Key takeways

- The supply chain involves a myriad of activities and multiple stakeholders. The complex network of activities must function seamlessly for hassle-free supply chain execution.

- Legacy systems face several bottlenecks that cause delays and glitches in supply chain management leading to poor customer experience.

- Emerging technologies like Robotic Process Automation(RPA), Artificial Intelligence(AI), the Internet of Things (IoT), Big data, etc., are effective in resolving most shortcomings of manual supply chain management.

- Automation makes the supply chain agile and resilient.

The supply chain includes all the processes from sourcing raw materials to manufacturing and shipping to the customers. This involves a myriad of activities and multiple stakeholders. Perfect functionality of each process is imperative for seamless supply chain execution. This implies that each process must run without delays and glitches. In the real world, this is almost impossible. A dysfunctional supply chain can directly impact the productivity and profitability of the business.

Some of the Common Challenges a Typical Supply Chain Faces are

- A typical supply chain involves several stakeholders such as a contract manufacturer, a third-party testing facility, a storage facility, and a freighting company. Seamless collaboration between these entities is imperative for an effective supply chain. Collaboration between stakeholders has been an issue in supply chain management.

- In any supply chain, there is a sequence of processes that need to complete in a specific timeframe. A delay in any of these processes has a domino effect impacting all other processes. It directly impacts the costs of operations of each process.

- One of the biggest pitfalls of manual supply chain systems is poor visibility of operations which leads to supply chain disruptions because of inaccurate forecasting. Businesses need accurate data to manage the volatile supply chain dynamics. Accurate demand forecasts will enable businesses to have the right product in the right quantities. It will directly impact fill rates and service levels. These factors will boost revenues and reduce costs.

- Another critical factor is sales and operation management. Optimizing sales and operations planning can enhance profitability.

- The supply chain involves a sequence of operations that need to run in tandem. A problem in any one of the operations can impact the efficacy and increase costs. Predicting bottlenecks and delays and resolving them helps streamline the process. However, in legacy systems, predicting unforeseen issues is time-consuming and difficult.

- Most businesses find it difficult to cope with the changing demand patterns of consumers. Changing buyer demands directly impact each element of the supply chain.

- Once the goods are manufactured, the organization has to decide where to send, how much to send, and through which channels to send to minimize logistics delays and costs. Managing all these aspects can be time-consuming which can delay deliveries. This offers a poor customer experience.

Emerging technologies like Robotic Process Automation(RPA), Artificial Intelligence(AI), the Internet of things(IoT), Big data, etc. are effective in resolving most shortcomings of manual supply chain management.

While technology can optimize several aspects of supply-chain management, human intervention is still required for a seamless supply chain. Automation bots can assist humans to enhance the efficacy of the supply chain.

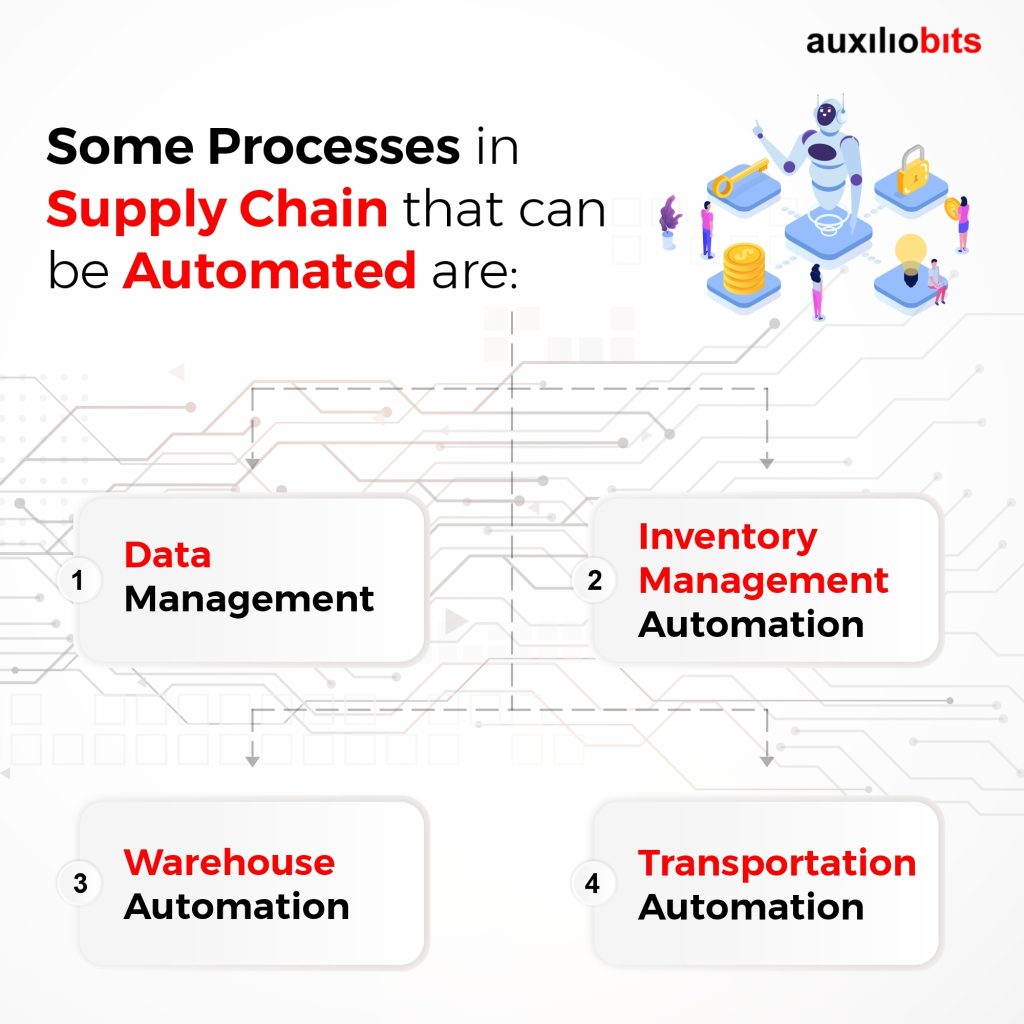

Some Processes in Supply Chain that can be Automated are

1. Data Management

Software tools facilitate extracting data from Purchase Orders into the software. Automation of supply chain analytics helps businesses keep track of key business metrics. It reduces the time and effort required for data collection and number crunching.

Digitization using technologies like Big data provides valuable insights that help in decision making. Machine learning algorithms review historical data for accurate demand forecasting and procurement. Cognitive analytics automation facilitates quick and seamless decision-making.

Artificial Intelligence facilitates accurate demand forecasting. It helps in the effective management of demand variability and sourcing

2. Inventory Management Automation

Inventory management requires human intervention. However, certain aspects of inventory management can be automated using bots.

Automation software provides reorder point alerts when the threshold amount for a Stock Keeping Unit (SKU) is reached. This helps supply chain professionals plan replenishment and prevent stockout and backorders.

Robotic Process Automation can also be leveraged to automate the entire restocking process. Bots automatically reorder stock when an SKU reaches its threshold. This speeds up the process and reduces effort.

3. Warehouse Automation

In today’s market, buyers expect a quick turnaround from businesses. As such businesses need to maintain and manage a large number of SKUs. This will require a lot of resources. Intelligent automation of warehouses is an effective way to manage this problem with minimum resource requirements.

The predictive analysis aspect of Ai optimizes inventory levels, eliminates waste, and replenishes inventory.

Autonomous Guided Vehicles like forklifts, automated stackers, small rack-carrying robots, etc. offer time and labor efficiency. Technologies like Machine Learning(ML) and deep learning can be leveraged to execute material handling tasks.

Some warehouse automation software also includes features to determine the best space to store inventory. This optimizes space utilization and enhances picking efficiency.

4. Transportation Automation

Fleet management is a vital element of logistics. Automated trucking solutions enhance the efficiency of the transportation system. Fleet management automation provides insights such as fuel efficiency, fuel loss, etc. AI and ML can be deployed to enhance driver efficiency, prevent accidents, improve fuel efficiency, reduce logistics delays, and facilitate predictive maintenance.

Route automation software reduces transit time and shipping costs by determining the best route and assigning the most optimum carrier for shipments. AI facilitates real-time tracking of shipments and provides actionable data to a business. This data can help one assess any delays in transportation and optimize them thereby minimizing operational costs and transit times.

Why you Must Automate your Supply-chain?

One major factor that restricts businesses from implementing automation is the cost. Many business leaders feel that automation requires high investment. It is important to understand that although the initial investment for automating the supply chain is high, the ROI is quite high.

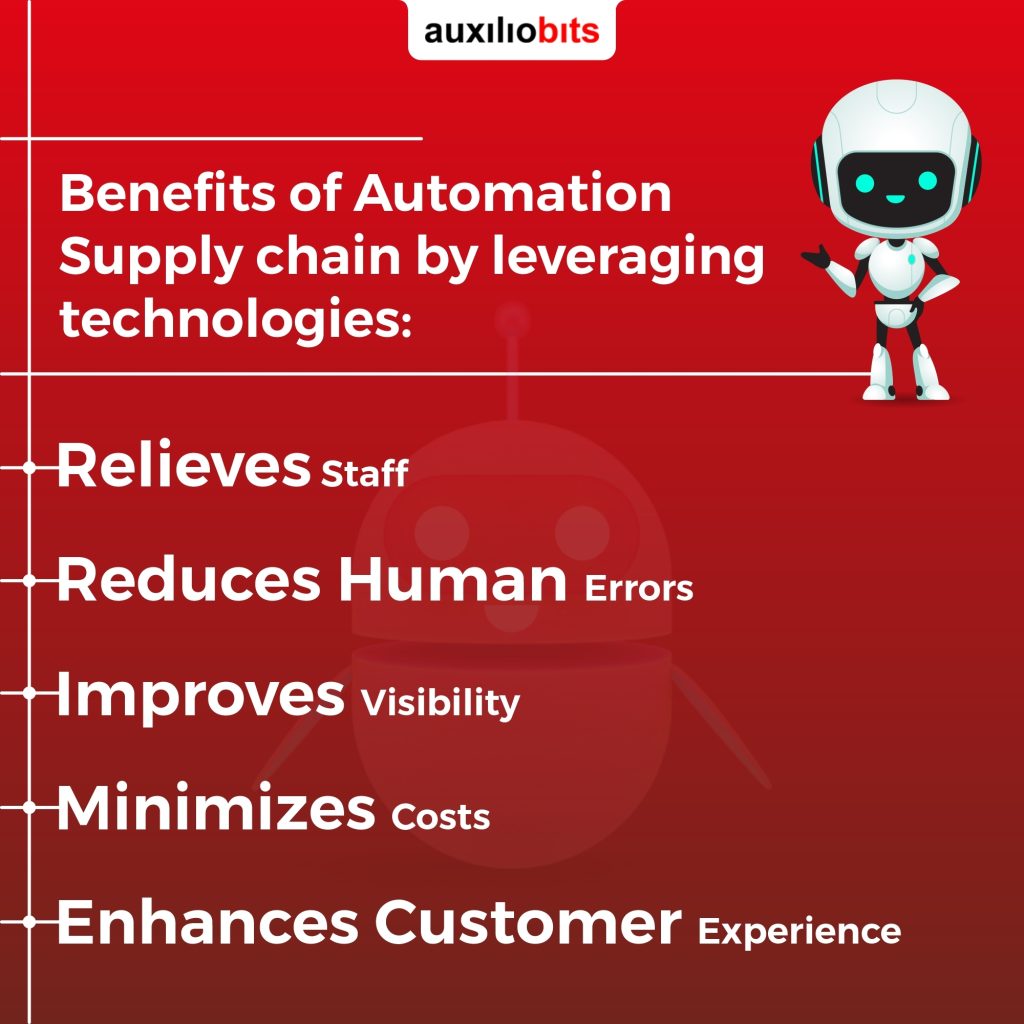

Automation of the supply chain by leveraging technologies like RPA, AI, ML, etc. offers the following benefits that justify the expenses incurred

1. Relieves Staff

Repetitive processes such as generating documents, processing orders, payment of invoices, etc. are time-consuming and require the efforts of several professionals. RPA bots can automate these tasks relieving professionals of tasks that require human intelligence. This, in turn, enhances supply chain efficiency.

2. Reduces Human Errors

When different processes in the supply chain are performed manually, they are prone to human errors, which can sometimes prove to be very costly. Automation software eliminates human errors and improves accuracy.

3. Improves Visibility

Maintaining supply chain visibility enhances its efficacy. However, in manual systems, visibility is difficult to maintain. Besides, it requires labor, communication, connectivity, and collaboration between various stakeholders which is difficult to achieve. Automation software records and updates the systems in real time. This enables different stakeholders to access data from a central platform. It also streamlines collaboration.

Better visibility also helps identify bottlenecks in the supply chain and resolve them to prevent delays and disruptions.

4. Minimizes Costs

Supply chain management is a labor-intensive function. Besides, a manual supply chain is vulnerable to errors and delays. Factors such as these increase the cost of operation. Automation of supply chain processes not only saves time and effort but also costs associated with rework due to errors.

Also, AI provides accurate demand forecasts which facilitate better inventory management. It reduces the costs associated with storage and logistics functions of inventory.

5. Enhances Customer Experience

The ultimate objective of any business is to delight its customers. This is possible only when the business can fulfill the demands of the buyer. In other words, provide the buyer with what he wants at the right time and the right place. Automated supply chains run seamlessly with minimal delays and can meet customer demands.

When it comes to automating the supply chain, there are many doubts in the minds of business leaders.

There are questions like,

Is technology compatible with suppliers and customers?

Will technology become obsolete?

Will it require the support of the vendor?

Will it require constant monitoring and maintenance?

In case you have any queries regarding the automation of your supply chain, connect with the experts at Auxiliobits!

Why Auxiliobits Supply Chain Automation is the Best for your Organization?

- We provide a customized supply chain solution based on your organizational goals.

- Our professional team assesses your existing systems and technical capacities and develops solutions that can be easily integrated with your existing system.

- We have several years of experience in successfully implementing supply chain automation solutions.

- We offer cost-effective automation solutions for your business.

- We offer scalable automation models.

- Our strategic automation solutions optimize cost and time.

In Conclusion

Automation breaks away from siloed supply chain models and provides digital solutions that can react faster, maximize value, and predict accurately. Bots make the supply chain system agile so that it can respond quickly to changes in a dynamic marketplace!

Watch this space for more on process automation solutions by Auxiliobits!

April 15, 2024

April 15, 2024