Key Takeaways

- Analyzing past shipping records reveals patterns in cost, delays, and carrier performance, enabling smarter, data-driven freight decisions and long-term cost savings.

- AI dynamically responds to disruptions like traffic or weather, optimizing routes and carriers instantly to reduce costs and enhance delivery reliability.

- AI evaluates cost and reliability, delivery speed, and hidden fees, helping businesses choose the best overall carrier for long-term performance.

- AI suggests consolidating smaller shipments to reduce trips, fuel use, and handling costs, maximizing efficiency, and leveraging bulk shipping discounts.

- Businesses can start freight optimization with simple data collection and a user-friendly AI tool, gaining actionable insights quickly without needing deep technical expertise.

Managing shipping and logistics is key to staying competitive in today’s business world, especially if you sell or move physical goods. High shipping costs can quickly reduce your profits, whether you’re a manufacturer, an online store, or a retailer. But what if you could plan better, predict costs, and even cut down on those expenses without slowing deliveries or lowering service quality?

That’s where historical data and artificial intelligence come in. By using past shipping records—like delivery times, fuel prices, weather patterns, and customer demand—AI can help you make smarter choices. It can spot trends and patterns that humans might miss, like which routes are cheaper, which carriers are more reliable, or when to ship to avoid delays and high costs.

AI tools can also adjust in real time. For example, AI can suggest a better route or carrier if a traffic jam, storm, or fuel price spike occurs. This means fewer delays, lower costs, and happier customers.

In short, using AI and data lets businesses control freight decisions, improve planning, and save money without stress. It’s a smart move for any company that wants to stay efficient and competitive.

Also read: Cost Optimization in Finance: AI for License Auditing and Rationalization.

What Is Freight Cost Optimization?

reight cost optimization is shipping your goods cost-effectively while meeting delivery deadlines and keeping your customers happy. It’s all about finding the right balance between saving money and delivering on time.

To do this, businesses look at several things:

- Choosing the right carriers: Not all shipping companies charge the same or offer the same service. It is essential to pick the one that gives you the best value.

- Picking the best routes: Some routes are faster or cheaper than others, depending on traffic, tolls, fuel costs, and distance.

- Consolidating shipments: Instead of sending many small packages, combining them into one larger shipment can save money.

- Avoiding extra fees: Late deliveries, fuel surcharges, or last-minute changes can incur additional costs. Planning helps avoid these.

In the past, logistics managers handled all this manually. They used spreadsheets; their experience and gut feeling greatly depended on them. This took a lot of time and often led to errors or missed savings. Today, things are different. Companies can make faster and smarter decisions with artificial intelligence and data analytics. These tools can quickly analyze vast amounts of data, like delivery times, costs, weather, and demand, and suggest the best shipping options. AI can even predict problems. For example, if a storm is coming or fuel prices increase, the system can mean a different route or carrier to keep costs low.

In short, freight cost optimization helps businesses save money, avoid delays, and deliver better service. And with modern technology, it’s easier and more accurate than ever.

The Role of Historical Data

Historical data means all the past information you’ve collected about your shipments over time. This includes things like:

- How much did you pay for each shipment

- Which carriers (shipping companies) did you use

- How fast shipments were delivered, and if there were delays

- Extra charges, like fuel surcharges or hidden fees

- The size, weight, and number of items shipped

- Where your customers are located

Although all this information might seem simple, it can tell a powerful story when analyzed together. By analyzing this data, you can find patterns, problems, and ways to save money on future shipments.

For example, one carrier is always more expensive for a specific route, even though another carrier delivers just as fast or even faster. Or specific shipping routes always have delays, causing late deliveries and unhappy customers. You might also find that you’re not taking advantage of bulk shipping discounts because you’re sending too many small packages instead of combining them.

Here’s how historical data helps:

- Compare carrier performance: You can see which shipping companies are the most reliable and cost-effective.

- Spot common delays: If delays happen often in certain areas or during certain times of the year, you can plan around them.

- Understand shipping trends: Shipping costs rise in certain regions, or you ship more during certain months. This helps with future planning.

- Avoid hidden fees: If you notice frequent extra charges, you can work with your carriers to avoid them or change how you ship.

- Improve delivery times: Looking at delivery history helps you choose faster or more reliable options.

Using tools like AI and data analytics, you don’t have to look at all this data manually. The system can scan your historical data and instantly highlight what’s working and what’s not.

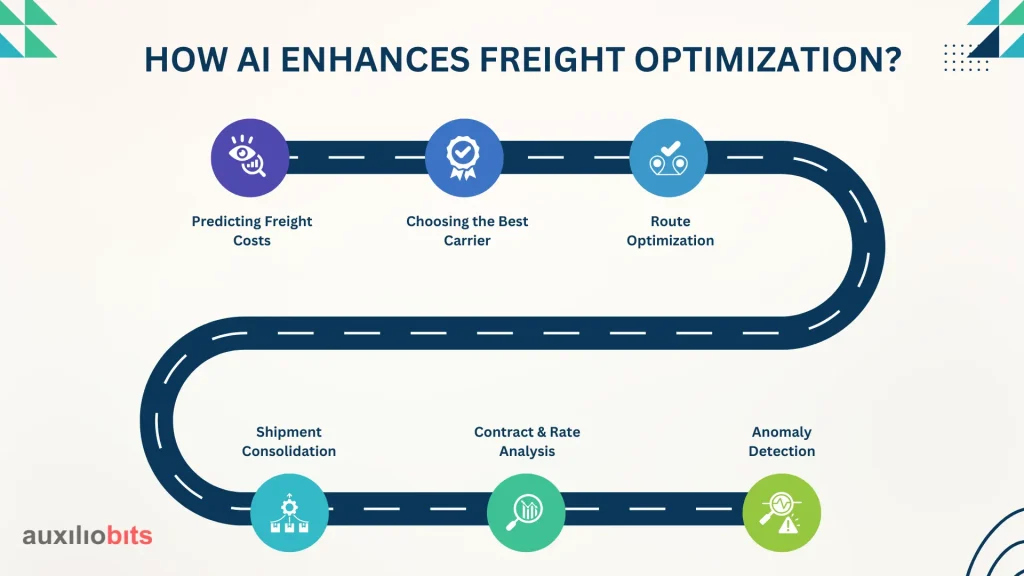

How AI Enhances Freight Optimization?

Artificial Intelligence is changing the way businesses handle shipping and freight. While historical data helps you understand past events, AI takes things to the next level by allowing you to predict, plan, and make smarter decisions in real time. It does tasks that are too complex or time-consuming for people to do manually and does them fast and accurately.

Here are some of the key ways AI helps with freight cost optimization:

1. Predicting Freight Costs

AI looks at your past shipment data and predicts how much future shipments might cost. It takes into account:

- Distance of the shipment

- Size and weight of the goods

- Fuel prices (which can change often)

- Time of year (some seasons are more expensive due to high demand)

This helps your business plan better. You can set more accurate shipping budgets and avoid surprise costs. For example, AI might predict that shipping in December will be 20% more expensive due to holiday demand, so you can ship earlier and save money.

2. Choosing the Best Carrier

AI doesn’t just look at prices. It compares shipping companies based on:

- How often do they deliver on time

- How many packages do they damage or lose

- What extra fees do they charge (like fuel or weekend delivery fees)

This gives you a complete picture—not just who’s cheapest but most reliable. You can make more intelligent choices and improve customer satisfaction by picking the right carrier.

3. Route Optimization

AI tools can find the fastest or cheapest shipping routes. It checks:

- Real-time traffic updates

- Road closures

- Weather conditions

AI can reroute the shipment instantly if there’s a storm or traffic jam. This means your goods arrive faster, and you spend less on fuel or delay penalties.

4. Shipment Consolidation

If you send many small shipments to the same area, AI can suggest combining them into one larger load. This is called shipment consolidation. It helps:

- Reduce the number of trips

- Lower fuel and handling costs

- Take advantage of bulk shipping discounts.

This can make a big difference, especially for businesses that ship daily or weekly.

5. Contract & Rate Analysis

Reading through carrier contracts can be complex and time-consuming. AI can quickly scan these documents and point out:

- Hidden fees or costly terms

- Better rates offered by other carriers

- Opportunities to renegotiate existing contracts

This helps you avoid overpaying and keeps your contracts fair and competitive.

6. Anomaly Detection

Sometimes a shipment costs much more than expected. There may have been an error, a surcharge, or a delay. AI can instantly detect and alert you when something looks unusual. It can also explain what went wrong, so you can fix it quickly and avoid it.

Steps to Get Started with AI for Freight Cost Optimization

You don’t need to be a tech expert or a large company to start using AI to improve your shipping and logistics. With the proper steps and tools, any business can use artificial intelligence (AI) to save money and make smarter freight decisions. Here’s a simple step-by-step guide to help you get started:

Step 1: Collect Historical Data

Before AI can help, it needs data to learn from. Start by gathering at least 6 to 12 months of your shipping history. The more data you have, the better the results.

You should collect:

- Shipping invoices (to track costs)

- Carrier performance reports (on-time delivery, damage, customer feedback)

- Delivery times (how long shipments take)

- Shipment details (weight, size, origin, destination)

- Fuel surcharges and other fees

This data might already be in your systems, like Excel files, shipping software, or accounting tools. Make sure it’s accurate and complete.

Step 2: Use an AI-Powered Logistics Tool

Once you have the data, you’ll need an analysis tool. Many user-friendly platforms use AI to help businesses with freight optimization. Some of the popular ones include:

- FourKites—for real-time shipment tracking and analytics

- Project44—for supply chain visibility and route optimization

- Power BI or Tableau—for custom dashboards that can include AI models

You can use a ready-made platform or ask a tech expert to help set up a custom dashboard that suits your business needs.

Step 3: Identify Opportunities for Improvement

Now the fun part is to let the AI tool scan your data and show you where you can improve. These tools can quickly find:

- Overpriced routes—where you’re paying more than needed

- Low-performing carriers—companies that are often late or damage goods

- Shipment consolidation opportunities—combining smaller deliveries into larger ones to save money

The AI will show these insights in simple charts or suggestions, so you don’t need to be a data scientist to understand them.

Step 4: Make Data-Driven Decisions

Use the insights from the AI tool to change your shipping strategy. This might include:

- Negotiating better rates with carriers who want your business

- Switching to more reliable or cost-effective carriers

- Planning better routes based on traffic, cost, and delivery time

- Consolidating shipments to save on fuel and handling fees

These small changes can lead to significant savings over time.

Step 5: Monitor and Improve Continuously

AI works best when it keeps learning. So don’t stop after the first round of changes. Keep feeding new shipping data into the system regularly.

- Track performance monthly or quarterly

- Compare actual costs vs. predicted costs.

- Watch for new opportunities or issues.

The more you use the system, the smarter it gets—and the more money and time you save

Getting started with AI in freight optimization is easier than it sounds. With the correct data and tools, you can improve delivery times, cut costs, and make your logistics smoother. It’s a smart step forward for any business that ships goods.

Conclusion

Freight cost optimization isn’t just about saving money—it’s about building a smarter, more efficient supply chain. Using your historical shipping data and the power of AI, you can make better decisions, avoid costly mistakes, and deliver a better experience for your customers.

Small changes—like switching carriers or consolidating shipments—can lead to significant savings over time.

So, start small, think smart, and let data guide you.