated customs documentation automatically before container dispatch.

- Result: Cut export delays by nearly a quarter.

None of these were massive overhauls. They were incremental, well-scoped automations layered over Infor’s existing logic.

When to Roll It Out

You shouldn’t rush into CrewAI just because it’s trendy. Wait until:

- Your Infor ERP modules are stable and routinely used across teams.

- Transport planning is a measurable pain point — delays, cost variability, and overworked schedulers.

- You can quantify potential gains: saved hours, reduced manual entries, and fewer missed SLAs.

- You have someone on the ground who understands both logistics and data integration.

Otherwise, you’ll spend more time firefighting than improving.

A Subtle Perspective Shift

Automation done right doesn’t remove the human—it frees them to think. The Infor system will always be your source of truth, but truth alone doesn’t plan a route or decide which carrier to trust on a rainy Thursday. That’s where the intelligence layer makes a difference.

CrewAI doesn’t make manufacturing logistics futuristic; it makes them functional. It bridges the messy gap between perfect ERP data and the imperfect world of moving trucks, shifting schedules, and unpredictable delays.

At its best, it gives teams something they rarely have enough of: clarity.

And in logistics, clarity often beats speed.

Conclusion

Transportation optimization inside Infor ERP was never meant to be effortless—it’s a dynamic, judgment-heavy function sitting at the crossroads of production, inventory, and customer commitment. What CrewAI Planners bring to this landscape is not a replacement for human expertise, but an amplification of it. They give Infor workflows the ability to think in context, to interpret rather than just execute.

The real transformation doesn’t come from eliminating human touch—it comes from elevating it. When planners spend less time on clicks and corrections, they gain more bandwidth for scenario thinking, carrier strategy, and performance improvement. Over time, CrewAI turns transport coordination from a reactive chore into a predictive discipline.

For manufacturing teams running on Infor ERP, the lesson is simple: automation isn’t about building a smarter system—it’s about creating a more adaptive organization. The plants that embrace incremental intelligence, clean data, and human-AI collaboration won’t just optimize shipments; they’ll redefine what operational precision feels like.