Key takeaways

- Automating vendor onboarding reduces the cycle time from 10+ days to under 2 days, improving both the supplier experience and internal productivity simultaneously.

- Approval workflows with automation eliminate bottlenecks, bringing down PO approval time from a week to a few hours and ensuring policy compliance.

- Procurement automation ensures real-time integration with ERPs, reducing duplicate data entry and manual errors and improving spend visibility by over 50%.

- Compliance automation provides a comprehensive audit trail, minimizing the risk of non-compliance and enhancing regulatory readiness with real-time alerts and e-signatures.

- Digitizing procurement strategy enhances strategic sourcing, enabling dynamic vendor scoring, automated risk alerts, and continuous visibility into contract compliance.

Procurement is the heartbeat of manufacturing. Yet, despite digital transformation sweeping across industries, procurement processes often remain tethered to outdated, manual operations—especially vendor onboarding and approval flows. A McKinsey report states that over 70% of procurement departments still rely on spreadsheets, emails, and paper forms. The result? Delays, inefficiencies, and compliance risks.

Enter procurement automation. By digitizing vendor onboarding, streamlining approval flows, and aligning strategy through intelligent tools, companies can unlock unprecedented efficiencies. This blog explores the operation of procurement automation, with a specific focus on workflows, impact, and the measurable value it provides to manufacturing enterprises.

The Procurement Process: A Deep Dive

Procurement in manufacturing is more than just buying goods and services — it’s a strategic function ensuring supplier quality, cost-effectiveness, compliance, and risk mitigation. The process typically follows these critical steps:

- Vendor Onboarding — registering and qualifying suppliers to do business.

- Purchase Requests and Approval Flows — ensuring purchases align with budgets and policies.

- Procurement Strategy Execution—applying sourcing rules, vendor evaluation, and compliance monitoring.

Traditionally, these stages have been manual and fragmented, resulting in slowdowns, miscommunication, and compliance issues.

Understanding each stage in detail will help illustrate where automation can add the most value by speeding up operations, reducing errors, and enforcing governance.

Vendor Onboarding: The First Critical Step

Vendor onboarding is foundational to procurement. It involves gathering supplier details, verifying their credentials, and registering them in enterprise systems.

1. Vendor Onboarding

Vendor onboarding is the very first step in the procurement cycle, where new suppliers are registered and qualified to do business with an organization. Traditionally, this onboarding process is highly manual and cumbersome:

- Manual Form Submission: Procurement teams distribute paper or electronic forms that suppliers must complete and return. This could include company details, tax identification numbers, certifications, and other legal documents.

- Document Collection via Email: Suppliers send their completed forms and required documents back via email or other informal channels.

- Manual Verification: Procurement staff manually review these documents to verify tax details, certifications, and compliance requirements.

- Data Entry: Information from forms is manually entered into Enterprise Resource Planning (ERP) systems.

- Waiting for Approvals: The supplier’s registration must be approved by multiple departments, including finance, legal, and procurement, which can often take several weeks.

Why This Is Problematic:

- Delays: Back-and-forth communication can slow the onboarding timeline, sometimes resulting in weeks of waiting.

- Incomplete Documentation: Suppliers may send outdated or partial documents, leading to rework.

- Compliance Risks: Without a proper audit trail, it’s hard to ensure all legal and regulatory requirements are met.

- Human Error: Manual data entry can lead to mistakes that compromise the accuracy of supplier data.

How Automation Transforms Onboarding?

Procurement automation tools digitize and accelerate vendor onboarding.

- Self-Service Vendor Portals:

Suppliers input and upload their data/documents directly into a secure portal. - OCR & AI-Powered Verification:

Optical Character Recognition (OCR) extracts data from uploaded documents; AI checks validity, flags missing info, and verifies compliance. - Automated Workflows:

Once validated, onboarding requests are auto-routed to finance, legal, and procurement approvers, along with notifications and SLA tracking. - ERP Auto-Integration:

Upon approval, vendor data is automatically synced with ERP systems, eliminating the need for manual entry. - Compliance Audit Trails:

All actions, documents, and approvals are time-stamped and stored digitally for audits.

2. Approval Flows: Streamlining Decision-Making

After a vendor is onboarded or when purchase orders (POs) are raised, the process requires approvals from various stakeholders:

- Procurement officers need to check the request.

- Budget owners verify available funds.

- Compliance managers ensure adherence to policy.

- Finance heads approve payment terms and budgets.

Traditional Approval Process:

- Approvals are requested via email chains.

- No centralized dashboard exists to track status in real time.

- Audit trails (who approved what and when) are often incomplete or missing.

- Collaboration is fragmented across email, spreadsheets, and paper.

Challenges Faced:

- Long Approval Cycles: Approval can take 5 to 15 days due to delays in responses.

- Lack of Transparency: Requesters lack visibility into the current approval status.

- No SLA Tracking: Service level agreements for approval times are not monitored, making delays invisible.

- Disjointed Collaboration: Stakeholders may work in silos with no real-time updates.

3. Procurement Strategy Digitization

A procurement strategy encompasses guidelines and policies that govern the selection, evaluation, and management of suppliers, aiming to minimize risk and optimize spending.

Traditional Strategy Execution:

- Policies are often found in static documents or PDFs.

- Vendor evaluations are conducted during periodic meetings.

- Monitoring of vendor performance and compliance is manual.

- Contract management often relies on offline tracking and physical signatures.

Benefits of Digitizing Procurement Strategy:

- Dynamic Rule-Based Sourcing: Automated workflows can enforce procurement rules dynamically, such as preferred supplier lists and spend thresholds.

- Spend Visibility: Real-time dashboards show spend data to ensure compliance with budgets.

- Real-Time Vendor Scoring: Automated scoring models evaluate vendors based on delivery, quality, pricing, and compliance.

- Risk Alerts & Contract Automation: The system can automatically flag risks, such as expiring contracts or non-compliance, and manage digital contracts with e-signatures.

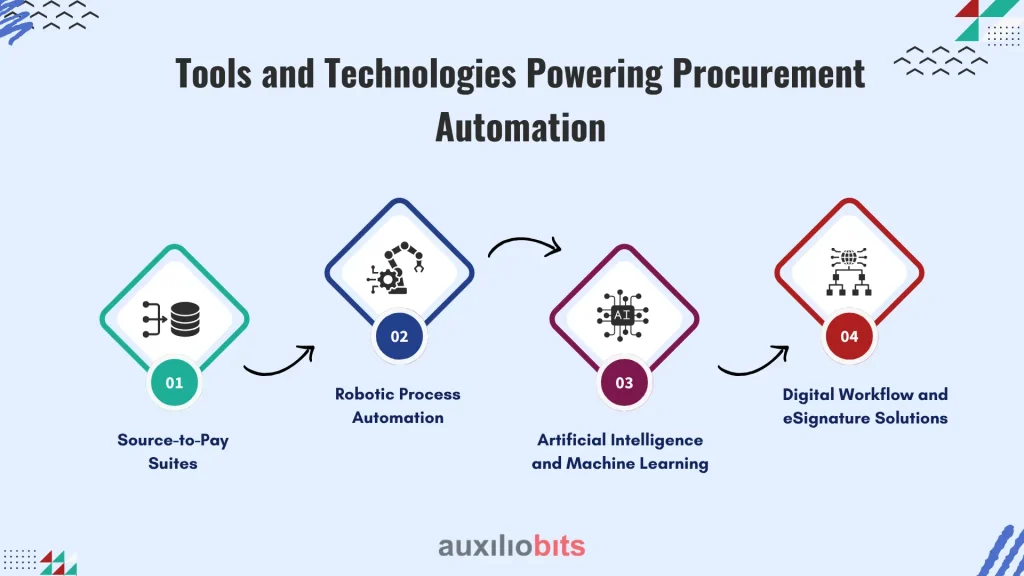

Tools and Technologies Powering Procurement Automation

Procurement automation is transforming the way businesses manage purchasing and vendor relationships by leveraging innovative tools and technologies. These technologies help make procurement faster, more accurate, and less dependent on manual work. Let’s look at the main tools and technologies that power procurement automation today.

Source-to-Pay Suites

One of the most critical tools in procurement automation is the Source-to-Pay (S2P) software suite. These are comprehensive platforms designed to handle the entire procurement process, starting from finding suppliers (sourcing), creating purchase orders, managing contracts, and finally making payments. Popular platforms like SAP Ariba, Coupa, and Jaggaer offer businesses a single platform to manage all procurement activities. These suites help companies stay organized, reduce errors, and keep better control over spending.

Robotic Process Automation

RPA tools, such as UiPath and Microsoft Power Automate, are used to automate repetitive, time-consuming tasks that would typically require manual human intervention. In procurement, RPA robots can automatically extract data from purchase requests or invoices, validate the information, and enter it into the company’s systems without human intervention. This reduces errors, speeds up processing times, and frees up employees to focus on more strategic work instead of routine data entry.

Artificial Intelligence and Machine Learning

AI and ML technologies add a smart layer to procurement automation by helping systems learn and improve over time. For example, AI can automatically classify incoming documents, like invoices or contracts, so they are routed correctly. It can also detect unusual patterns that may indicate fraud or errors. Machine learning models analyze vendor risk by examining past performance, financial health, and compliance data, enabling businesses to select reliable suppliers. AI can even predict how well a supplier is likely to perform in the future, enabling more informed decision-making.

Digital Workflow and eSignature Solutions

Managing approvals and signatures is a big part of procurement. Traditional paper-based approval flows are slow and prone to delays. Digital workflow tools, such as ServiceNow, streamline these processes by creating automated approval chains that notify the right people at the right time. Meanwhile, eSignature solutions like DocuSign enable users to sign contracts and purchase orders electronically in a secure and legally binding manner. This eliminates the need for printing, scanning, and mailing documents, significantly speeding up procurement cycles.

Integration with ERP Systems

Procurement automation does not work in isolation; it tightly integrates with core ERP systems (e.g., SAP, Oracle, Microsoft Dynamics) that manage the company’s financial and operational data.

- Auto-Vendor Master Data Sync: When a vendor completes onboarding, the system automatically creates or updates their profile in the ERP system without manual input.

- Purchase Requisition to PO Creation: Approved purchase requests are seamlessly converted into purchase orders within the ERP.

- Real-Time 3-Way Match: Automated matching of Purchase Order (PO), Goods Receipt Note (GRN), and Invoice ensures accurate payment and detects discrepancies immediately.

Example Workflow:

- A vendor uploads onboarding documents.

- An RPA bot extracts and validates the data.

- The vendor profile is automatically created in the ERP once it has been approved.

- All actions are logged for compliance.

Compliance and Governance

Automation ensures procurement processes are not only efficient but also compliant with internal policies and external regulations.

- Role-Based Access Control: Only authorized users can access sensitive procurement data.

- eSignature Integration: Digital signatures replace physical ones, providing faster and legally binding approvals.

- Automated Alerts: The system triggers alerts for policy violations, such as contract expiry or budget breaches.

- Digital Audit Trails: Every action is logged automatically, creating an immutable record for internal reviews and external audits.

Procurement automation transforms slow, error-prone manual processes into efficient, transparent, and compliant workflows. It enables organizations to onboard vendors more quickly, shorten approval cycles, and digitize the execution of their procurement strategy while integrating deeply with ERP systems for seamless data flow and governance.

Measuring the Impact: KPIs and ROI of Manual Procurement Challenges

Procurement is a vital business function that involves companies purchasing goods and services from vendors. However, many organizations still rely heavily on manual procurement processes. These manual processes present several challenges that impact efficiency, accuracy, and costs. To understand how procurement automation can help, it’s essential to examine the typical challenges of manual procurement and measure their impact through key performance indicators (KPIs) and return on investment (ROI).

Let’s explore some common activities in manual procurement, the time they take, their error rates, and the costs involved.

1. Vendor Onboarding

Vendor onboarding is the process of bringing a new supplier into the company’s system. This includes collecting and verifying essential documents, such as certifications, tax information, contracts, and bank details.

- Time Taken: In manual processes, onboarding a vendor typically takes 7 to 15 days. This is because teams must collect paperwork, verify its accuracy, and manually enter data into various systems. Any missing or incorrect information often causes delays.

- Error Rate: There is usually an error rate of 10% to 15% during vendor onboarding. Errors may include incomplete documents, incorrect data entries, or missing approvals, which can create rework and further slow down the process.

- Cost per Transaction: Onboarding a single vendor manually can cost between $80 and $100 per transaction. These costs stem from the labor involved in handling paperwork, validation, and communication with vendors.

Because onboarding is slow and error-prone, it affects how quickly a business can start working with a new supplier, potentially delaying projects and operations.

2. Approval Flow

Once vendors are onboarded or purchase requests are created, they need to be approved by the relevant managers or departments.

- Time Taken: Manual approval flows often take 5 to 10 days. The approval process usually involves routing paper forms or emails between multiple people, waiting for their sign-off. Any delay or unavailability of approvers extends this time.

- Error Rate: Approval errors, such as missing signatures or approvals from the wrong authorities, occur in approximately 5% to 10% of transactions. These errors cause further delays and can lead to non-compliance or unauthorized purchases.

- Cost per Transaction: The cost of processing approval flows manually ranges from $50 to $70 per transaction. This includes staff time spent chasing approvals, tracking documents, and correcting mistakes.

Slow approvals create bottlenecks, increasing the cycle time from purchase request to order placement, which can impact supply chain efficiency and business responsiveness.

3. Compliance Audit

Compliance audits ensure that procurement activities meet legal, regulatory, and company policy requirements. Audits verify that vendors are appropriately contracted, contracts are followed, and spending is within budget.

- Frequency: Many organizations conduct compliance audits quarterly or on a scheduled basis.

- Effort Involved: Manual audits require significant effort — gathering documents from various departments, cross-checking records, and manually verifying approvals. This is a time-consuming and labor-intensive process.

- Cost per Year: The cost of manual compliance audits often exceeds $10,000 per year. These costs come from staff hours dedicated to audits, external auditor fees, and the risk of penalties if non-compliance is found.

Without automation, audits are not only expensive but also less effective because errors and gaps may be missed, leading to risks for the company.

Why Measure KPIs and ROI?

KPIs (Key Performance Indicators) are metrics used to evaluate the efficiency and effectiveness of procurement processes. The typical KPIs in manual procurement include cycle time (the duration of a task), error rate (the frequency of mistakes), and cost per transaction (the expense incurred to complete a task).

ROI (Return on Investment) measures the financial benefits gained from investing in procurement automation versus the costs incurred in the manual process.

By tracking key performance indicators (KPIs) such as time delays, error rates, and high costs in manual procurement, organizations can pinpoint areas where automation can save money and enhance performance. For example:

- Reducing vendor onboarding time from 15 days to 2 days can speed up project start times.

- Lowering errors from 15% to 1% means less rework and fewer delays.

- Cutting approval cycle times and associated costs improves overall procurement efficiency.

- Automating compliance audits reduces audit costs and improves risk management.

Conclusion

Manual procurement processes are slow, costly, and prone to errors. The table below summarizes the typical challenges:

| Activity | Manual Time | Error Rate | Cost per Transaction |

| Vendor Onboarding | 7–15 days | 10%–15% | $80–$100 |

| Approval Flow | 5–10 days | 5%–10% | $50–$70 |

| Compliance Audit | Quarterly effort | High effort | $10,000+ per year |

Measuring these KPIs helps businesses identify the pain points in their procurement process and the potential savings that can be achieved through automation. Investing in procurement automation technology can significantly reduce time, errors, and costs, leading to stronger vendor relationships, enhanced compliance, and increased overall business efficiency.

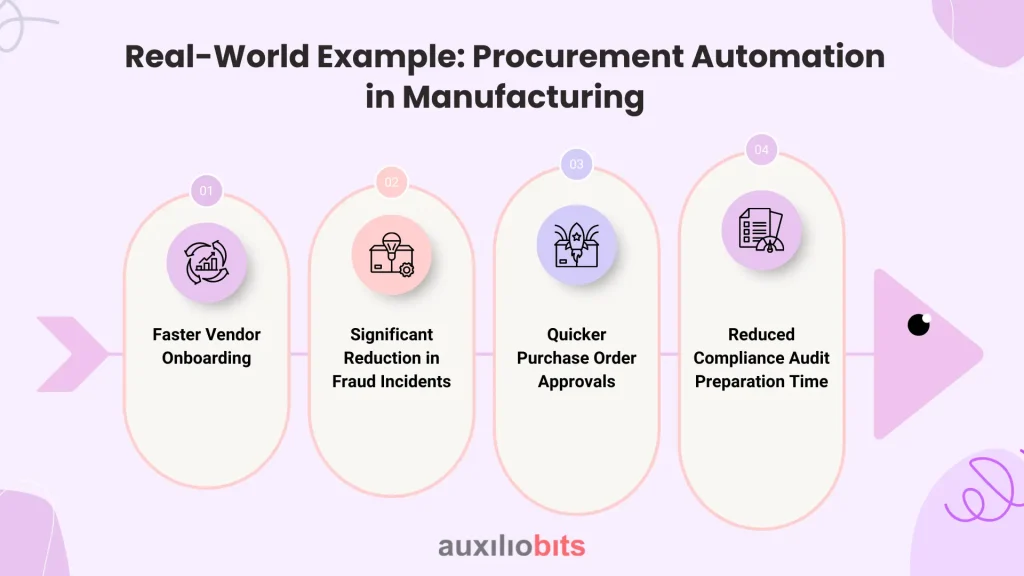

Real-World Example: Procurement Automation in Manufacturing

Let’s look at how a real automotive manufacturer improved its procurement process by using automation technologies.

This company combined three powerful tools: SAP Ariba (a comprehensive procurement platform), Microsoft Power Automate (an RPA tool for automating repetitive tasks), and Artificial Intelligence (AI) for verifying vendor information.

Here’s what happened after they implemented this integrated automation solution:

1. Faster Vendor Onboarding

Before automation, onboarding a new vendor took about 12 days. The process involved manually collecting and verifying documents, which was slow and prone to mistakes.

With the new system automating data collection and verification, onboarding time dropped dramatically to just 2 days. This enabled the company to initiate collaboration with suppliers more efficiently, thereby accelerating production and minimizing delays.

2. Significant Reduction in Fraud Incidents

Manual onboarding processes often allow errors or fraud to slip through due to limited checks.

After adding AI-powered verification, the company saw an 80% reduction in onboarding fraud incidents. The AI could quickly detect suspicious or inconsistent information, helping to prevent fraudulent vendors from entering the system and reducing risk.

3. Quicker Purchase Order Approvals

Previously, the purchase order approval cycle took about 10 days. Managers had to review and sign off manually, often waiting for emails or physical documents.

By automating approval workflows with Power Automate and digital signatures, the approval cycle was shortened to just 1 day. This accelerated purchasing decisions, enabling the company to respond more quickly to material needs and market changes.

4. Reduced Compliance Audit Preparation Time

Preparing for compliance audits manually involved gathering documents, cross-checking approvals, and verifying records, which required a significant amount of time and effort.

With automated document management and real-time audit tracking, the company cut compliance audit preparation time by 60%. This freed up resources and improved audit accuracy.

Overall Impact

This transformation didn’t just speed up tasks — it also improved supplier relationships because vendors experienced faster onboarding and more transparent communication. Internal collaboration became smoother as teams no longer wasted time chasing paperwork.

Most importantly, these improvements enabled the company to save costs, mitigate risks related to fraud and compliance, and operate more efficiently in a highly competitive market.

Conclusion

Procurement automation is not just a nice-to-have but a strategic imperative for manufacturing enterprises seeking agility, transparency, and compliance in their supply chains. By digitizing vendor onboarding, streamlining approval workflows, and transforming procurement strategy execution with intelligent automation tools, companies can unlock significant cost savings, accelerate time-to-value, and mitigate risks.

The key lies in selecting the right mix of tools, integrating them seamlessly with ERP systems, and continuously monitoring key performance indicators (KPIs) to ensure sustained benefits. As manufacturing evolves in the digital age, procurement automation will be a critical lever for competitive advantage.