Key Takeaways

- End-to-end is a design choice, not just scale – True enterprise automation succeeds when processes are viewed holistically across handoffs, not as isolated steps.

- Current-state mapping is critical – Relying solely on vendor templates leads to blind spots; mapping hidden workarounds and shadow systems reveals the real process bottlenecks.

- Multi-dimensional prioritization drives better ROI – Value should be assessed across dependencies, data readiness, and cultural adoption, not just effort versus impact.

- Governance and architecture are strategic levers – Strong governance structures and composable, loosely coupled architecture ensure automation efforts scale sustainably.

- Culture and continuous monitoring ensure compounding value – Automation-first thinking, paired with outcome monitoring, transforms automation from one-off efficiency gains into long-term enterprise advantage.

Thirty months ago, a large insurance provider launched what they called “a full-scale automation initiative.” They started with enthusiasm (and a budget that would make even the CTO smile)—RPA bots for policy administration, a contract with a process-mining vendor, and a few pilot conversations about AI-driven underwriting. Twelve months later, 8 of the 11 bot implementations were paused, and the central automation CoE had quietly folded into their corporate IT team. The lesson: automation technologies on their own do very little. Strategy, on the other hand, is what differentiates for—and against—outcome.

Let’s now learn about the essential steps required to build an end-to-end automation strategy for enterprise efficiency.

Also read: Insurance Broker Portals: End-to-End Quote-to-Bind Automation

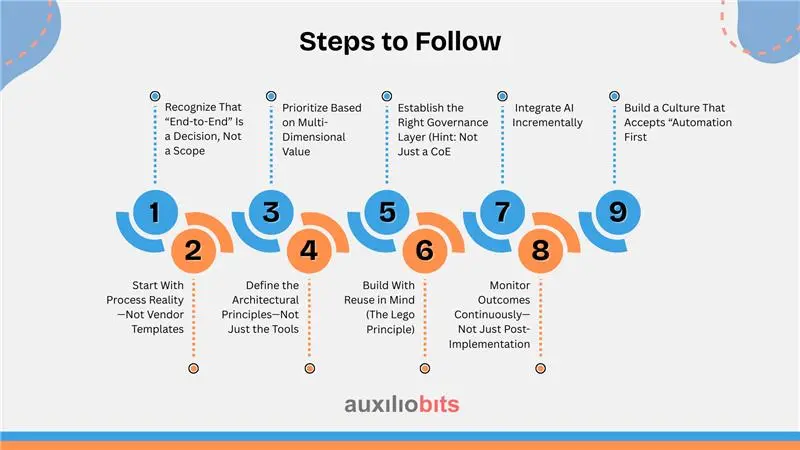

Steps to Follow

Step 1. Recognize That “End-to-End” Is a Decision, Not a Scope

Some organizations still use the term “end-to-end” to essentially mean “big.” That’s a mistake. In automation, “end-to-end” is not about sheer scope—it’s about designing with the flow of work in mind:

- Order-to-cash becomes fragmented the moment quoting, order entry, fulfillment, and billing are treated as separate tech domains.

- Procurement remains sluggish when vendor onboarding is automated, but approvals still need three manual email follow-ups.

Example: Over the past year, a mid-sized manufacturing company learned this the hard way. They automated their warehouse dispatch process while leaving order confirmation untouched. The result: automated dispatches that were still waiting for manually uploaded order confirmations, creating two days of dead time in the middle of a supposedly automated process.

Step 2. Start With Process Reality—Not Vendor Templates

Every major automation vendor now markets “best-practice accelerators” (digital twin templates, mortgage underwriting blueprints, and healthcare bundle libraries). These are useful references, not starting points.

A smarter approach is to map the actual current-state workflow, including:

- Shadow systems (yes, the Excel file someone keeps updating in the background every Friday)

- Workarounds (“We print this report because our ERP doesn’t allow batch download”)

- Hidden approval steps (“Mike always looks at these forms before finance signs off—we don’t document it officially”)

Example: A global logistics provider spent three months mapping their freight invoicing process using a vendor accelerator. Once the bots went live, they discovered two undocumented manual checks performed by the regional compliance team. Those checks caused 20% of the invoices to fall out of the automated flow immediately—even though the “official” process map looked complete.

Step 3. Prioritize Based on Multi-Dimensional Value

A lot of roadmaps use simple matrices: low effort / high impact vs high effort / low impact. These are perfectly fine for tactical decisions. But strategy calls for something more nuanced.

An end-to-end automation prioritization model should include factors like:

- Cross-process dependency (Does automating this step unlock downstream value?)

- Data maturity (Do we have clean, structured data for this step, or will we spend three months on basic extract/transform/clean?)

- Change fatigue in the department. (Sometimes the process is perfect for automation—but the users have already dealt with two new tools this year and will actively resist a third.)

- AI-adjacency (Is the process ready to take advantage of autonomous agents or intelligent decisioning once basic automation is in place?)

Example: One large bank prioritized fraud alert triaging because it had high volume — only to realize the data quality was so inconsistent that model training was practically impossible. Meanwhile, a slightly less glamorous reconciliation step downstream would have delivered immediate value and could’ve been used as a foundation to build intelligent fraud detection two quarters later.

Step 4. Define the Architectural Principles—Not Just the Tools

A real automation strategy starts with architectural principles, such as:

- Single event-driven workflow layer

- Loose coupling between systems

- Agent orchestration capability (bots/tasks should be orchestrated, not manually triggered)

- Ability to inject AI decision-making without altering the process logic

Example: Some time back, a provider built a low-code-based referral-management flow with complex embedded manual triggers. Six months later, when they tried to inject a triage classification model, they discovered they had to re-architect almost 60% of the flow. The problem wasn’t the technology at all — it was the lack of foundational architectural thinking.

Step 5. Establish the Right Governance Layer (Hint: Not Just a CoE)

End-to-end automation requires two distinct structures:

| Layer | Purpose |

| Automation CoE | Methodology, reuse patterns, tools, and platform ownership |

| Business Process Council | Process ownership, outcomes, prioritization, boundary setting |

Example: A manufacturing conglomerate adopted this two-layer governance model and saw something interesting: the Business Council canceled one of its high-priority requests after realizing it conflicted with another department’s downstream flow. That decision saved six months of rework—the CoE alone would never have caught it.

Step 6. Build With Reuse in Mind (The Lego Principle)

Better approach: treat workflows like composable blocks that can be reused across processes or departments.

Examples:

- A “vendor onboarding bot” is 40% identical to a “supplier profile update bot.”

- Customer order validation, vendor invoice validation, and expense claim validation can reuse the same document classification model with minor tweaks.

Example: One insurance company built a modular document-classification framework once and reused it across underwriting, claims intake, and policy amendments. The effort saved them nearly $800 in avoided third-party integrations over eighteen months.

Step 7. Integrate AI Incrementally

Some AI components (like document extraction, anomaly detection, or recommendations) can be embedded very early, while full agentic flows should come only after a stable, automated process baseline is in place

| Layer | Example |

| Assisted automation | Human triggers bot; bot executes task |

| Embedded AI | Bot calls ML model for classification/decision |

| Agentic flow | AI agent orchestrates the entire process end-to-end |

Example: A large logistics player started with basic OCR for transport orders, then layered on route-optimization models, and finally released an AI agent to autonomously schedule delivery runs. Each phase built on the previous one. If they had tried to go directly to the agentic layer, the whole program would likely have fallen apart.

Step 8. Monitor Outcomes Continuously—Not Just Post-Implementation

Once the automation is deployed, everybody tends to relax. “We’ve gone live.” A bank experienced exactly that. In the first 9 months, straight-through-processing increased from 43% to 71%. But nobody noticed that the exception queue started growing steadily. It took a manual audit to realize that small changes in upstream data formatting had introduced slow, compounding errors into the workflow. An always-on monitoring framework would have flagged the issue within days.

Step 9. Build a Culture That Accepts “Automation First”

Automation-first culture means:

- Teams expect the process to work without human involvement (and escalate only when needed)

- New processes are designed assuming automation is the default execution method.

- Exceptions are viewed as design flaws, not as normal.

- Teams proactively suggest new automation opportunities without waiting for an annual planning cycle.

Example: A well-known healthcare network in the Northeast ran a campaign internally called “Default to Automated.” They trained staff to treat manual intervention as an exception that needed a justification. Within eight months, unsolicited automation suggestions from process owners outnumbered those from the CoE by three to one—and the overall automation pipeline became significantly more aligned to real operational pain points.

Conclusion

End-to-end automation isn’t a technology initiative masquerading as strategy. It’s a deliberate effort to reshape how work travels across the organization—who (or what) performs it, when handoffs happen, and how intelligence is injected into the flow. That’s why tools alone don’t move the efficiency needle. Strategy does. The most successful enterprises don’t start with “what can we automate”; they start with “where does work get stuck and why?” Then they build technical capabilities that match that reality. It’s slower in the beginning and occasionally messier. But it produces something most automation programs never achieve: compounding value over time instead of one-off gains.