Key Takeaways

- Automation doesn’t fix disorder—it magnifies it. If processes vary wildly across teams or regions, bots and AI agents will stumble.

- Standardization isn’t bureaucracy—it’s engineering discipline. Aligning inputs, fields, and exception rules is what makes automation scalable.

- Resistance is natural. Staff push back against standardization more than automation; leaders need to frame it as the path to less drudgery, not more rules.

- Balance matters. Standardize transactional, data-heavy steps while preserving flexibility where human judgment or empathy is essential.

- Shortcuts backfire. Interim “messy automations” may be unavoidable during transitions, but treating them as permanent solutions creates long-term fragility.

The automation market is overflowing with promises. Slide decks show bots slashing costs, AI agents speeding up workflows, and dashboards lighting up with efficiency gains. The reality, though, is far less glossy. Many organizations launch automation initiatives only to discover that their underlying processes are riddled with inconsistencies. One region logs data differently, another skips steps entirely, and a third has a dozen undocumented workarounds. When you try to automate that kind of landscape, you don’t get efficiency—you get accelerated chaos.

Which is why standardization, however tedious it sounds, is the first job. If you skip it, you’ll spend more money debugging bots than the processes ever cost in the first place.

Also read: Designing LLM-Based Process Assistants with Task-Level Context

Why Standardization Isn’t a Nice-to-Have

People tend to view process standardization as bureaucratic overhead. Something consultants love because it means more workshops and documentation. But talk to any IT leader who’s lived through a failed RPA rollout, and you’ll hear the same refrain: the automation wasn’t the problem; the inconsistency was.

Take invoice processing. If Group A accepts scanned PDFs, Group B insists on paper copies, and Group C uses Excel attachments, what exactly are you automating? The bot either needs three separate pathways or an ever-growing library of exception-handling rules. That’s not automation—it’s duct tape.

By contrast, if everyone agrees on a single intake format and validation sequence, the automation can be built once and reused everywhere. The business case finally holds.

The Hidden Cost of Skipping Standardization

Time back, a healthcare provider attempted to roll out automated patient intake across its network of clinics. On paper, it was a simple workflow: capture demographics, verify insurance, log allergies, and generate an admission number. Straightforward enough. Except, in practice, each clinic had designed its own version of the intake form.

- Some asked about allergies at the start, others at the end.

- Several used drop-down menus, while a few still typed everything manually.

- One site required a physician’s sign-off before generating an ID; others didn’t.

The automation team found itself coding exceptions for exceptions. After months of rework, the project was shelved. The cost of harmonizing intake workflows after the fact exceeded the original automation budget. Only later, after leadership pushed through a standardized intake form across all facilities, could automation be reintroduced successfully.

That’s the risk: automation makes hidden variation painfully visible, and by then you’re bleeding money.

What Standardization Really Means

Too often, standardization is confused with rigid scripting of every keystroke. That’s not the point. The goal is to remove needless variation so machines can follow logic consistently. Think of it as creating “shared grammar” for the process.

It usually involves:

- Clear input definitions. Decide which formats are acceptable. Ban the rest.

- Unified data fields. A customer number is either numeric or alphanumeric, but not both.

- Agreed sequencing. Even if humans can adjust orders on the fly, bots don’t improvise.

- Exception handling rules. Document how edge cases are treated and who steps in when things fall outside the boundary.

It’s more about discipline than bureaucracy. Machines need rules, and standardization is how you supply them.

The Cultural Hurdle

Ironically, employees often resist standardization more than automation itself. Automation feels exciting, futuristic, and maybe even prestigious. Standardization? That feels like head office meddling in the details.

Entire teams argue passionately that their quirks are critical. A procurement manager once told me, “We have to allow manual vendor codes because our suppliers are different.” When we compared practices across regions, it turned out the difference wasn’t in suppliers at all—it was simply habit.

Resistance eases when leaders frame standardization as the enabler for automation. If staff understand that agreeing on a single workflow will let the bots take over their repetitive tasks, they become more willing to compromise. Otherwise, it feels like rules for the sake of rules.

Industry Context: Where Standardization Matters Most

Some industries can get away with a little inconsistency. Retail promotions, for example, often thrive on creative variation. But in regulated, high-stakes sectors, the lack of standardization can cripple automation efforts.

- Banking: Know Your Customer (KYC) checks vary wildly across branches. Without uniform rules, automating compliance is impossible.

- Manufacturing: Vendor onboarding often differs plant by plant, leading to dozens of redundant automation builds.

- Insurance: Claims intake varies by line of business. If you don’t harmonize what “complete documentation” means, bots constantly stall.

- Healthcare: Regulatory reporting requires precise formats. Even small variations in how data is logged can create non-compliance risks.

These industries are also the ones most eager to automate. The irony is that their very complexity makes automation fragile without upfront standardization

Where to Standardize, Where to Allow Flexibility

Here’s the nuance: not every process benefits from being standardized. Customer service scripts, for instance, often require flexibility to handle human emotion. Lock them down too tightly, and you get robotic interactions that frustrate customers.

So, what should you standardize? Anything transactional. Data entry, document validation, approvals, and system handoffs—these thrive on consistency. What should you protect from over-standardization? Human judgment, discretionary decisions, and customer-facing empathy.

It’s a balancing act. Err too far one way, and you get rigid processes that alienate staff. Lean too far the other way, and your automation collapses under the weight of exceptions.

A Practical Litmus Test

One question we often pose to leadership teams: Could a brand-new hire execute this process without improvising?

If the answer is yes, you’re close to ready for automation. If not—if the process relies heavily on tribal knowledge or “the way Susan does it”—then you’ve got work to do. Standardization doubles as documentation. It forces tacit knowledge into explicit rules. Without that, you’re building bots on shaky ground.

Manufacturing Example: Order Validation Woes

A global manufacturer tried to automate its order-to-cash cycle. The sticking point was order validation. Bots failed repeatedly, and IT couldn’t understand why.

After review, they found:

- Europe required VAT checks upfront.

- North America did the post-shipment.

- Asia ignored VAT but insisted on cross-referencing every PO.

From a human perspective, these variations had been manageable. From an automation perspective, they were impossible. The fix wasn’t technical—it was organizational. Only after harmonizing the definition of a “valid order” could the bots run smoothly.

It’s a stark reminder: automation uncovers the cracks you’ve been papering over.

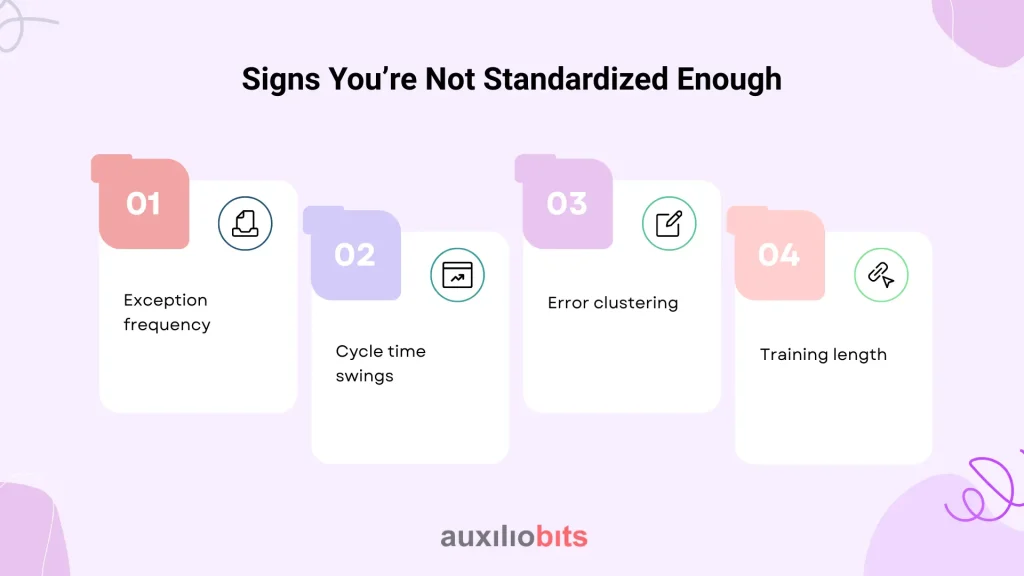

Signs You’re Not Standardized Enough

Before throwing money at automation, check a few indicators:

- Exception frequency. If more than a fifth of cases need manual intervention, automation will choke.

- Cycle time swings. If the same task takes 2 hours in one branch and 2 days in another, the variation is too high.

- Error clustering. When errors spike in particular regions or teams, it’s often due to inconsistent practices.

- Training length. If new hires need months to learn a process, it’s probably too dependent on personal tricks and workarounds.

These aren’t just operational annoyances—they’re signals that your foundation isn’t ready for automation.

Why Leaders Jump Ahead Anyway

So why do executives keep greenlighting automation before standardization? Partly, it’s the way vendors sell. The demos are dazzling: bots flipping through invoices, AI assistants answering queries in seconds. No one demonstrates the months of cross-department workshops needed to agree on invoice formats.

The other reason is pressure. Shareholders and boards want quick wins. Standardization sounds slow, political, and dull. Automation sounds fast, modern, and bold. The mismatch is predictable. Too often, projects launch under pressure and collapse under complexity.

When You Can’t Standardize Immediately

There are moments when standardization isn’t feasible in the short term. Mergers and acquisitions are classic examples. Two companies with different ERP systems can’t harmonize overnight. In those situations, tactical automation—messy though it is—might be justified as a bridge.

But don’t confuse a bridge with a highway. Stopgap automations are brittle, and if they linger too long, they calcify into the operating model. IT ends up managing hundreds of fragile bots built on sand. That’s not transformation—it’s technical debt in disguise.

Technology as an Enforcer

Some organizations try to enforce standardization through tools. A workflow system that forces users to pick from a controlled list, or a data lake that rejects incomplete records, can push consistency. These guardrails help, but only if the culture supports them.

I’ve seen cases where the official system required certain fields, but employees kept a side spreadsheet with their “real” data. Technology can’t fix willpower problems. Leadership commitment is still the hinge.

Hard Truths for Executives

- Automating broken processes doesn’t save money—it burns it faster.

- Standardization feels slow, but it accelerates automation in the long run.

- Employees will resist until they see the upside. Don’t skip the storytelling.

- Some variation is healthy. The art lies in knowing which parts to harmonize and which to leave flexible.

- Stopgap automations are fine as long as you treat them like temporary scaffolding, not permanent infrastructure.

Closing Reflection

Automation has been on every board agenda for years. Yet if you trace why so many programs stall, the answer isn’t usually technology. It’s the lack of shared process discipline. Standardization is tedious. It rarely gets celebrated. But it’s the difference between an automation strategy that scales quietly across the enterprise and one that collapses after a few flashy pilots.

So, if your teams can’t yet agree on how the work is done today, ask yourself: why would a machine do any better tomorrow?